Organic EL device, EL display panel, method for manufacturing the organic EL device and method for manufacturing the EL display panel

A technology for electroluminescent devices and manufacturing methods, applied in the fields of organic light-emitting device manufacturing/processing, organic light-emitting devices, electroluminescent light sources, etc., capable of solving problems such as rising surface impedance, short-circuiting of organic EL devices, and rising driving voltage of organic EL devices, etc. problems, achieve the effects of reducing surface impedance, high luminous efficiency, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0148] In Embodiment 1, a top emission type organic EL device will be described.

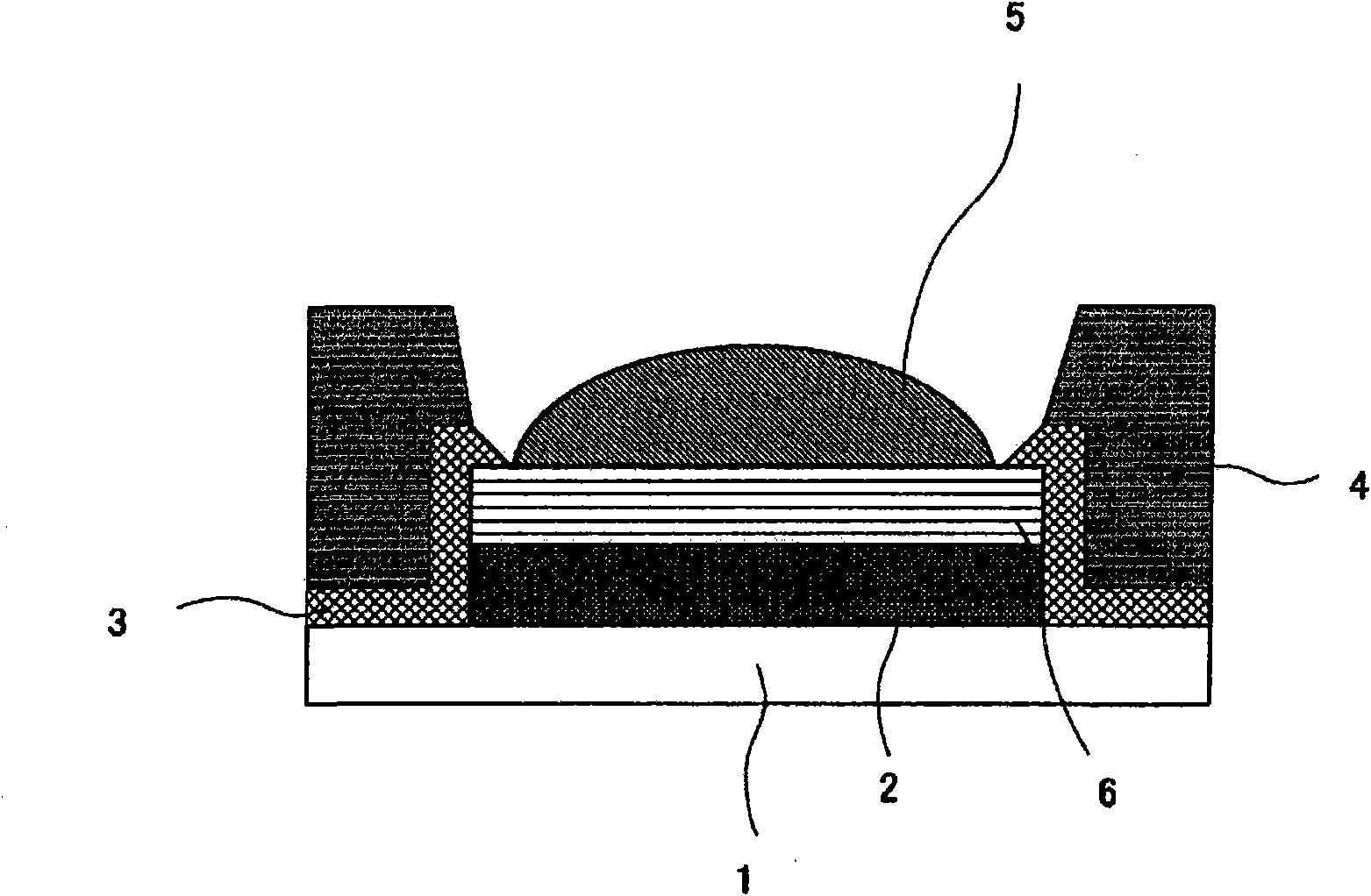

[0149] Figure 5 It is a cross-sectional view of the organic EL device 10 according to Embodiment 1 of the present invention.

[0150] Figure 5 The organic EL device 10 includes: a substrate 100 , a reflective anode 210 , a hole transport layer 510 , an intermediate layer 520 , an organic light-emitting layer 600 , an inorganic film 300 , a bank 400 , a transparent cathode 220 and a sealing film 700 .

[0151] The substrate 100 is, for example, a glass plate.

[0152] The reflective anode 210 is a conductive layer disposed on the substrate 100 . Reflective anode 210 is made of, for example, APC alloy. The reflective anode 210 preferably has a thickness of 100 nm to 200 nm.

[0153] The hole transport layer 510 is disposed on the reflective anode 210 . The hole transport layer 510 is made of tungsten oxide (WOx). The thickness of the hole transport layer 510 is preferably 20 nm to 50 nm. ...

Embodiment approach 2

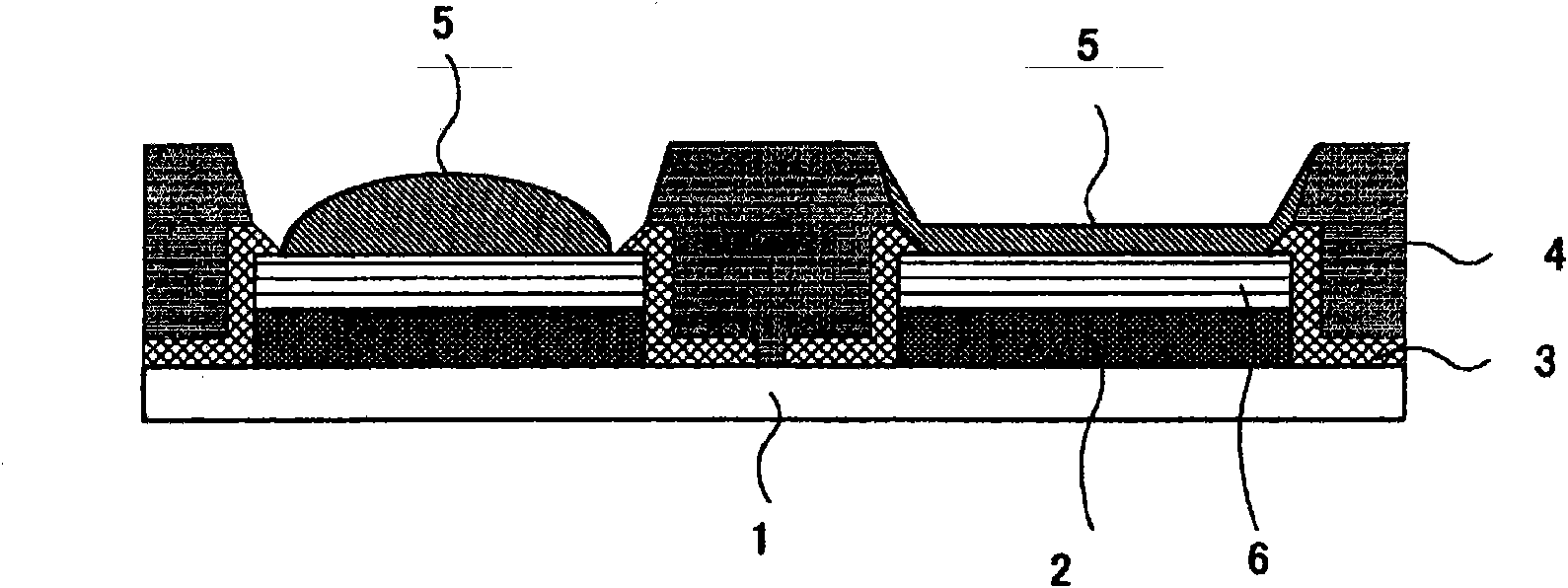

[0174] In Embodiment 1, an organic EL device in which a hole transport layer is in contact with an inorganic film is described. On the other hand, in Embodiment Mode 2, an organic EL device in which a hole transport layer and an inorganic film are separated will be described.

[0175] Figure 7 It is a cross-sectional view of the organic EL device 20 of the second embodiment. exist Figure 7 Among them, the organic EL device 20 includes: a substrate 100, a reflective anode 210, a hole transport layer 510, an intermediate layer 520, an organic light emitting layer 600, an electron transport layer 530, a transparent cathode 220, a sealing film 700, a bank 400, and an inorganic film 300 .

[0176] The materials of the substrate 100, the reflective anode 210, the inorganic film 300, the hole transport layer 510, the intermediate layer 520, the organic light-emitting layer 600, the transparent cathode 220, the sealing film 700, and the banks 400 may be the same as those describe...

Embodiment approach 3

[0182] As described in Embodiment Mode 1 and Embodiment Mode 2, the hole transport layer of the present invention is preferably an oxide of a transition metal, but the material of the hole transport layer of the present invention may also be PEDOT-PSS (doped with Polyethylenedioxythiophene of polystyrene sulfonic acid) When the material of the hole transport layer is PEDOT-PSS, the present invention can protect the surface of the anode from being polluted by the residue of the bank.

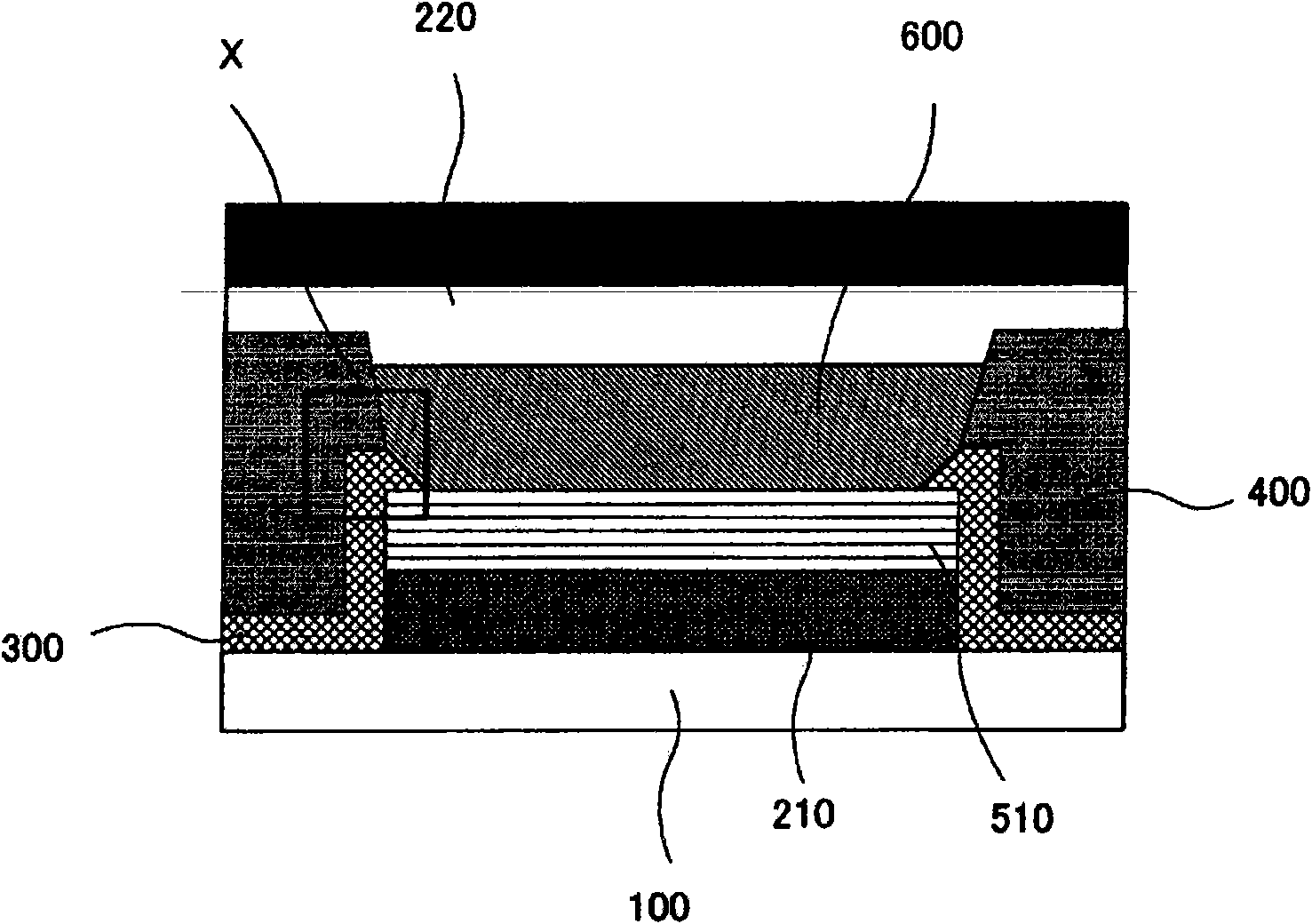

[0183] In Embodiment 3, an example in which the material of the hole transport layer is PEDOT-PSS (polyethylenedioxythiophene doped with polystyrenesulfonic acid) will be described. Figure 9 It is a cross-sectional view of the organic EL device 30 according to Embodiment 3 of the present invention.

[0184] Figure 9 The organic EL device 30 includes: a substrate 100 , a transparent anode 210 , a hole transport layer 510 , an intermediate layer 520 , an organic light-emitting layer 600 , an ino...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap