Bamboo skin scraping, interior wall processing and pressing integrated operation system

A kind of operation system and epidermis technology, which is applied in the direction of mechanical equipment, sugarcane machining, etc., can solve the problems of the overall quality of bamboo that cannot meet the needs of industrial production, and achieve the effect of facilitating industrial production, saving labor and saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0028] The present invention adopts multi-process semi-mechanical or manual processing in order to change the current traditional bamboo processing industry, which has a lot of labor, low output, long time, large floor area, and unstable overall quality of bamboo, which cannot meet the needs of industrial production. Phenomenon.

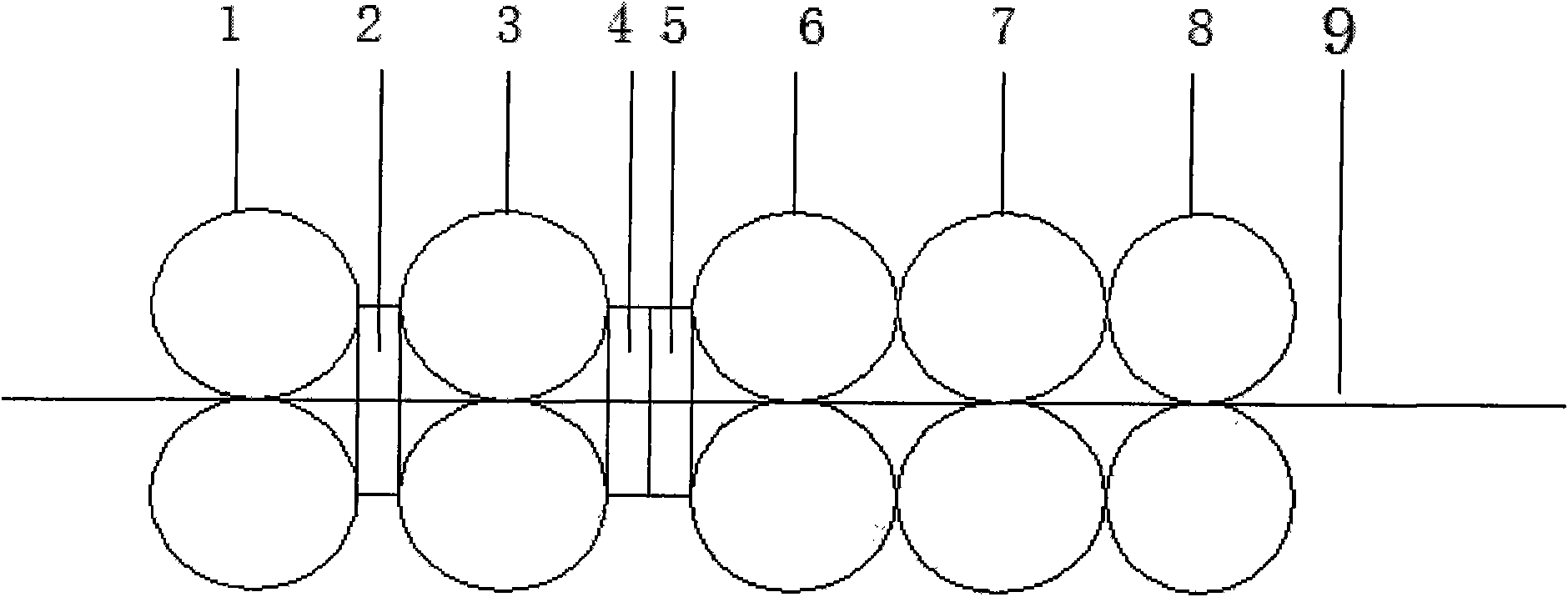

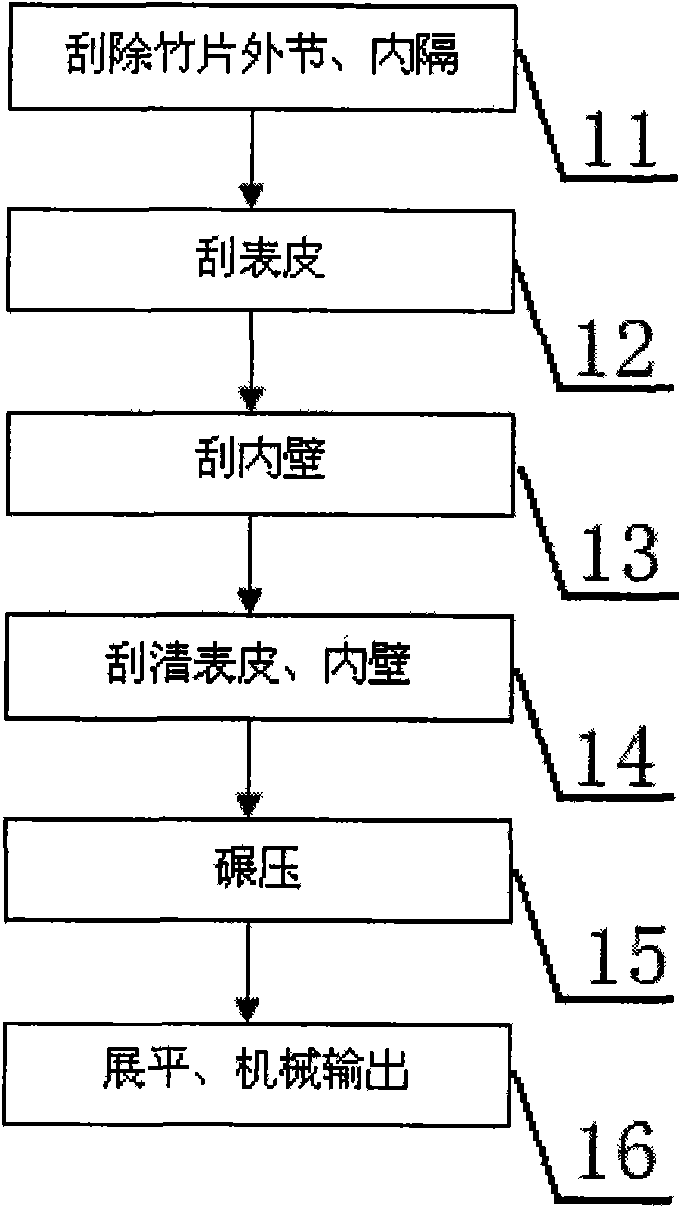

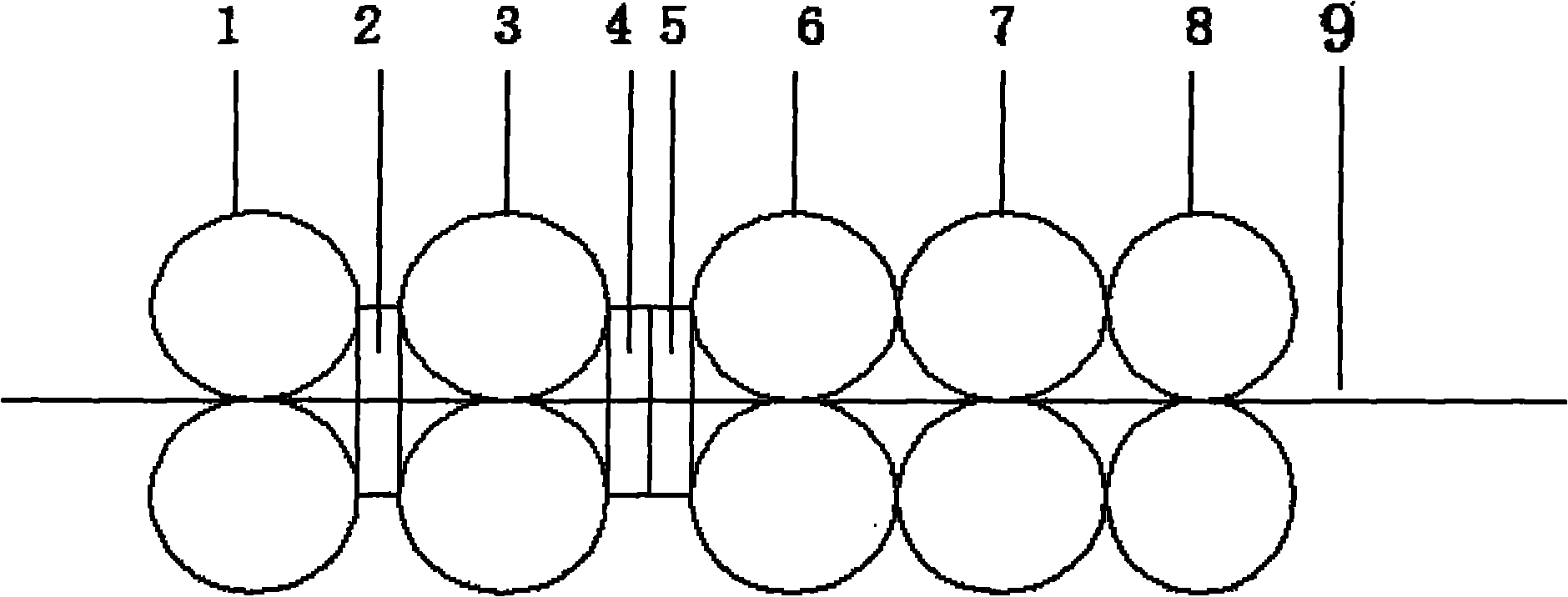

[0029] The technical solution adopted is to provide an integrated operation system for bamboo skin scraping, inner wall treatment and rolling, which includes a first-level flattening device, a first-level scraping device, a second-level flattening device, a comb scraping device, Second-level scraping device, rolling device, and third-level flattening device; the first-level flattening device, first-level scraping devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com