Sackloader

A bag-packing and bag-packing technology, which is applied in the field of bag-packing ship machines, can solve the problems of not being able to give full play to the wharf and ship transshipment capacity, long time for ships to dock at the wharf, and heavy labor for workers, and achieve strong applicable functions, convenient operation, and lighten The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

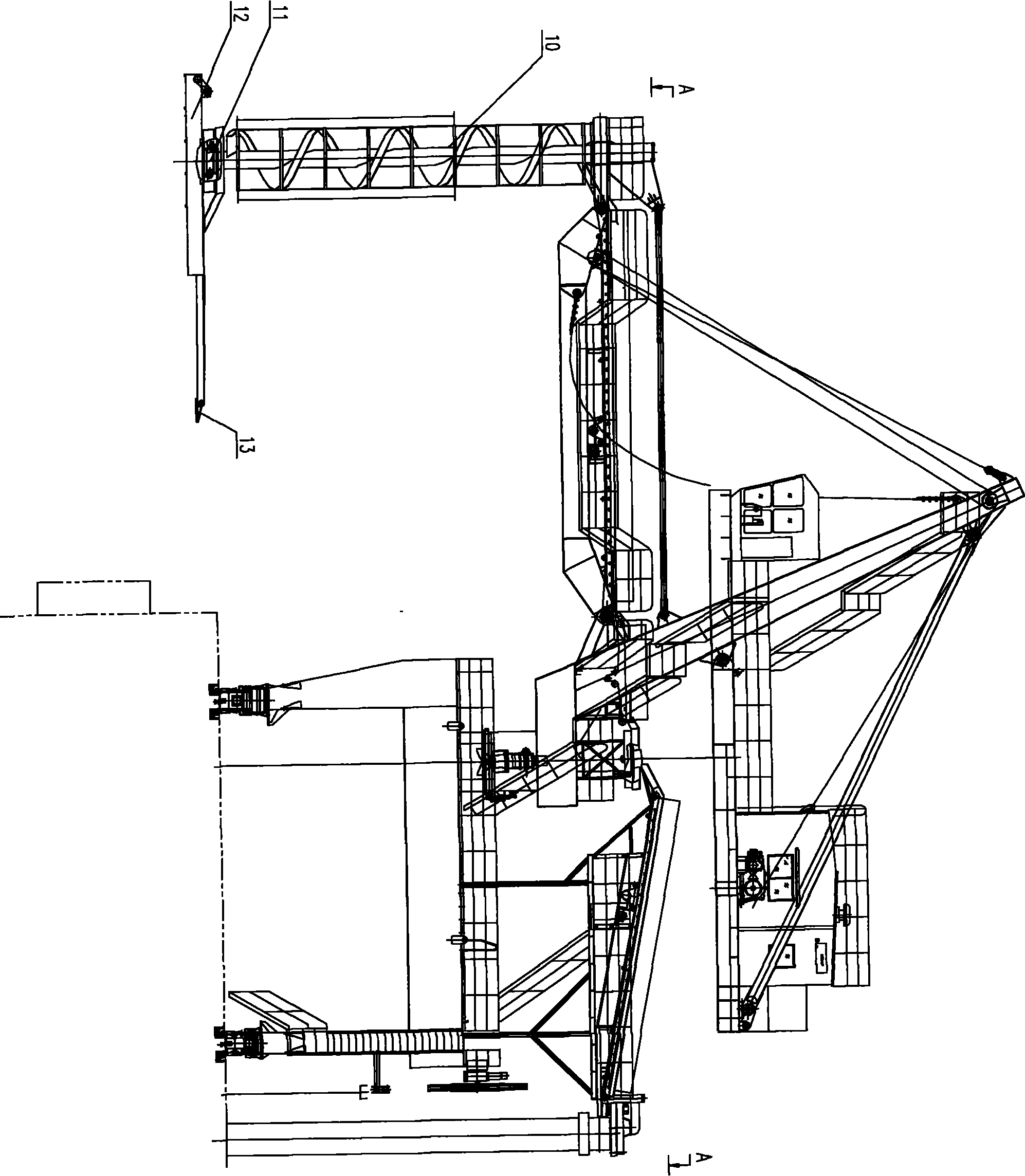

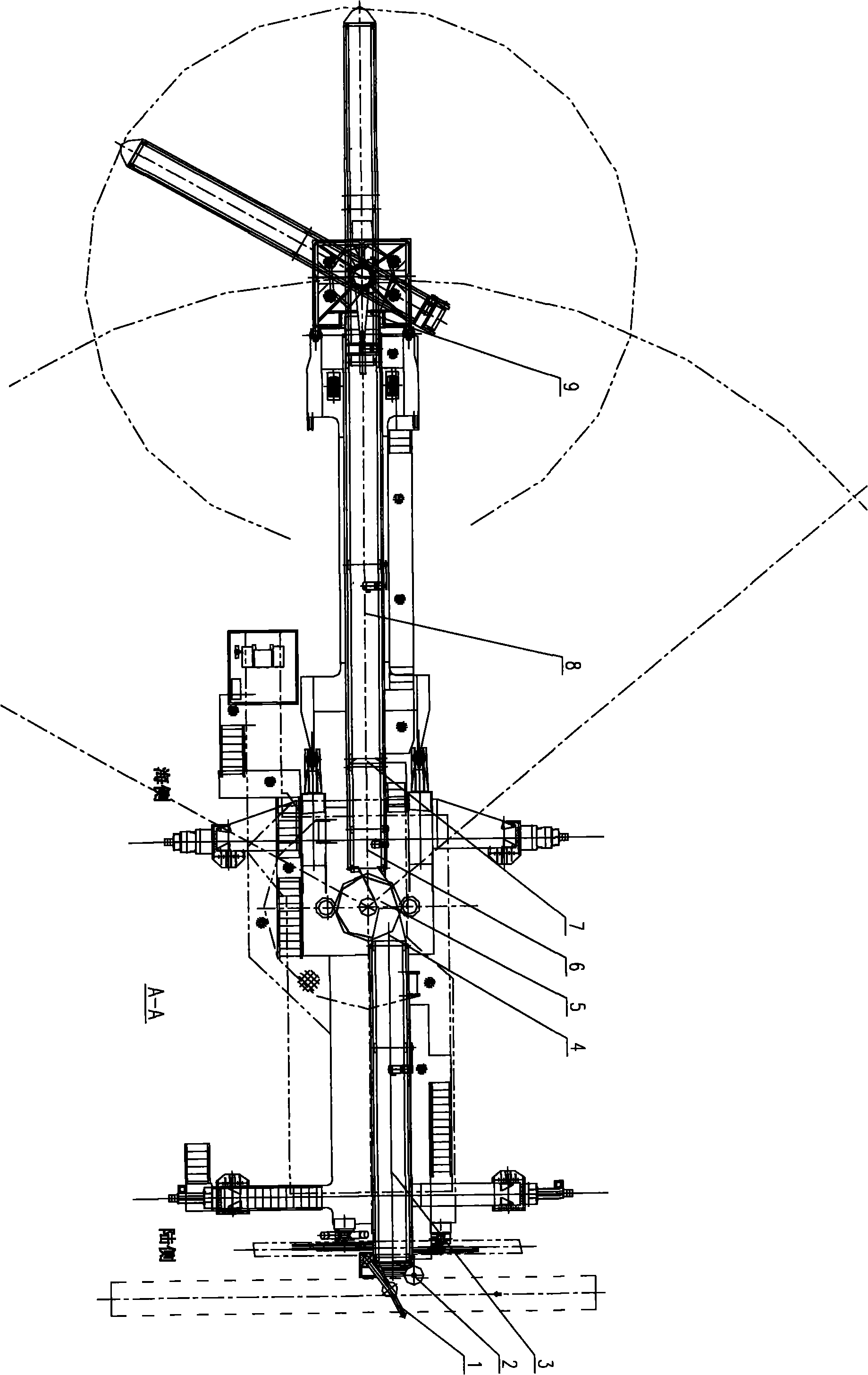

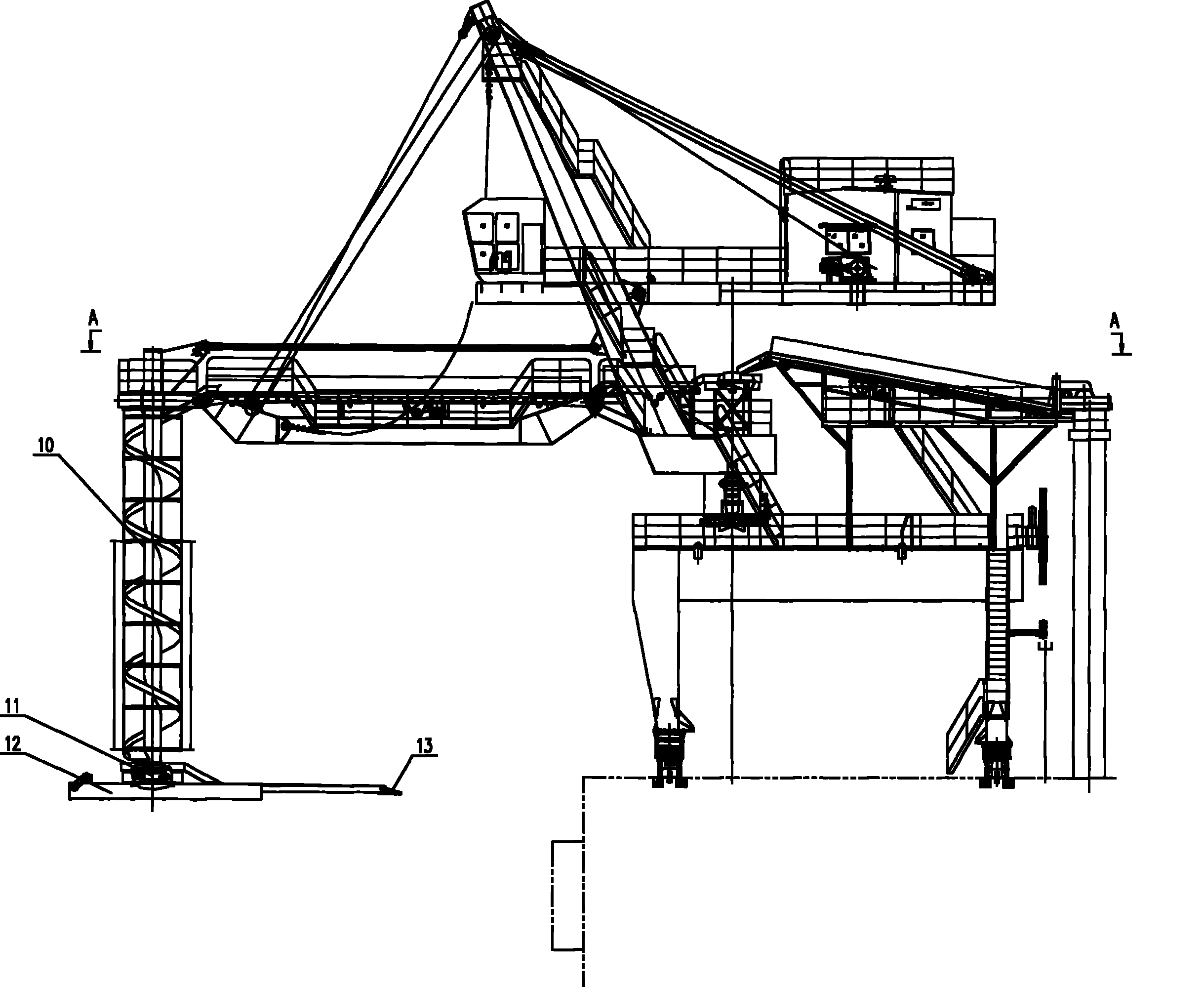

[0027] see figure 1 and figure 2 , The present invention provides a bag packing ship machine, comprising a ship loading machine body, a bag conveying system and a power supply control system.

[0028] The ship body includes a pitching mechanism, a traveling mechanism, a slewing mechanism, an L frame, an arm frame, and a door frame, and has functions such as rotatable, luffing, and walking.

[0029] The bag conveying system is set on the loading body, mainly composed of power baffle 1, rotary guide wheel and idler 2, material receiving belt conveyor 3, slide plate 4, center material receiving disc 5, transition belt conveyor 6, slide plate 7. Boom belt conveyor 8, sliding plate 9, spiral chute 10, lower material receiving disc 11, stacking belt conveyor 12 and duck tongue guide plate 13, etc.

[0030] The power baffle 1 is arranged on the main conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com