Belt wheel load removing device for impact sand production machine

A technology of unloading device and sand making machine, applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., can solve problems such as increasing cost, accelerating spindle loss, dislocation, etc., and achieves the effect of reducing loss and bending moment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

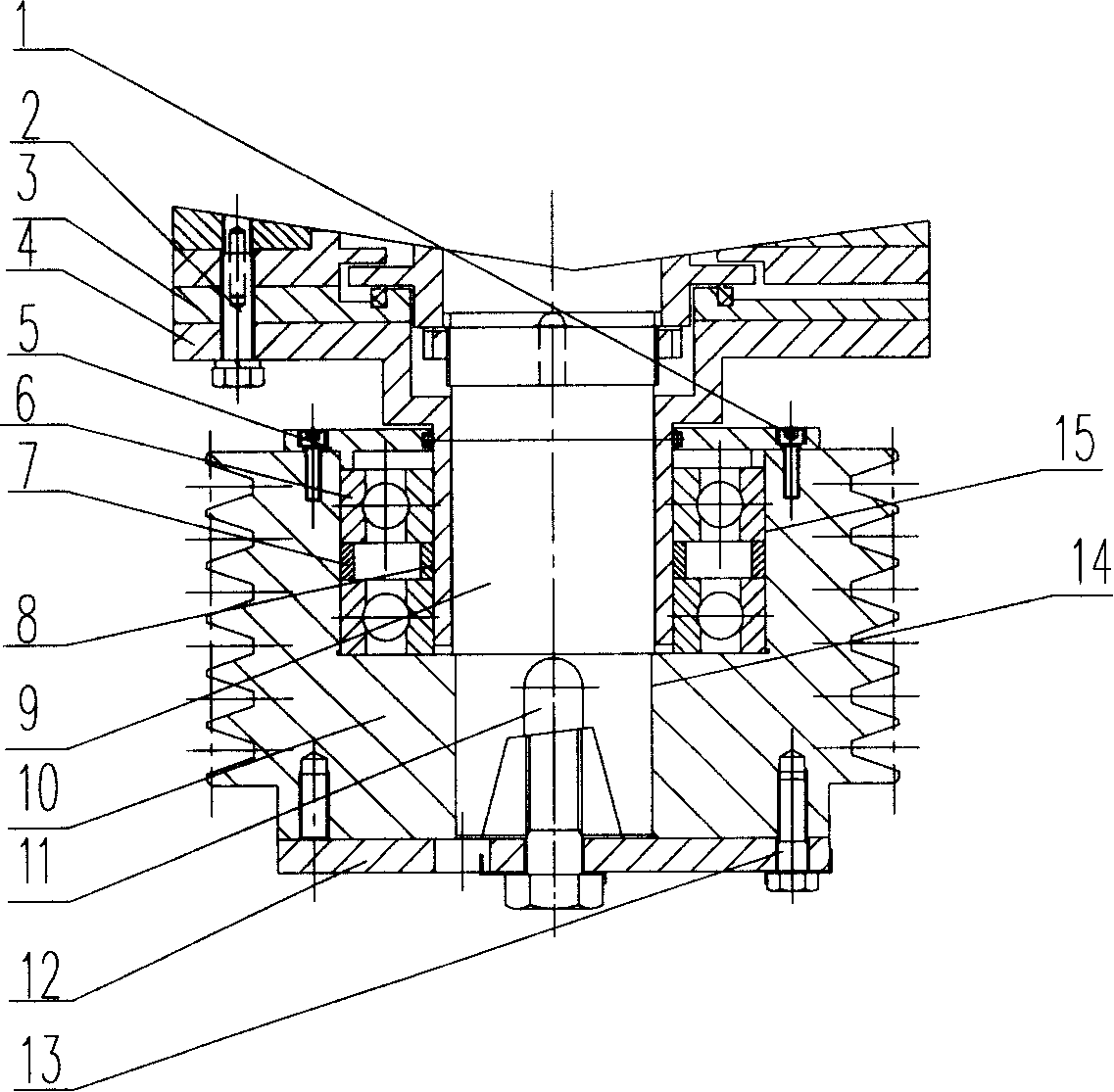

[0008] Such as figure 1 As shown, it is a structural schematic diagram of the pulley unloading device of the present invention. First of all, the difference between the pulley 10 of the present invention and the existing pulley is that it has at least two axial bores 14, 15 that are coaxial but have different inner diameters, and the end near the bearing seat 3 has a larger inner diameter. The axial inner hole 15 of the shaft, the other end is sleeved on the main shaft 9 through the key 11 or the tension sleeve, and the pressure plate 12 is pressed outside the key 11, and the pressure plate 12 is fastened on the pulley 10 with bolts 13, and the pulley is unloaded. The unloading sleeve 4 of the device is empty on the main shaft 9, one end of the unloading sleeve 4 is fixed on the bearing seat 3, and the other end is located in the axial inner hole 15 and connected with the pulley 10 through the bearing 6.

[0009] The connection structure between the bearing 6 and the pulley 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com