Process for producing a polarizing film

A manufacturing method and technology of polarizing film, applied in the direction of optics, optical elements, polarizing elements, etc., can solve problems such as foreign matter defects, wrinkling, foreign matter defects, and film wrinkling that may not be fully suppressed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Dip a polyvinyl alcohol film with a width of 450 mm and a thickness of 75 μm (Cola Li Vinylon VF-PS#7500, a degree of polymerization of 2400, a degree of saponification of 99.9 mol % or more) in pure water at 30°C in a tensioned state so that the film does not relax. 100 seconds to fully swell the membrane.

[0081] Then, uniaxial stretching was carried out while dipping in an aqueous solution of iodine / potassium iodide / water in a weight ratio of 0.02 / 1.5 / 100. Then, immerse in an aqueous solution of potassium iodide / boric acid / water at a weight ratio of 12 / 4.4 / 100 at 55° C., perform boric acid treatment (water resistance treatment), and perform uniaxial stretching until the cumulative stretching ratio relative to the raw material is 5.5 times, after that, dip in an aqueous solution at 40°C with a weight ratio of potassium iodide / boric acid / water of 9 / 2.9 / 100.

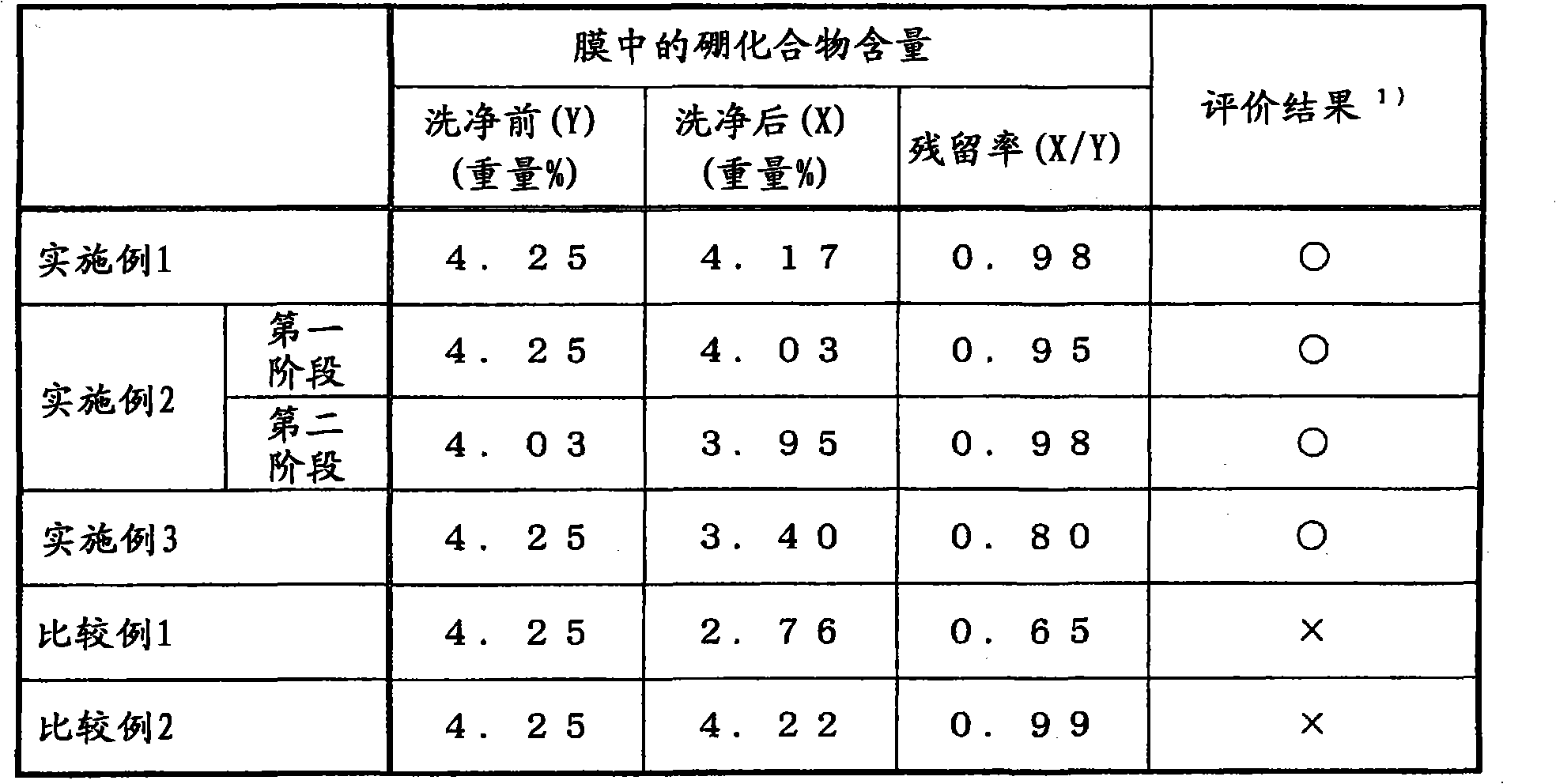

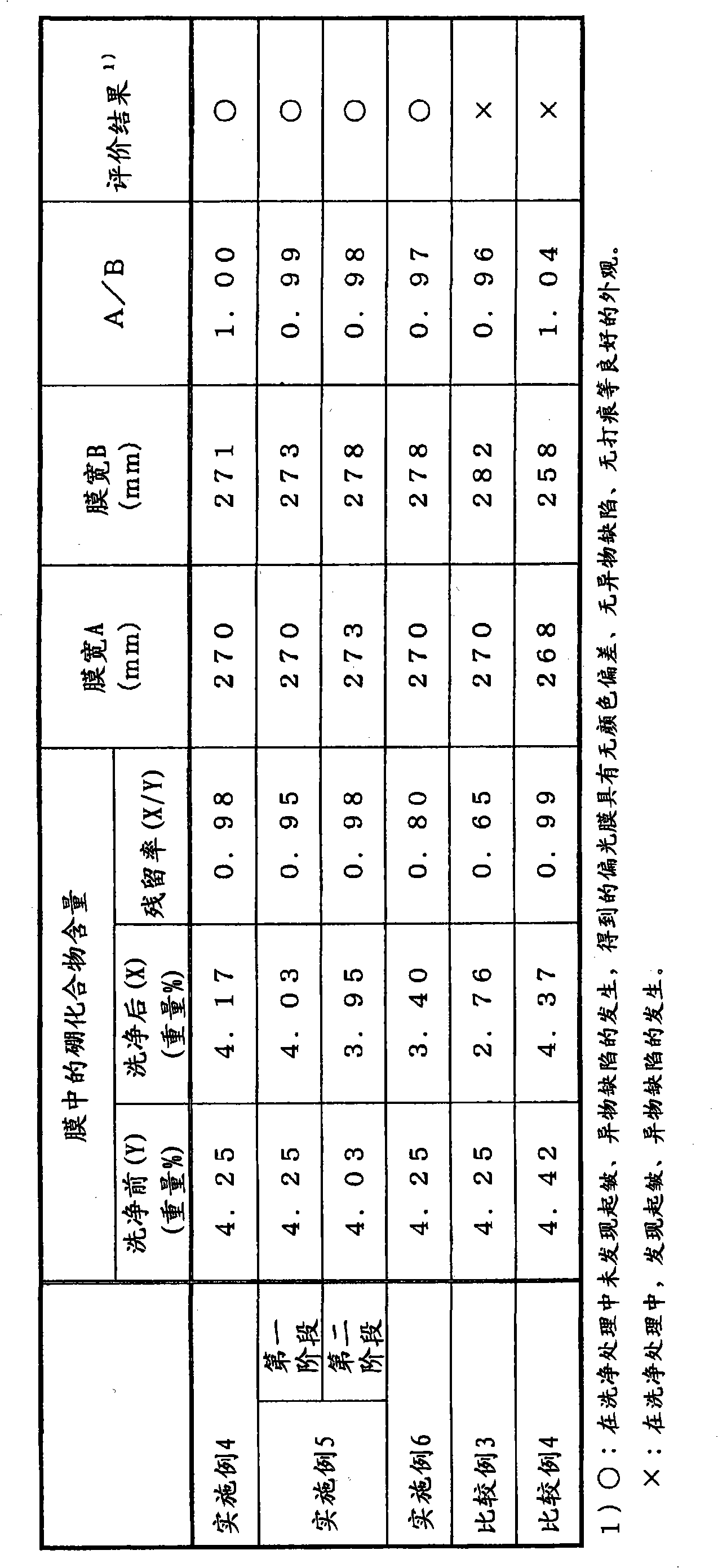

[0082] Then, it was dipped and washed in pure water at 5° C. for 8 seconds. After this washing process, it d...

Embodiment 2

[0084] Set up 2 cleaning tanks. In the first stage, immerse and wash for 8 seconds in an aqueous solution at 15°C with a weight ratio of potassium iodide / boric acid / water of 0.3 / 0.15 / 100; in the second stage, immerse in pure water at 15°C Except washing for 3 seconds, it carried out similarly to the said Example 1, and obtained the polarizing film with a thickness of 28 micrometers.

[0085] At this time, the content of the boron compound in the film before the cleaning treatment in the first stage was 4.25% by weight, and the content of the boron compound in the film after the cleaning treatment was 4.03% by weight. Furthermore, the content of the boron compound in the film before the cleaning treatment in the second stage was 4.03% by weight, and the content of the boron compound in the film after the cleaning treatment was 3.95% by weight. In addition, the residual ratio in the first stage was 0.95, and the residual ratio in the second stage was 0.98, and no wrinkling was f...

Embodiment 3

[0088] A polarizing film with a thickness of 28 μm was obtained in the same manner as in Example 1, except that the potassium iodide / boric acid / water weight ratio was 0.6 / 0.3 / 100 in an aqueous solution at 25° C. and washed for 48 seconds. The content of the boron compound in the film before the cleaning treatment at this time was 4.25% by weight, and the content of the boron compound in the film after the cleaning treatment was 3.40% by weight. In addition, the residual ratio was 0.80, and no wrinkles were observed in the film during the cleaning treatment. Moreover, no foreign matter defect was found to occur, and the obtained polarizing film had good appearance such as no color deviation, no foreign matter defect, and no scratches.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com