Bi-directional tubular type induction motor for home-automation

An induction motor, dual-rotation technology, applied in asynchronous induction motors, electric components, electrical components, etc., can solve problems such as minor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

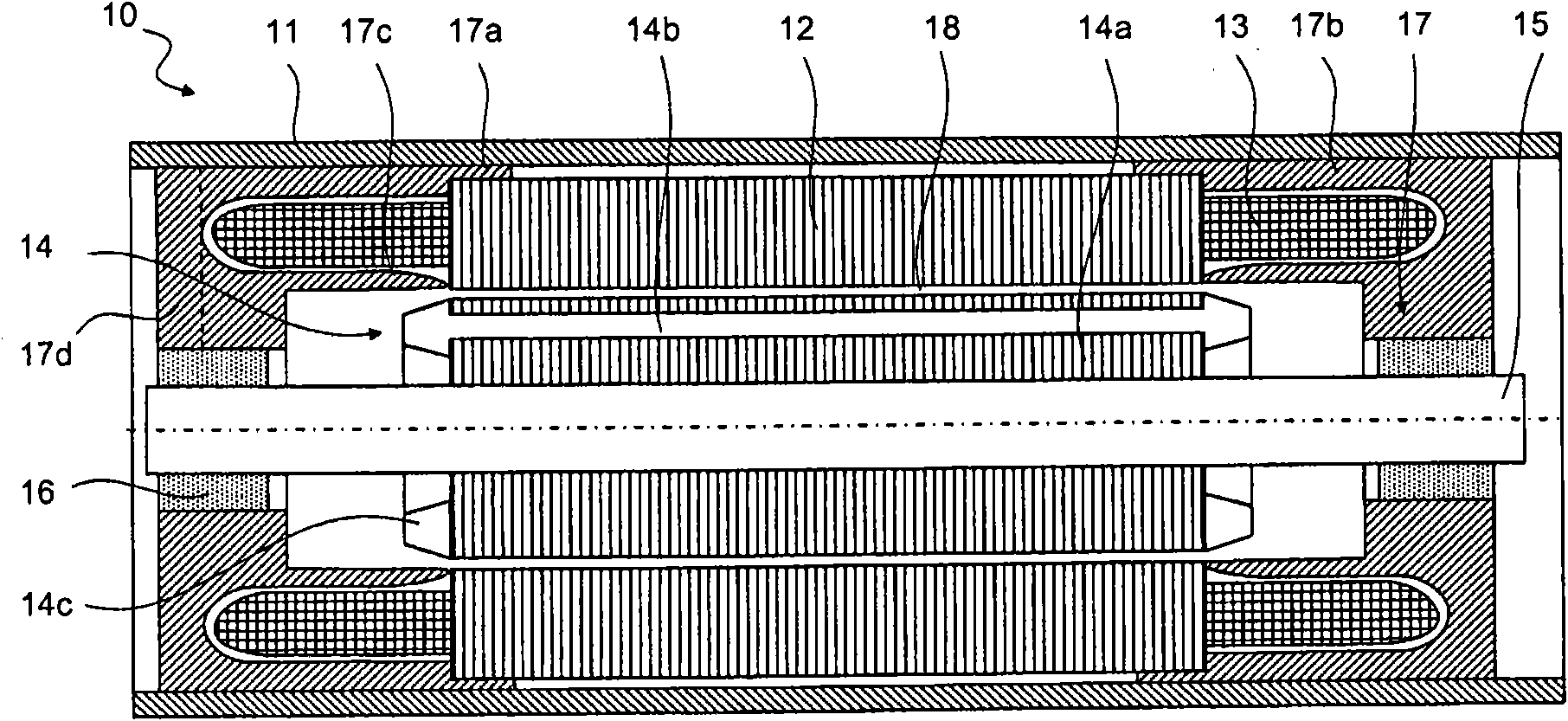

[0040] figure 1represents a longitudinal section of a tubular electric machine 10 according to the prior art. The tubular motor is inserted into an outer tube 11 which extends on both sides of the motor and is shown in cutaway form. The outer tube 11 is the tube of a tubular actuator designed to be installed in a building and comprising at least one mechanical reduction gear (not shown). The electric machine comprises a stator metal lamination stack 12 comprising teeth, not visible in this cross-sectional view, into which windings of enamelled copper wire are inserted. On the outside of the stator, turns of the coil pass from one tooth to the almost diametrically opposite other tooth, forming winding ends 13 or end windings. Depending on the kind of winding method used, "flyer" winding or conventional insertion winding, the winding ends are more or less bulky. The electric machine includes a rotor 14 attached to a shaft 15 . The rotor comprises a stack 14a of rotor metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com