Acceleration and deceleration control method for high speed machining of numerical control machine

A technology of acceleration and deceleration control and CNC machine tools, which is applied in the direction of digital control and electrical program control, and can solve the problems of complex implementation and large amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

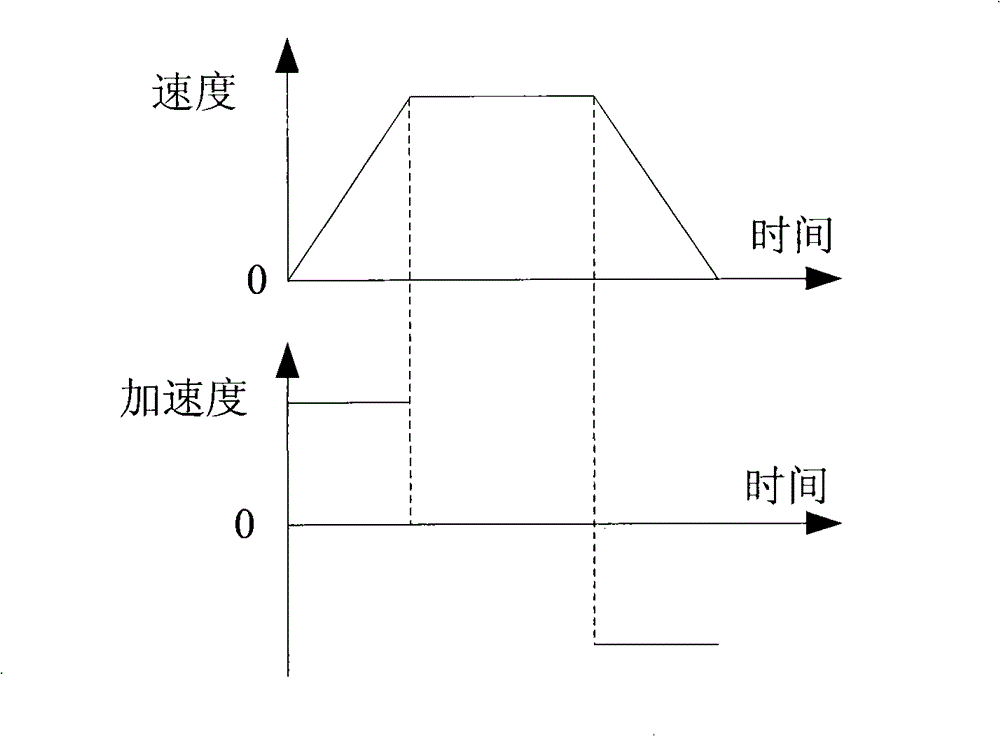

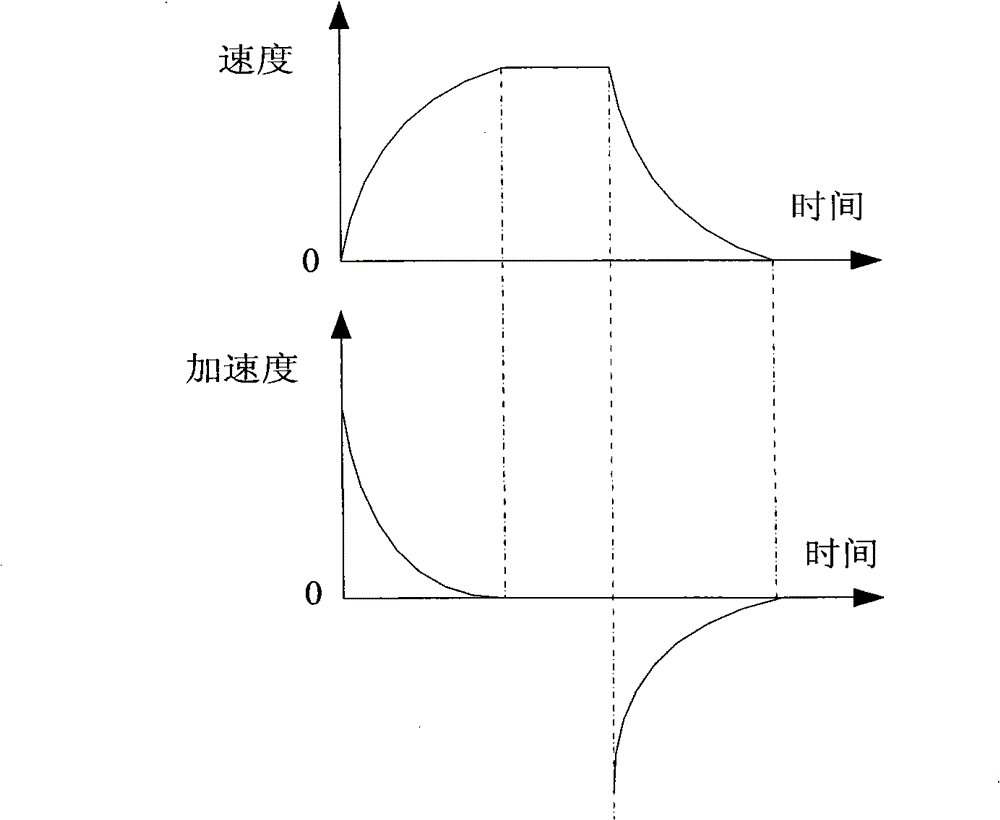

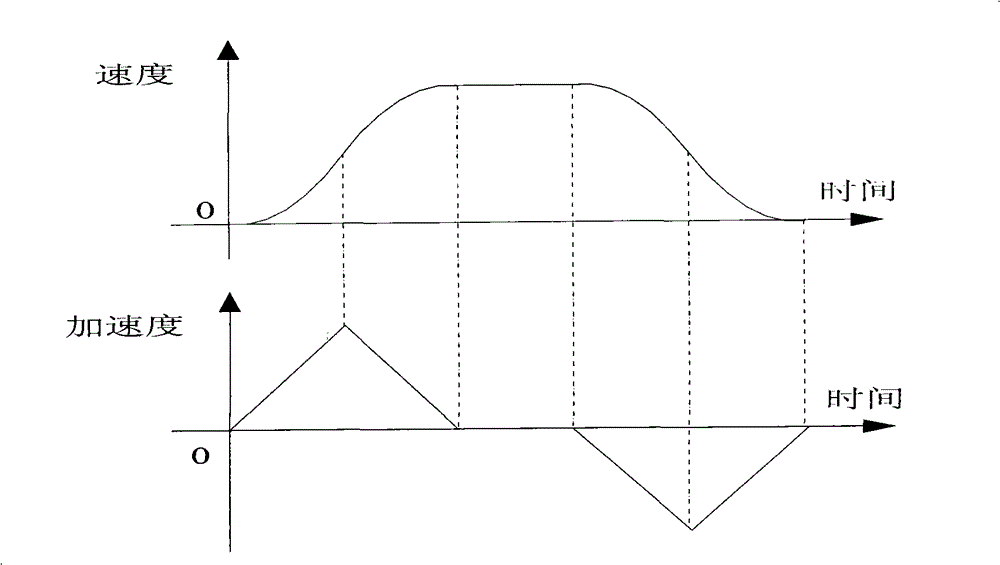

[0061] The method of the present invention is based on the discrete sampling model, combined with the moving average filter technology, on the basis of analyzing the acceleration and deceleration control method of the cubic polynomial S-curve, and proposes an acceleration and deceleration control method that can ensure that the speed, acceleration and jerk are all continuous, and from the theory and The performance of the method of the present invention is demonstrated in practice in two aspects.

[0062] Such as Figure 4-5 Shown, the inventive method comprises the following steps:

[0063] Acceleration and deceleration control parameter initialization;

[0064] Calculate the total length of the current motion segment to be planned;

[0065] Judging whether to modify the feedrate of the current motion segment;

[0066] If no trimming operation is performed, it is judged whether it is the first time to control the acceleration and deceleration of the movement segment;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com