Universal rotation spherical blender

The technology of a multi-rotating ball type mixer is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc. It can solve problems such as difficult angle adjustment, loud noise, and uneven mixing of materials, so as to save maintenance time and reduce The effect of using cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

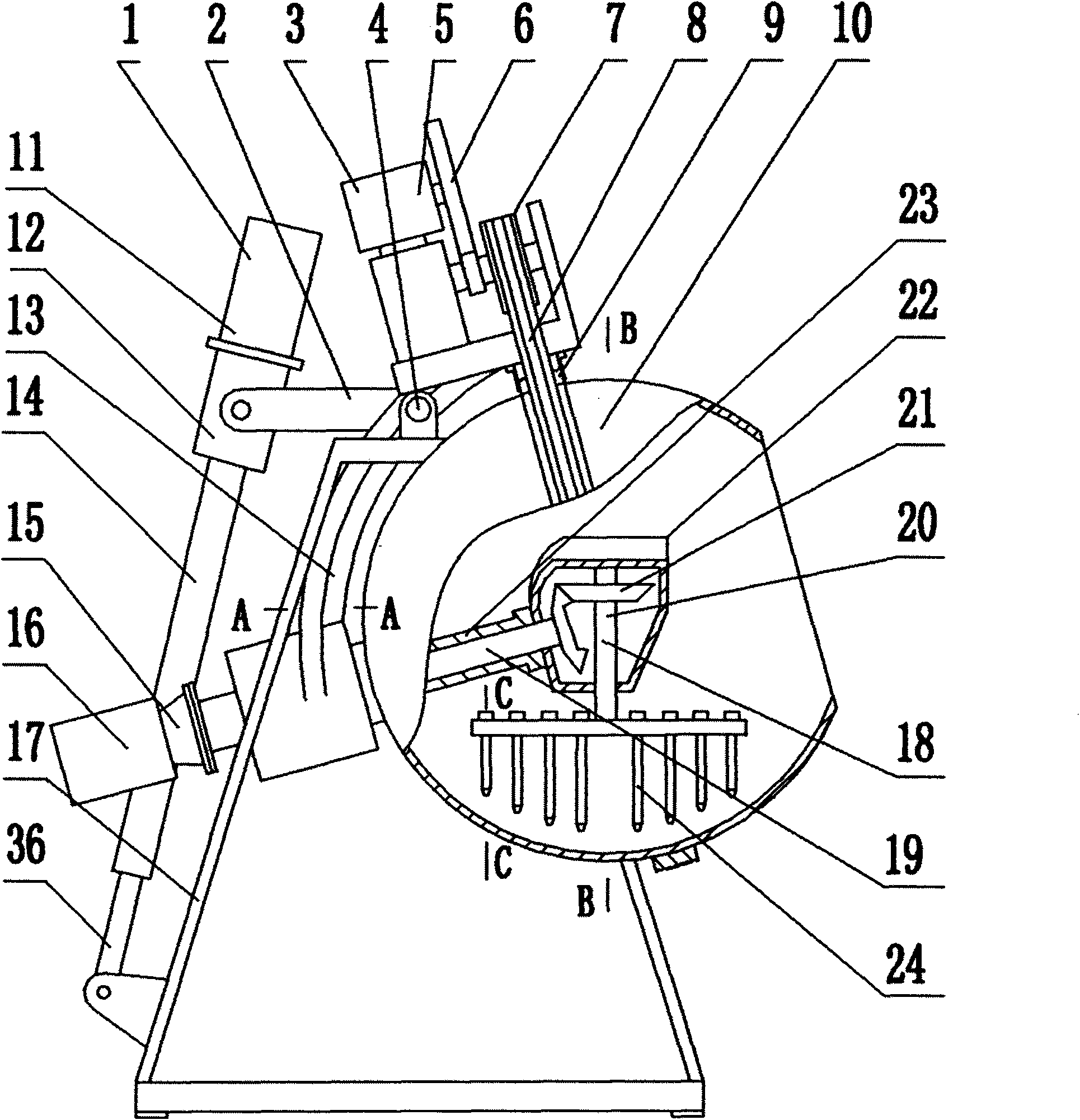

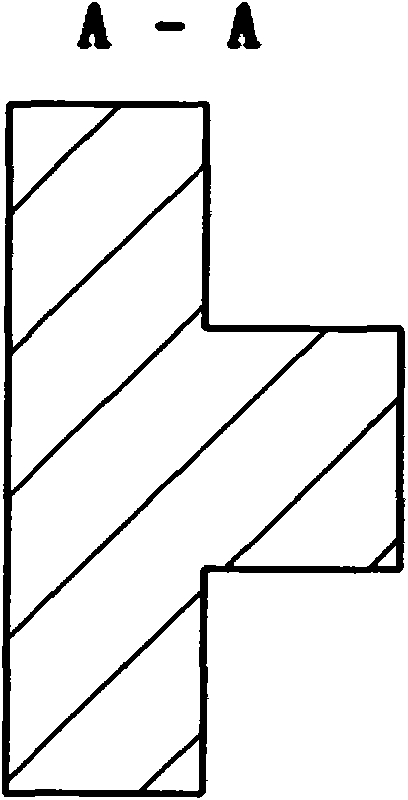

[0017] The present invention comprises machine base 17, support 13, spherical pot body 10, stirring mechanism 18, rotating mechanism 3 and overturning mechanism 1, and support 13 is installed on the machine base 17 by rotating shaft 4, can rotate relative to machine base 17, spherical shape The pot body 10 is fixed on the support 13, and the rotating mechanism 3 includes a rotating motor 5, a transmission gear 6, and a main pulley 7 which are arranged on the support 13 and are connected successively. Pulley 7 and belt 8 from pulley 9.

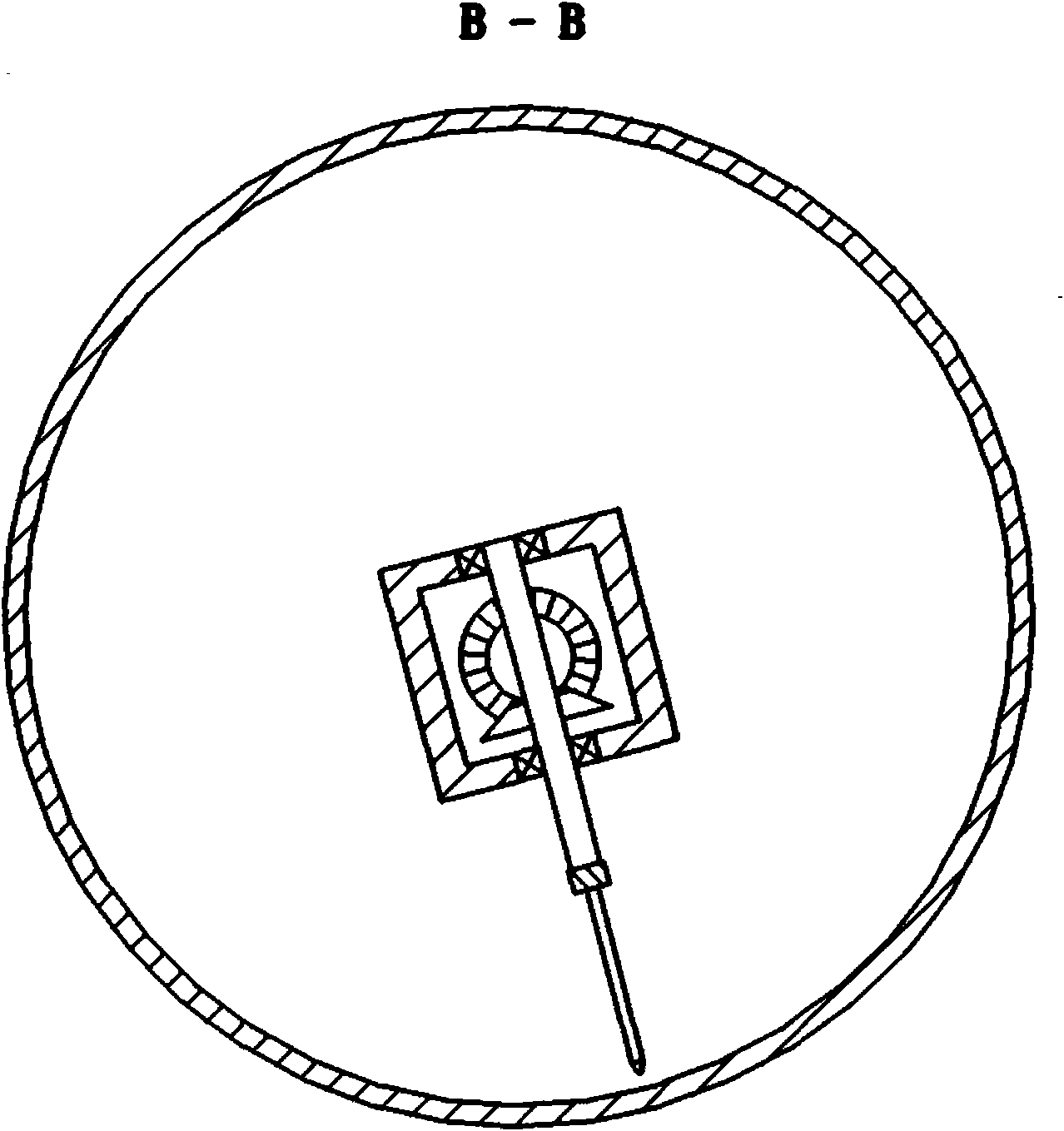

[0018] The stirring mechanism 18 includes a motor 16, a reducer 15, a driving shaft 19, a driven shaft 20 and a stirring fin 24 connected in sequence, and the driving shaft 19 and the driven shaft 20 are meshed and connected by a gear 21; the stirring fin 24 is arranged on the driven shaft 18 The lower end is composed of a beam 25 , a plurality of tines 27 arranged on the beam 25 and a plug 31 , and a spring 29 is arranged in the tines 27 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com