Modular type linear motor armature, modular type linear motor having the armature, and conveyor apparatus

A linear motor, modular technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of product cost, customer product price, delivery time impact, etc., and achieve the effect of shortening operation time, ensuring performance, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

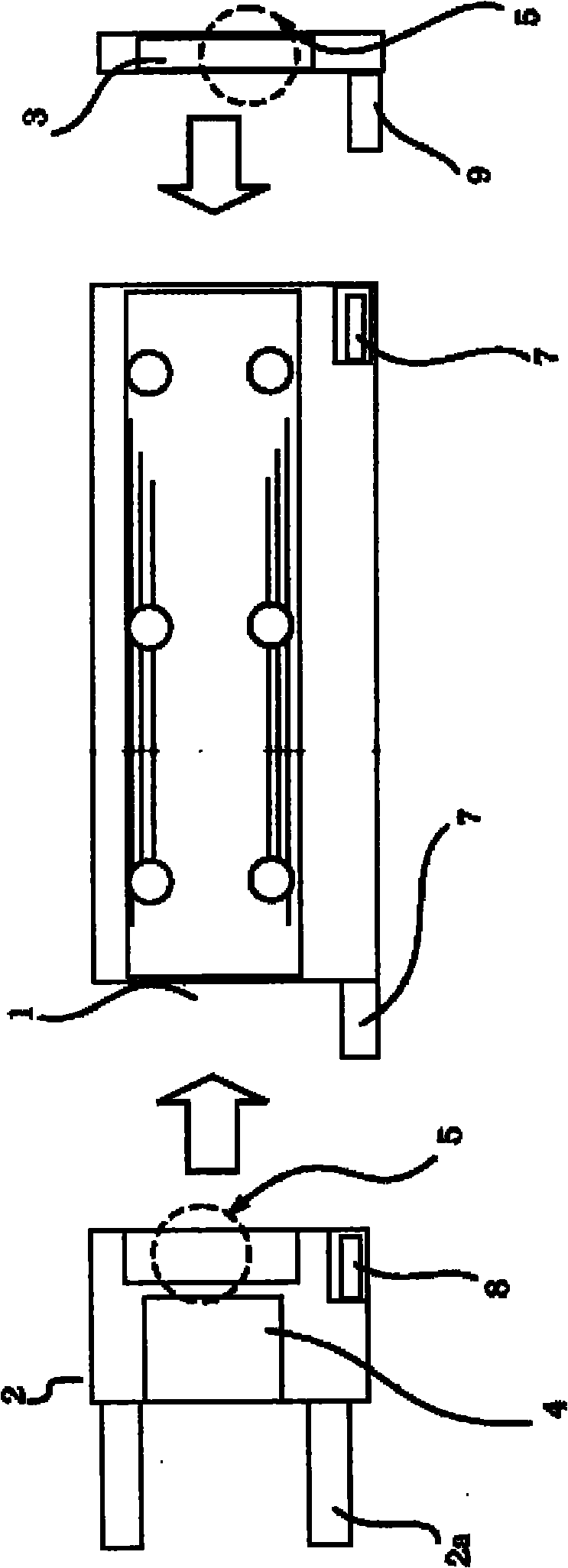

[0049] figure 1 It is a plan view showing the overall structure of the armature of the modular linear motor with iron core according to the first embodiment of the present invention, and is a disassembled view of the modular armature unit, lead wire connection unit, and neutral point unit.

[0050] exist figure 1 Among them, 1 is a modular armature unit, and an m-phase (m is an integer) armature winding (not shown) composed of a plurality of coil groups is installed on an unshown armature core, and the front and rear ends of the unit It is a connector structure that can be used to supply electric power to the armature.

[0051] In addition, 2 is a lead wire connection unit, 3 is a neutral point unit, and 4 is a magnetic pole sensor. 5 is an auxiliary tooth, and the wire part connecting unit 2 and the neutral point unit 3 are the same connector structure as the modular armature 1 .

[0052] The features of the present invention differ from the prior art as follows.

[0053]...

Embodiment 2

[0072] Next, a second embodiment of the present invention will be described.

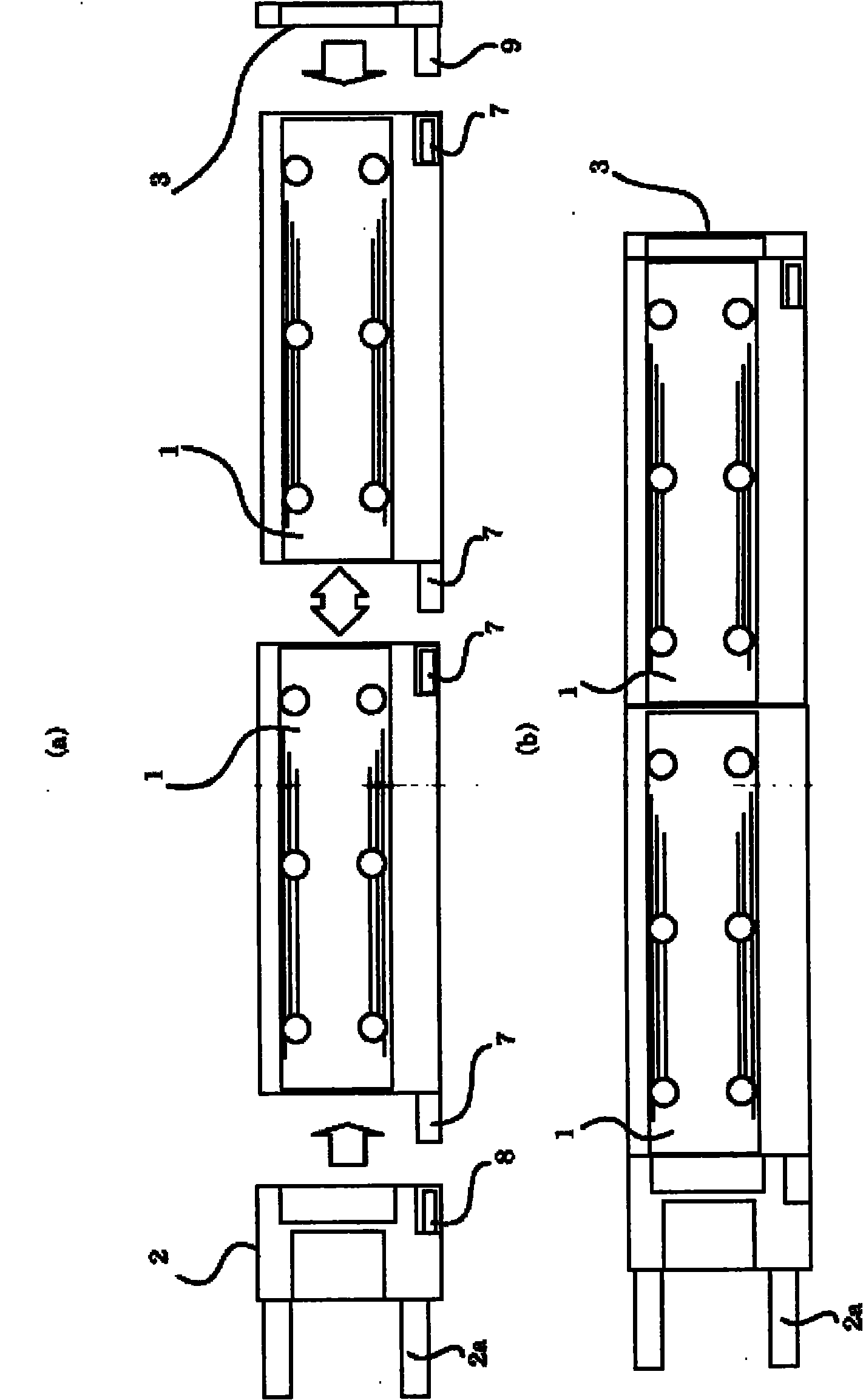

[0073] Figure 4 A plan view showing a parallel-connected lead wire connection unit according to a second embodiment of the present invention, Figure 5 Shows the overall configuration of the armature of a modular linear motor with iron core to which the parallel-connection lead wire connection unit of the second embodiment is applied, (a) is a disassembled plan view of them, and (b) is a combined plan view of them .

[0074] The difference between the second embodiment and the first embodiment is that the armature unit 1, the wire connection unit 2 and the neutral point unit 3 are arranged in n parallel configurations (n=2 in this example), and the wires The part connecting unit 2 is provided with: a distributing circuit not shown, which divides into n the current supplied to the lead part connecting unit 2 from an external power supply not shown; The armature unit 1 supplies current divided by ...

Embodiment 3

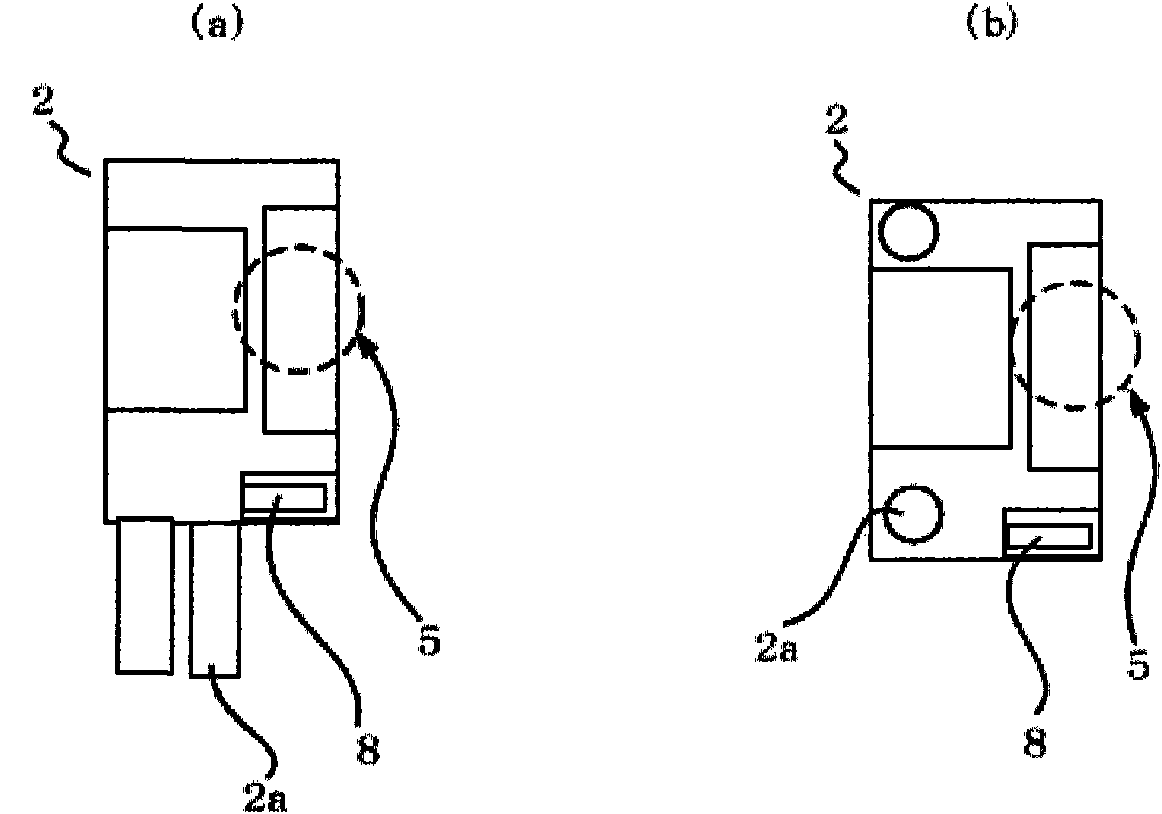

[0083] Figure 6 It is an example of connecting two modular coreless linear motor armatures in series according to the third embodiment of the present invention, (a) is a schematic front view and a side view thereof, and (b) is a side view in which each armature unit is disassembled , (c) is a side view of each armature unit connected.

[0084] exist Figure 6 Among them, 11 is a field magnet, which is composed of magnets 11b installed at equal intervals in the form of opposite poles opposite to each other and polarity alternately changing on the inside of a half-I-shaped field magnet yoke 11a.

[0085] In addition, 12 is an armature unit, and the armature unit 12 is a substrate group 12c made of resin-molded armature windings formed by arranging a plurality of coil groups in the longitudinal direction of the substrate, and fixing the substrate group 12c to the armature base. On the seat 12d, a coreless modular linear motor armature is formed. Furthermore, the front and rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com