Battery steel shell and insulating method and battery thereof

A battery steel shell and battery cell technology, applied in the battery steel shell and its insulation method and the field of batteries, can solve problems such as battery performance deterioration, and achieve the effects of improving performance and capacity, preventing danger, and improving safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

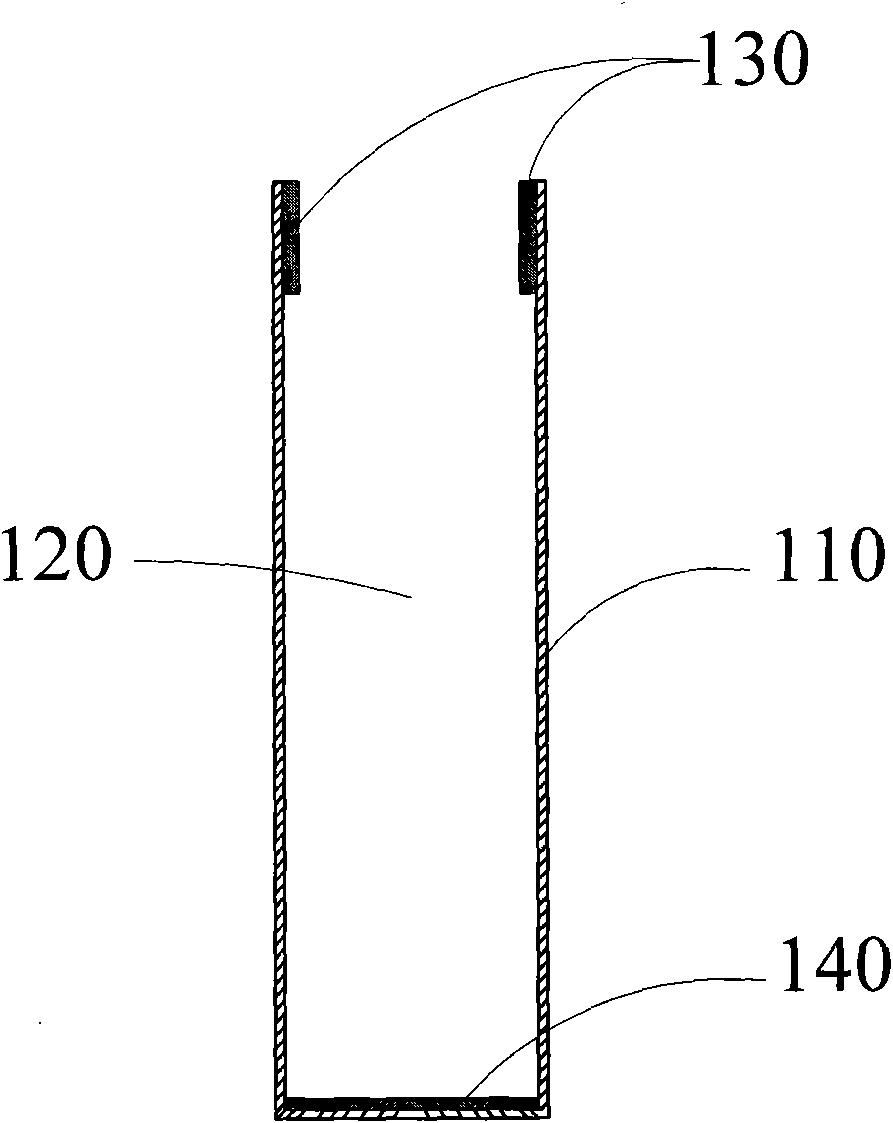

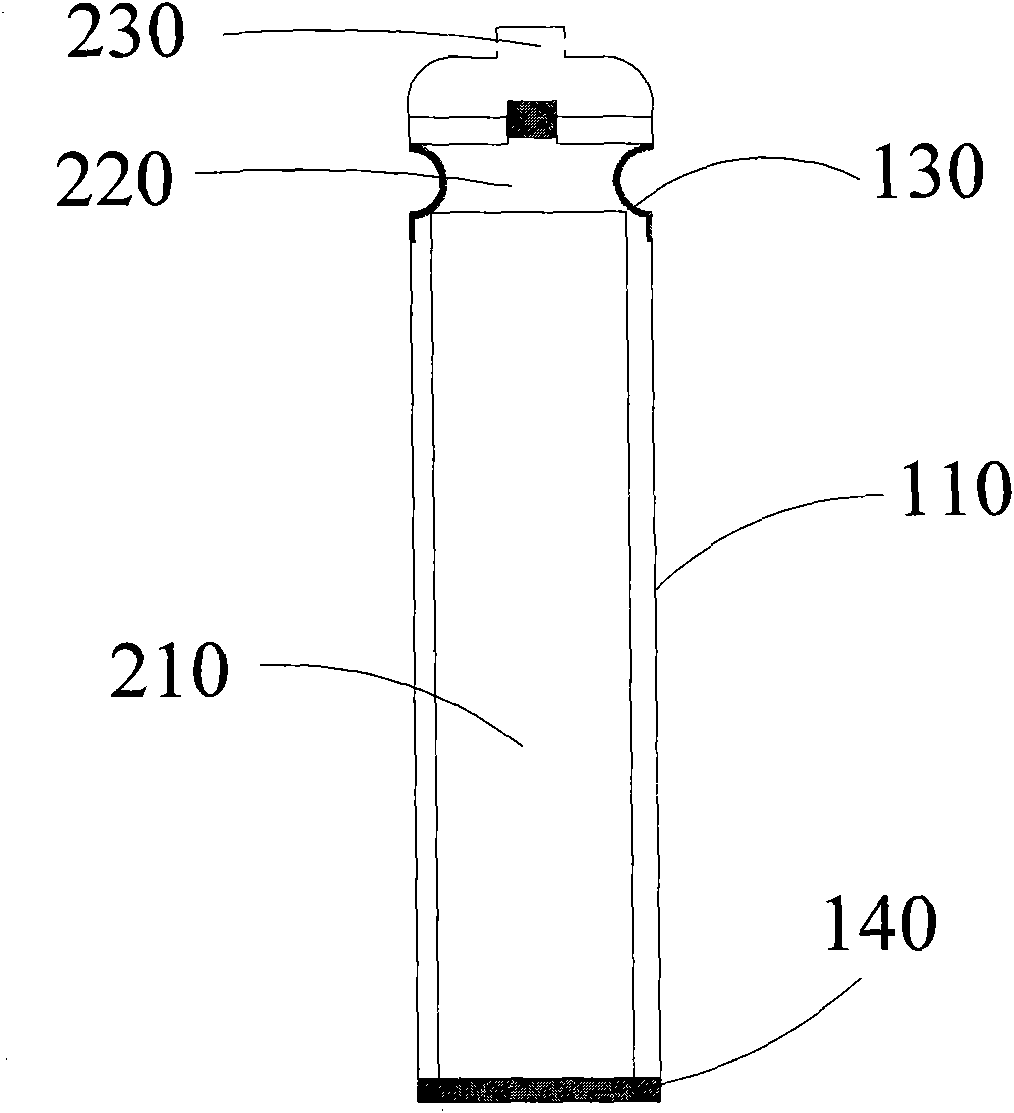

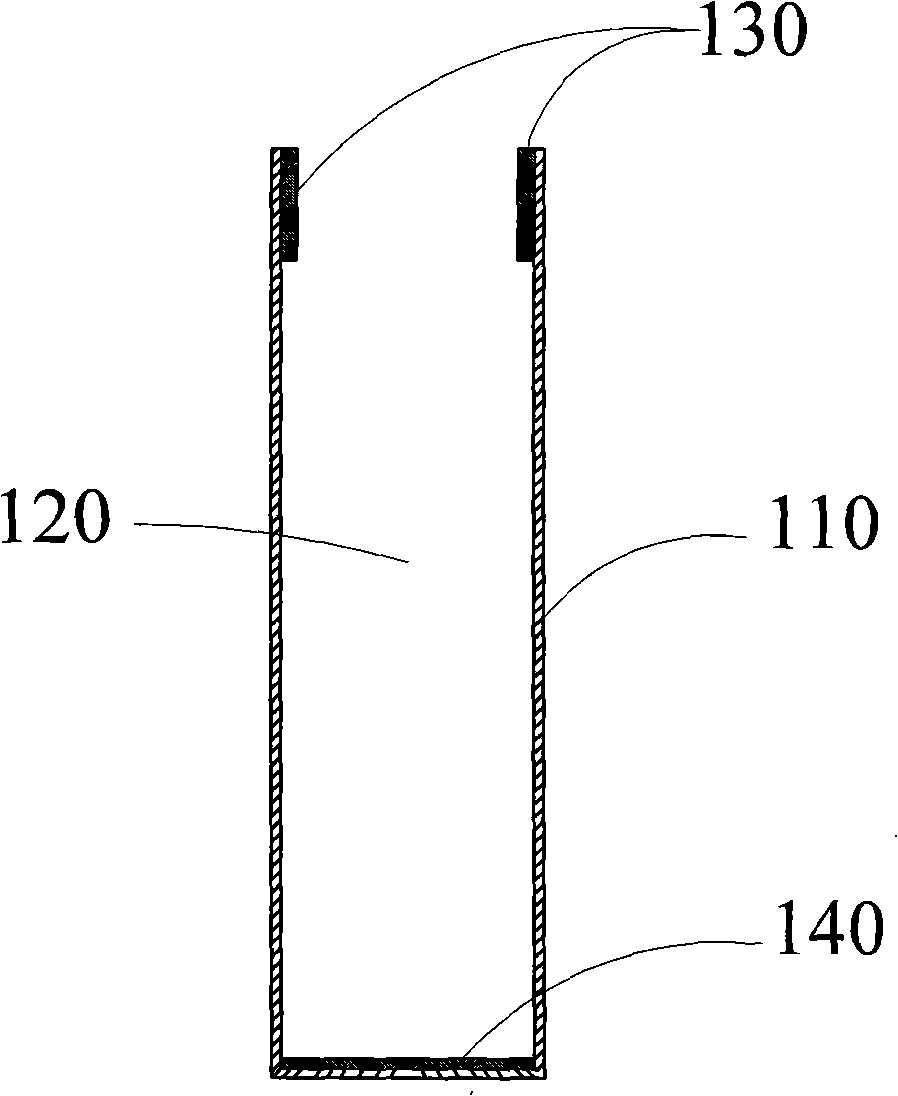

[0021] figure 1 It is a schematic diagram of the battery steel shell structure in an embodiment. figure 2 Is used in an embodiment figure 1 The battery structure diagram of the battery steel case shown.

[0022] Combine figure 1 with figure 2 The battery steel shell includes a shell 110, an inner cavity 120 of the shell, an upper insulating layer 130 and a lower insulating layer 140.

[0023] The internal space of the housing cavity 120 is adapted to the size of the battery core 210 for placing the battery core 210. The upper insulating layer 130 is located on the top inner wall of the casing 110 and surrounds the inner wall of the casing 110 to isolate the upper part of the cell 210 from the casing 110 and insulate the two. The lower insulating layer 140 is located on the inner wall of the bottom of the casing 110 and covers the bottom of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com