Engine system and method for substantially NOx-free combustion of a fuel in a compression ignition engine

An engine system and engine technology, applied in combustion engines, internal combustion piston engines, engine components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

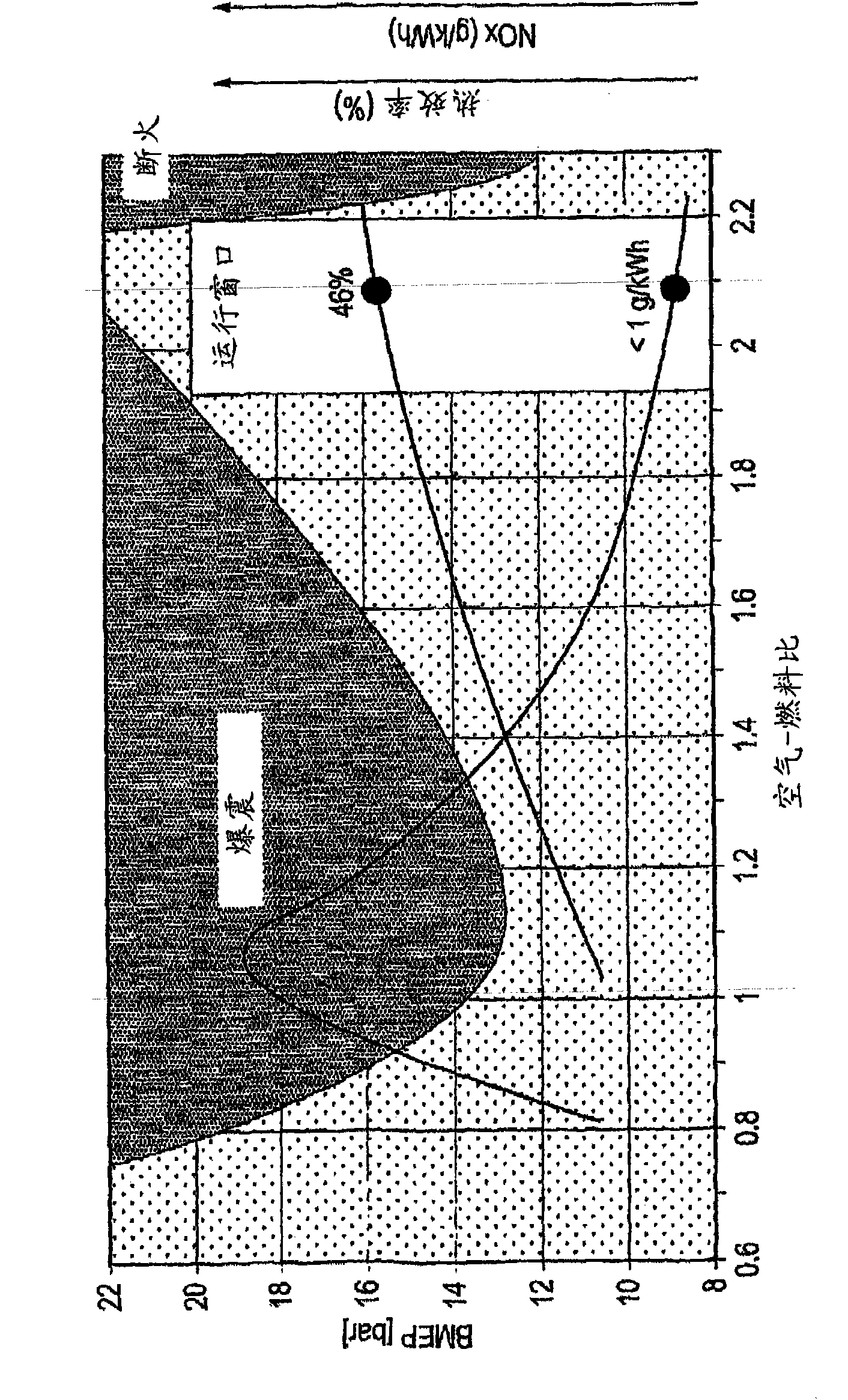

[0033] exist figure 1 , showing the Work done on large dual fuel marine engines. This figure shows the operating window where it can be seen that by providing a lean mixture of fuel and air, the compression ratio can be increased without self-knock or misfire.

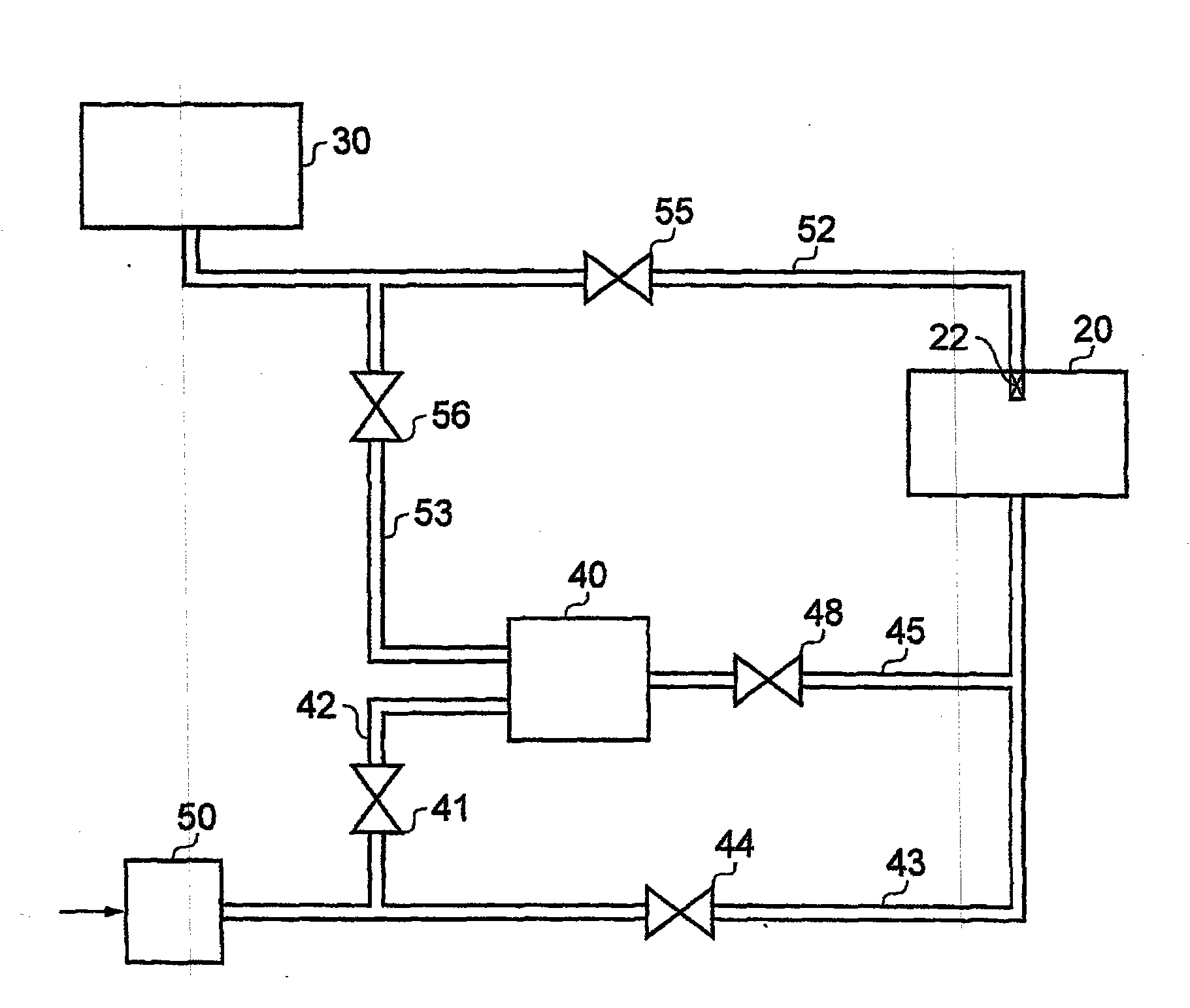

[0034] Embodiments of the present invention are in figure 2 shown schematically. A cold flame evaporator 40 is provided in which fuel is partially oxidized in preheated air to form cold flame gas. The resulting cold flame gas is a gaseous, homogeneously mixed fuel.

[0035] An air source 50 is also provided, which is connected by fluid line 42 to the cold flame vaporizer. Valve means 41 are provided to control the flow of air from an air source 50 to the cold flame vaporizer 40 .

[0036] A fuel source 30 for supplying diesel or heavy fuel oil is also provided. Fuel source 30 is connected to the cold flame vaporizer by fluid line 53 . Valve arrangement 56 controls the flow of fuel to cold flame vaporizer 40 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com