Lamp holder and manufacturing method thereof

A lamp holder and spiral lamp holder technology, which is applied in the direction of incandescent lamps, discharge lamps, incandescent lamp parts, etc., can solve the problems of low processing efficiency, excessive metal materials, waste of resources, etc., and achieve high processing efficiency and less metal materials , the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

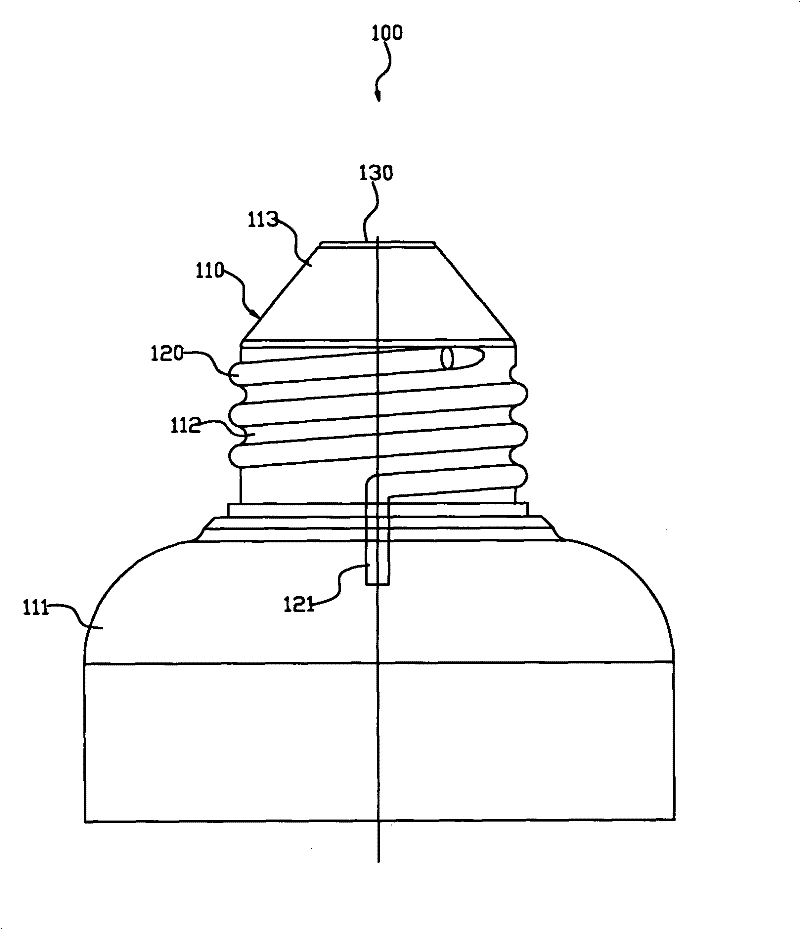

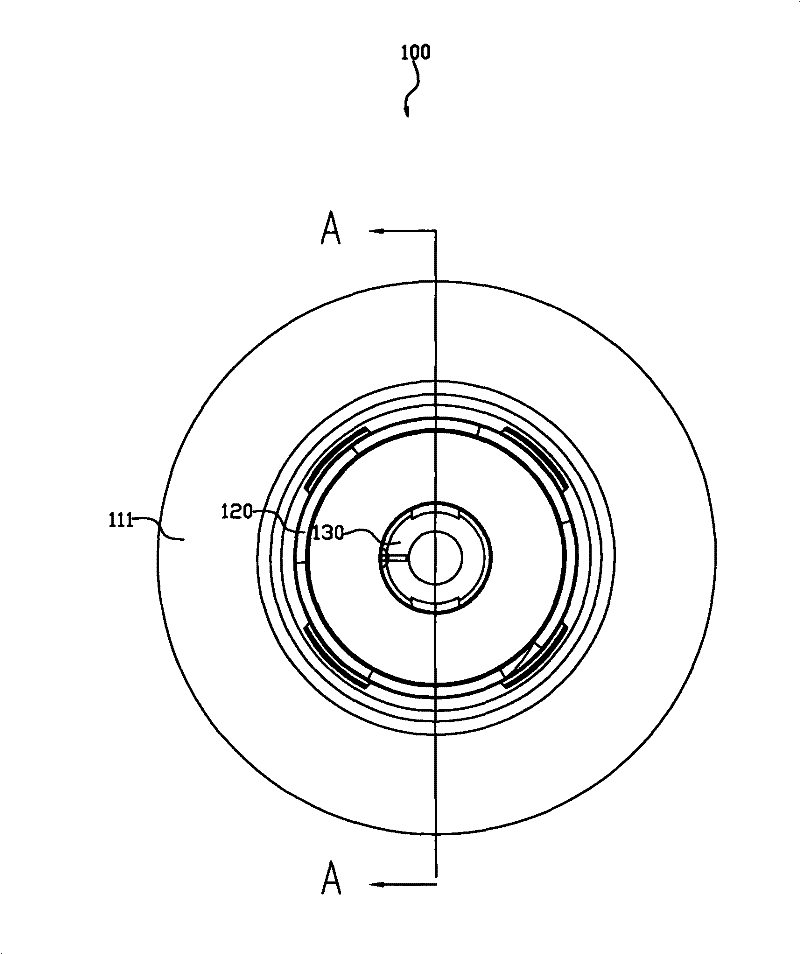

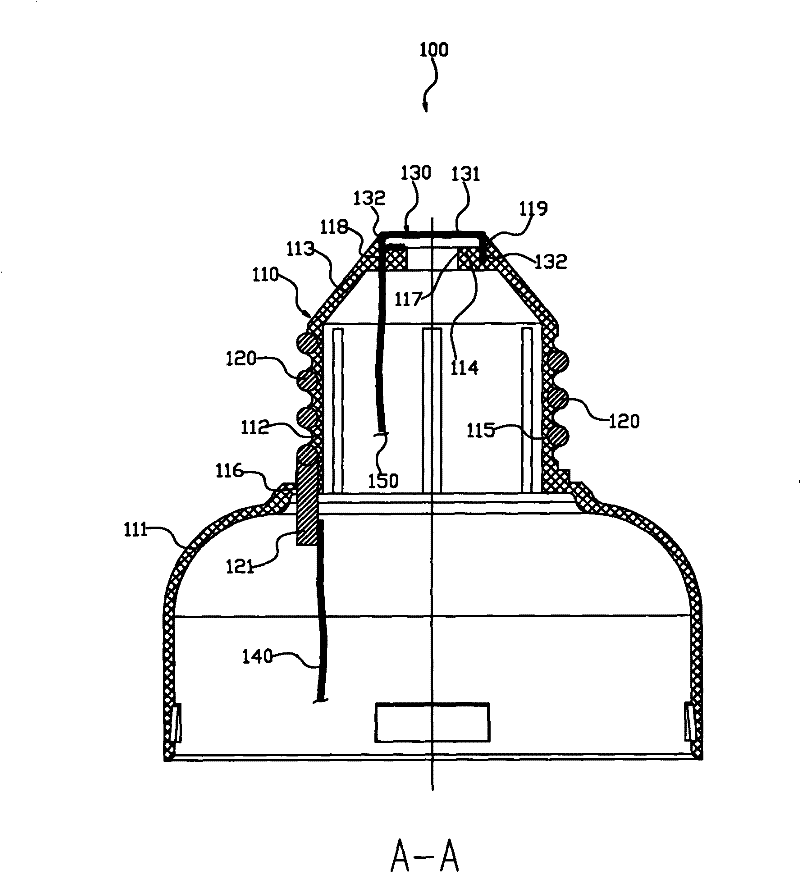

[0033] Please check figure 1 , figure 2 and image 3 , a lamp holder 100, which includes a plastic rotary shell 110, a spiral conductive wire 120, a conductive cap 130, a side line 140 and a center line 150.

[0034] The rotary housing 110 is integrally formed, and it includes a skirt body 111, a cylindrical sleeve wall 112 connected to the skirt body 111, a circular frustum sleeve wall 113 connected to the cylindrical sleeve wall 112, and a cylindrical sleeve wall 113 fixed on the circular frustum sleeve. The top wall 114 within the top periphery of the wall 113. In this embodiment, the rotatable housing 110 is integrally formed, but it is not limited thereto. Other rotatable housings 110 composed of detachable upper and lower housings are also applicable to this embodiment. A spiral groove 115 is provided outside the cylindrical sleeve wall 112, and a first through hole 116 that runs through the inside and outside of the rotary housing 110 is opened at the joint between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com