Preparation method of polyethylene flexible printing environment-friendly thin film

A polyethylene and film technology, applied in application, coating, ink and other directions, can solve the problems of difficult recycling of packaging bags, a large amount of waste, and difficult to degrade, and achieve the effect of low cost, strong industrial feasibility, and reduction of waste gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

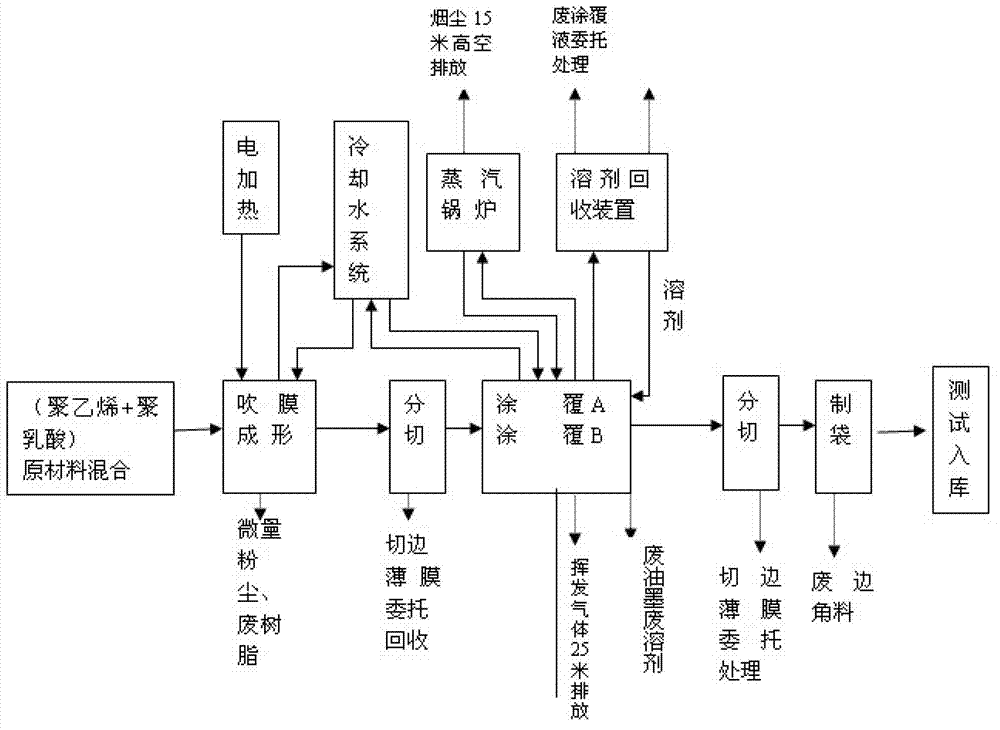

Image

Examples

Embodiment 1

[0021] 1) Mix polyethylene particles and polylactic acid evenly to obtain a mixture;

[0022] 2) Use a film blowing machine to heat and melt the mixture and blow it into a film;

[0023] 3) Use a slitting machine to slit the film;

[0024] 4) Coating the slit film, and the inks and solvents used in the coating process are water-soluble inks and solvents that do not contain toluene. The components of the ink are n-propanol, n-propyl acetate, ethyl Propanol and ethyl acetate, the weight percentages of n-propanol, n-propyl acetate, ethylene-propanol and ethyl acetate are 30% of n-propanol, 10% of n-propyl acetate, 1% of ethylene-propanol, and 1% of ethyl acetate , the composition of solvent has isopropanol, n-propyl acetate and butyl acetate, and the weight percentages of isopropanol, n-propyl acetate and butyl acetate are respectively isopropanol 55%, n-propyl acetate 25%, acetic acid Butyl fat 5%;

[0025] 5) Slitting the coated film;

[0026] 6) Use the bag making machine ...

Embodiment 2

[0029] 1) Mix polyethylene particles and polylactic acid evenly to obtain a mixture;

[0030] 2) Use a film blowing machine to heat and melt the mixture and blow it into a film;

[0031] 3) Use a slitting machine to slit the film;

[0032] 4) Coating the slit film, and the inks and solvents used in the coating process are water-soluble inks and solvents that do not contain toluene. The components of the ink are n-propanol, n-propyl acetate, ethyl Propanol and ethyl acetate, the weight percentages of n-propanol, n-propyl acetate, ethylene-propanol and ethyl acetate are 35% of n-propanol, 15% of n-propyl acetate, 6% of ethylene-propanol, and 5% of ethyl acetate , the composition of the solvent has isopropanol, n-propyl acetate and butyl acetate, and the weight percentages of isopropanol, n-propyl acetate and butyl acetate are respectively 60% of isopropanol, 30% of n-propyl acetate, acetic acid Butyl fat 10%;

[0033] 5) Slitting the coated film;

[0034] 6) Use the bag maki...

Embodiment 3

[0037] 1) Mix polyethylene particles and polylactic acid evenly to obtain a mixture;

[0038] 2) Use a film blowing machine to heat and melt the mixture and blow it into a film;

[0039] 3) Use a slitting machine to slit the film;

[0040] 4) Coating the slit film, and the inks and solvents used in the coating process are water-soluble inks and solvents that do not contain toluene. The components of the ink are n-propanol, n-propyl acetate, ethyl Propanol and ethyl acetate, the weight percentages of n-propanol, n-propyl acetate, ethylene-propanol and ethyl acetate are 40% of n-propanol, 20% of n-propyl acetate, 10% of ethylene-propanol, and 10% of ethyl acetate , the composition of the solvent has isopropanol, n-propyl acetate and butyl acetate, and the weight percentages of isopropanol, n-propyl acetate and butyl acetate are respectively 65% of isopropanol, 35% of n-propyl acetate, acetic acid Butyl fat 15%;

[0041] 5) Slitting the coated film;

[0042] 6) Use the bag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com