Instruction car control system and instruction car

A technology for control systems and coaching vehicles, applied in educational appliances, transportation and packaging, instruments, etc., can solve problems such as damage to overall strength, inability to distribute torque and bending moment evenly among multiple metal core wires, and cable breakage. The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

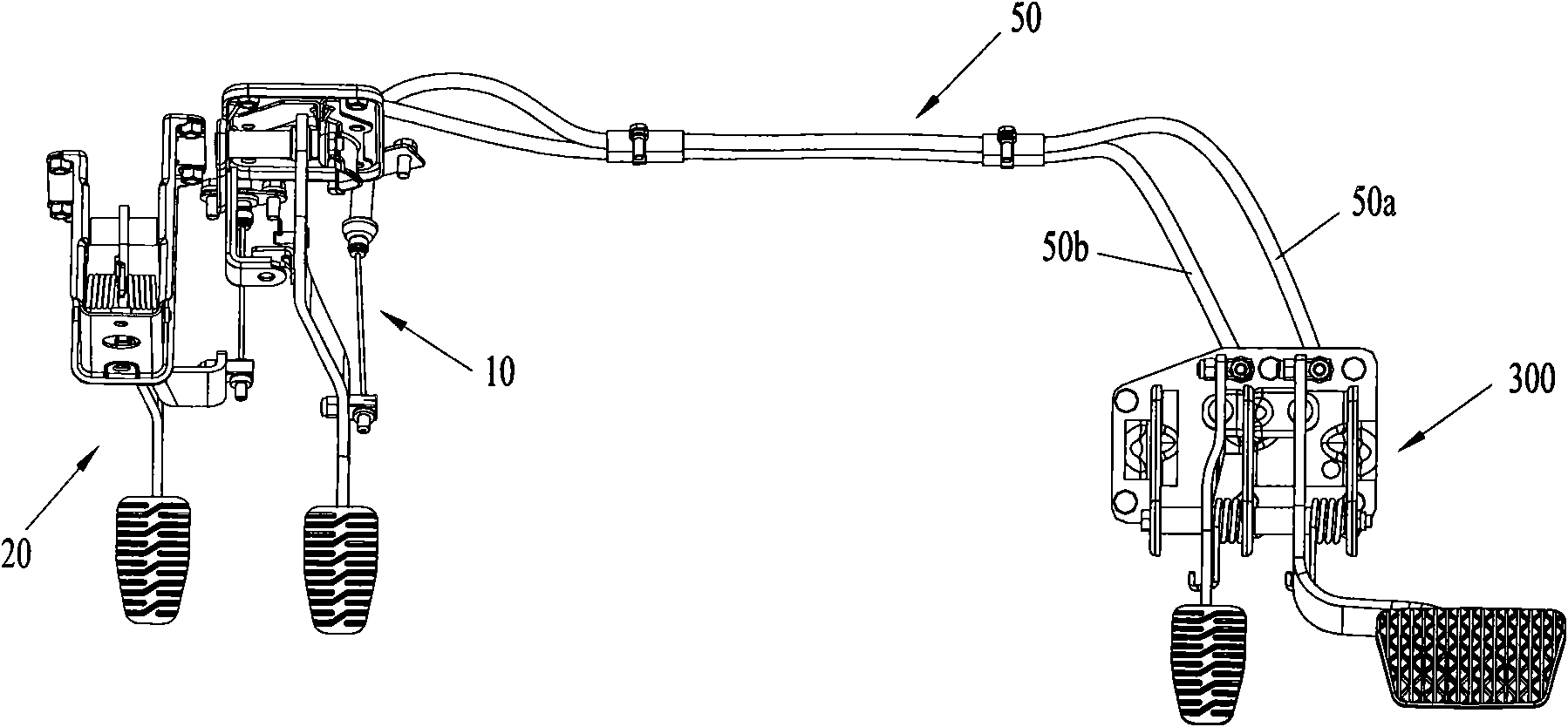

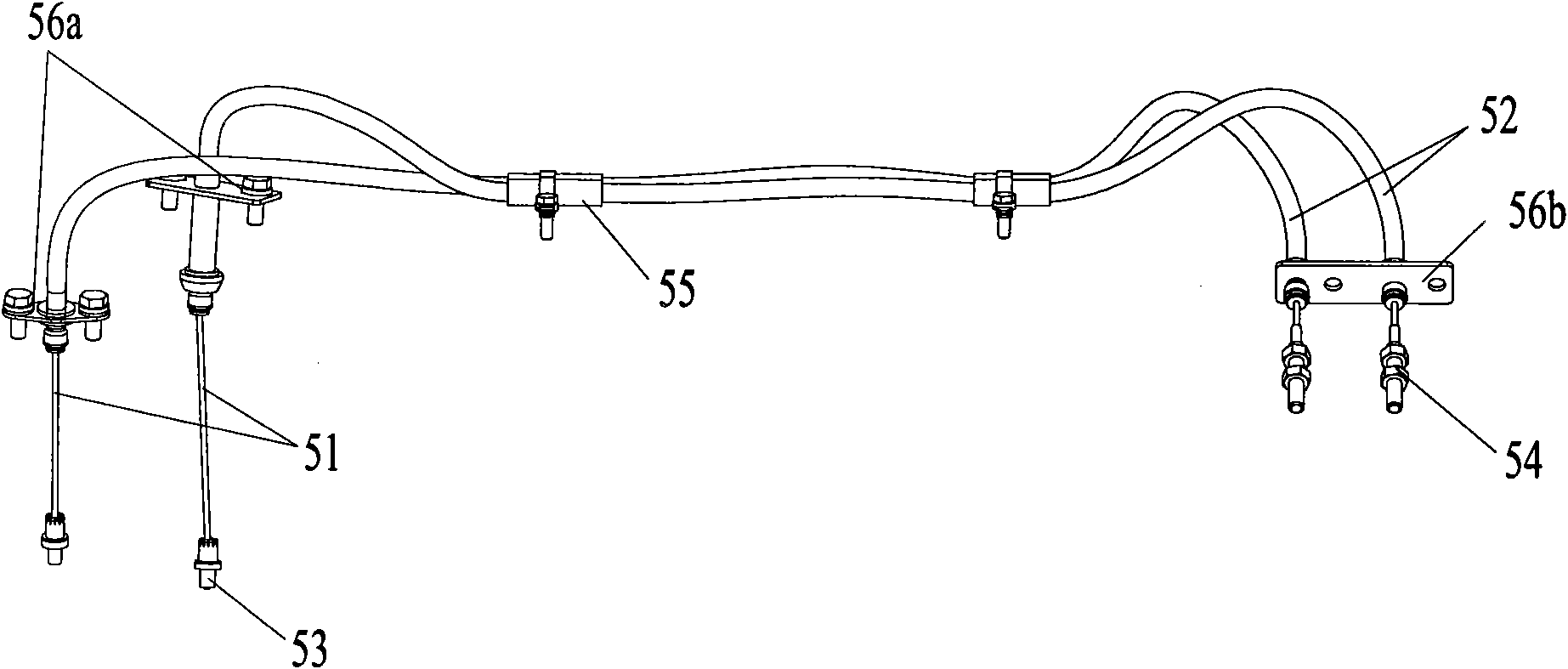

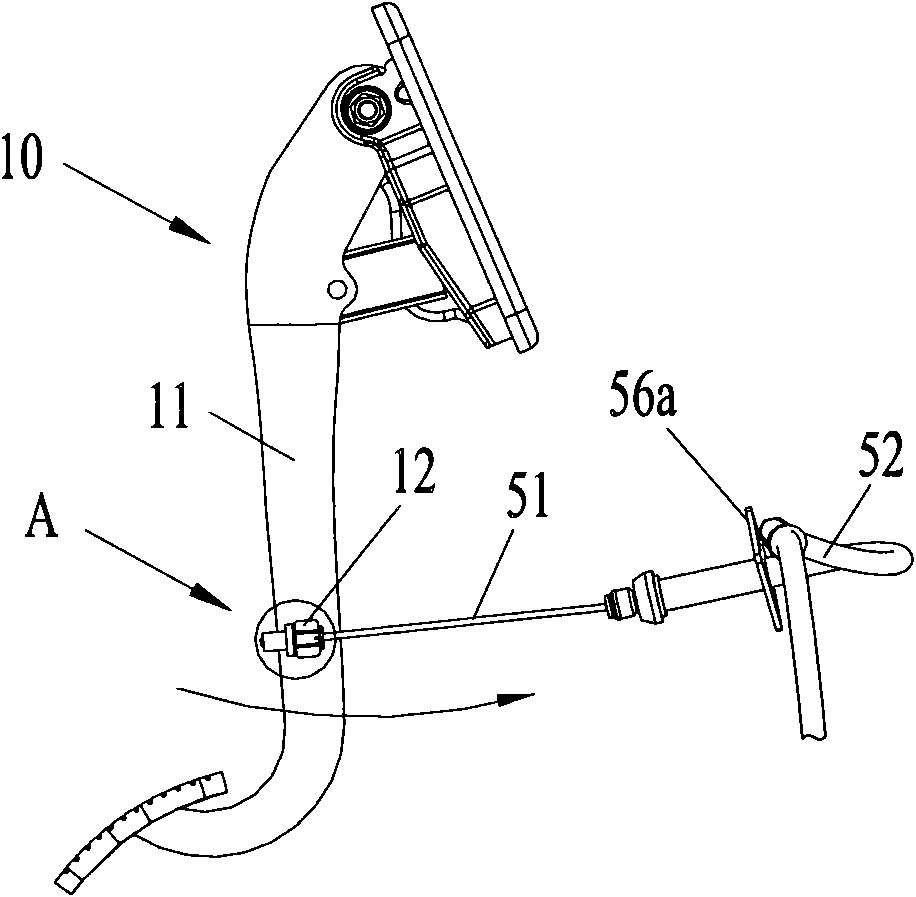

[0019] This coach vehicle control system of the present invention comprises main pedal mechanism and auxiliary pedal mechanism, and described main pedal mechanism and described auxiliary pedal mechanism have main pedal arm and auxiliary pedal arm respectively, and described main pedal arm and described auxiliary pedal arm pass through Cable 50 is connected. Wherein, the main pedal mechanism includes a main pedal planetary shaft rotatably installed on the main pedal arm, the rotation axis of the main pedal planetary shaft is parallel to the pivot axis of the main pedal arm; the auxiliary pedal The mechanism includes an auxiliary pedal planetary shaft rotatably mounted on the auxiliary pedal arm, the rotation axis of the auxiliary pedal planetary shaft is parallel to the pivot axis of the auxiliary pedal arm; the two ends of the cable 50 are respectively connected to to the primary pedal planetary shaft and the secondary pedal planetary shaft.

[0020] Wherein, the main pedal m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com