Orbit of gas shielded welding automatic welding trolley in offshore steel structure

A gas-shielded welding and automatic welding technology, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of no installation and positioning reference, inability to meet horizontal welding, and inaccurate installation and positioning, and achieve good stability and structure. Simple and lightweight, fast and accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

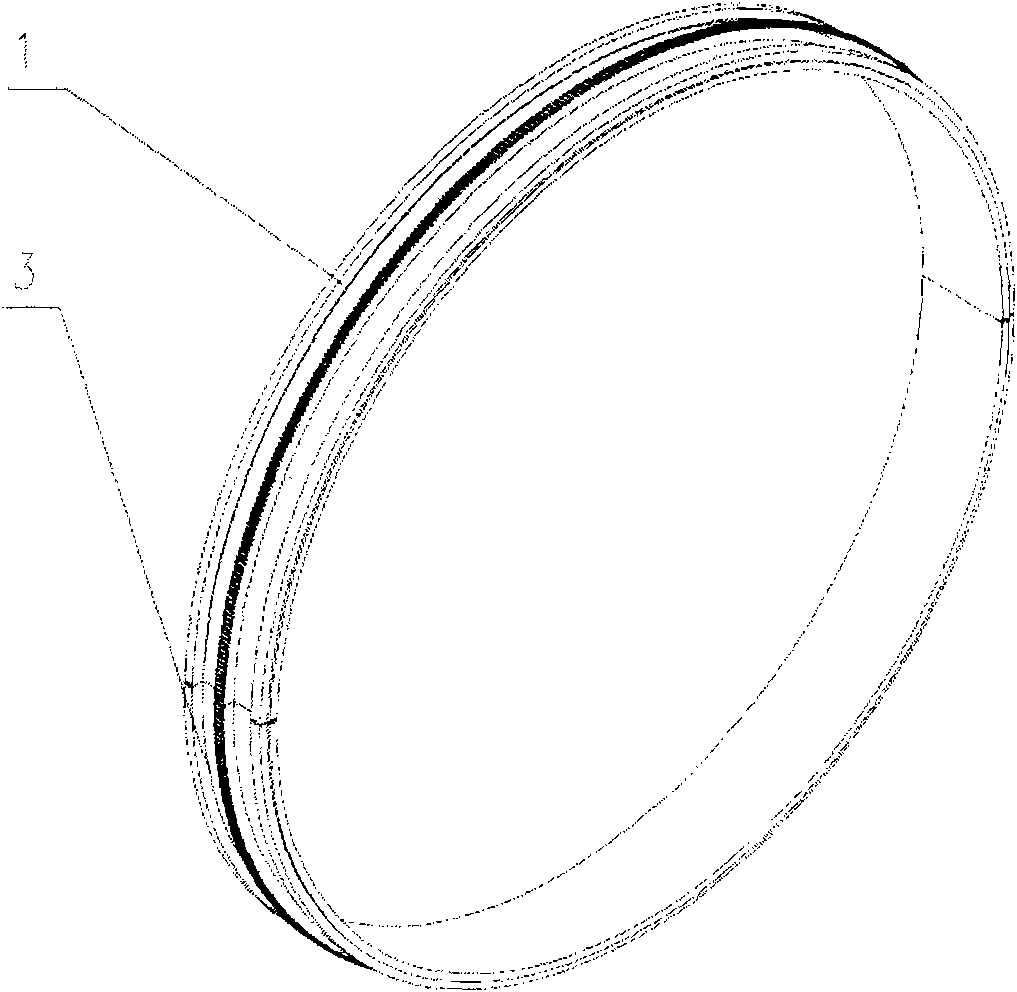

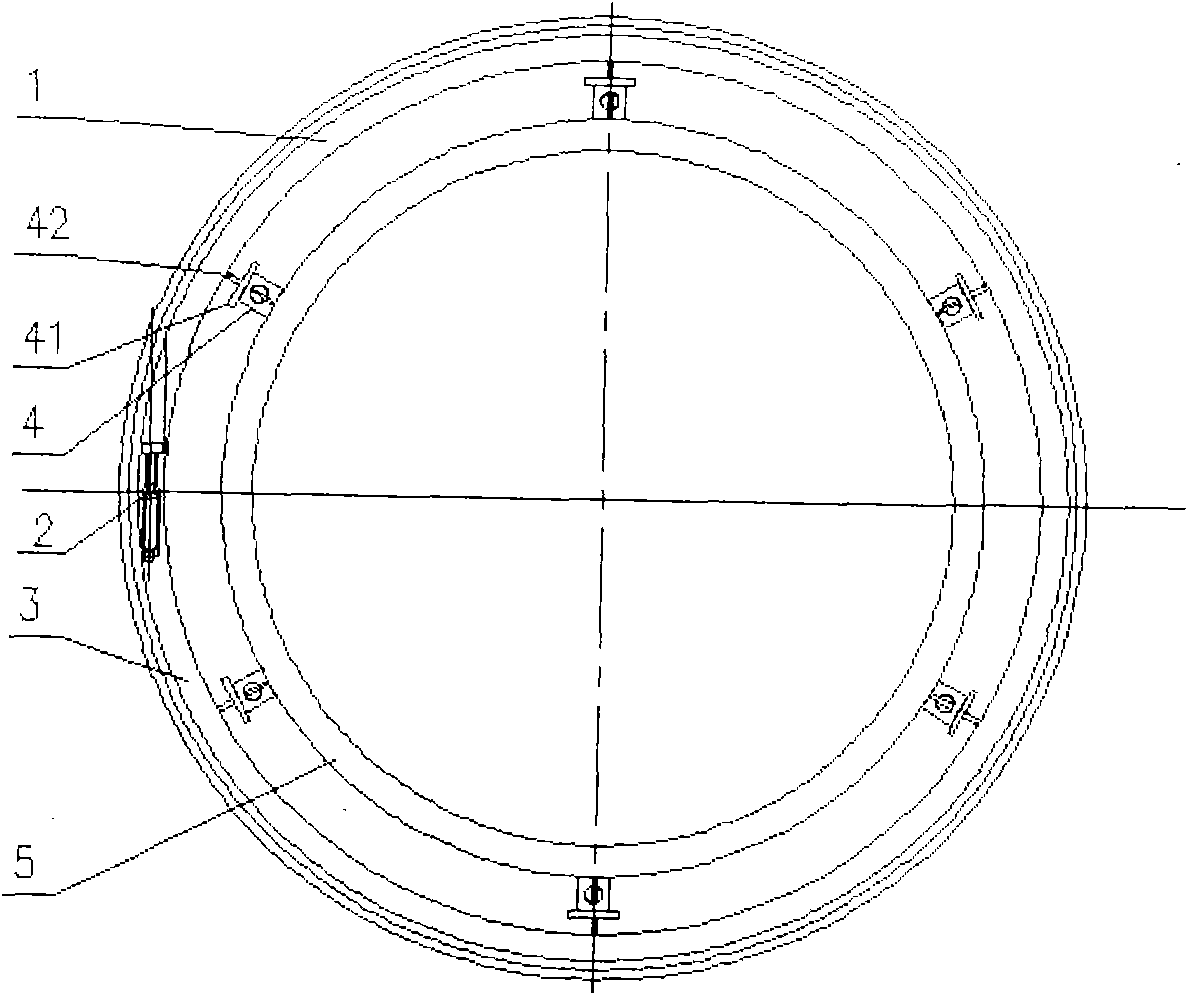

[0020] Such as figure 1 , figure 2 As shown, the running track of the marine steel structure gas shielded welding automatic welding trolley of the present invention is a circular track formed by docking the semicircular upper half track 1 and the lower half track 3; the upper half track 1 and the lower half track The half-tracks 3 are composite guide rails composed of guide rails on both sides of the ring and drive rails between the guide rails on both sides of the ring, and the gap between the drive rail and the guide rails on both sides is set. There are screw holes for screwing and fixing the magnetic support and the track.

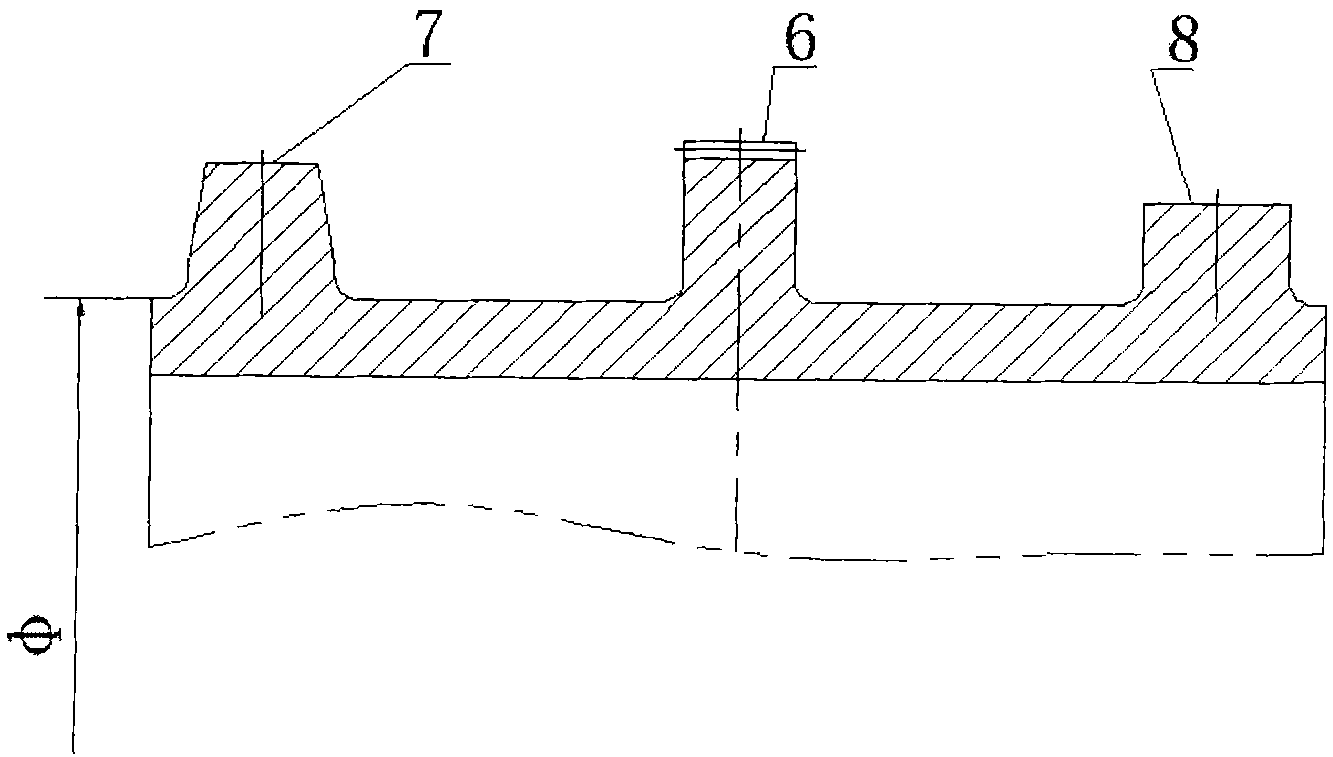

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the running track of the marine steel structure gas shielded welding automatic welding trolley of the present invention, wherein the semicircular upper half track 1 and the lower half track 3 guide rails on one side are guide rails 8 with a square cross section , the guide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com