Electronic ballast and method for operating at least one first and second discharge lamp

A technology for electronic ballasts, discharge lamps, applied in the field where the rated value of the total current is predetermined to

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

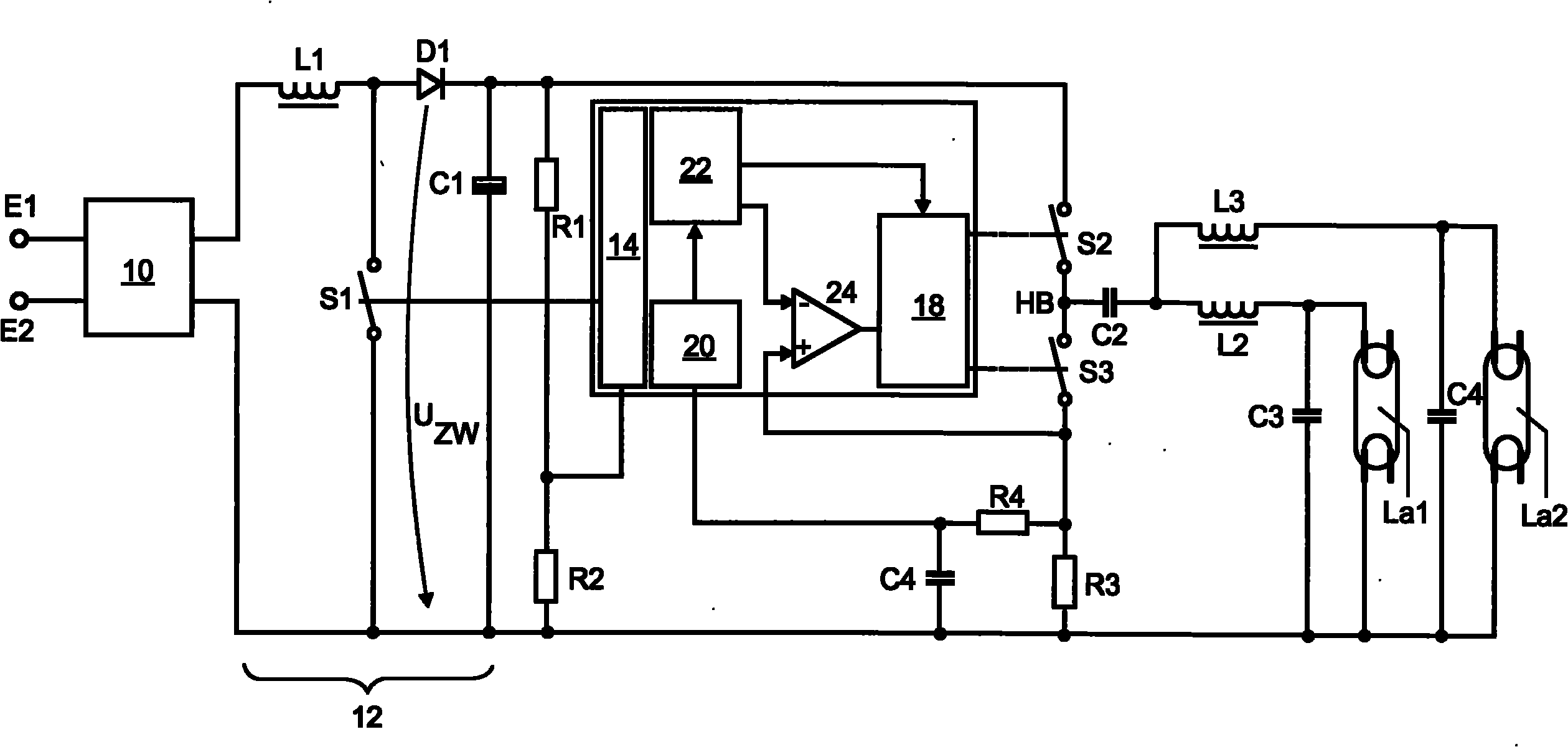

[0017] figure 1 The structure of the electronic ballast for driving the first discharge lamp La1 and the second discharge lamp La2 according to the present invention is schematically shown. On the input side, the ballast comprises a first terminal E1 and a second terminal E2 for connection to the grid voltage U N . This is followed by block 10 which includes the rectifier and components for EMC protection. This is followed by a boost converter 12 comprising an inductor L1, a switch S1, a diode D1 and a capacitor C1. At the output of the boost converter, on the one hand the so-called intermediate circuit voltage U ZW This is supplied to the voltage divider R1 , R2 and on the other hand to the two switches S2 , S3 of the half bridge. The signal tapped off at resistor R2 is fed to unit 14 of microcontroller 16 , unit 14 being used for PFC (power factor correction). For this, in particular switch S1 of boost converter 12 takes into account voltage U sensed by means of resisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com