Compact centring device

A centering device and compact technology, which is applied in transportation and packaging, railway car body parts, buffers, etc., can solve the problems of poor automatic recovery performance and excessive volume, and achieve accident prevention, small size, and easy installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

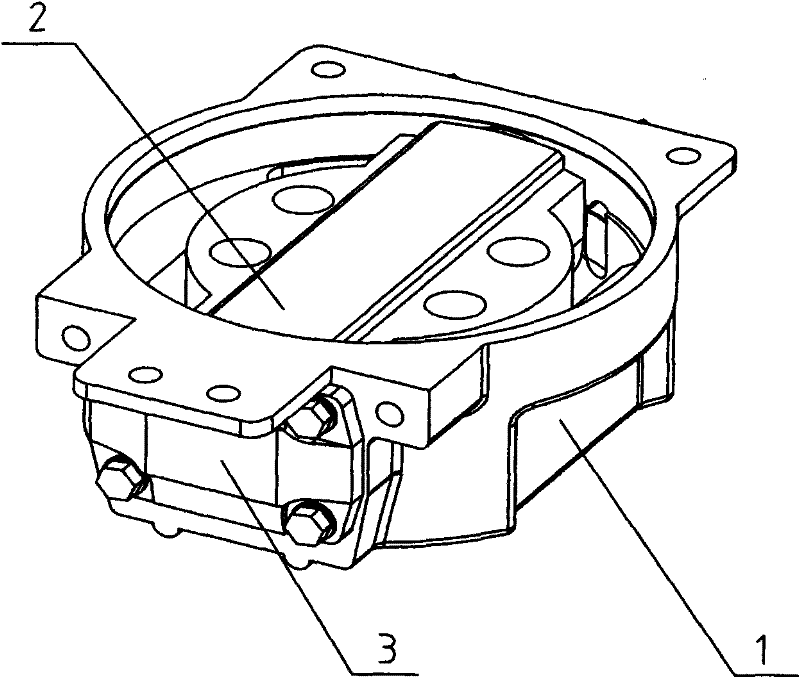

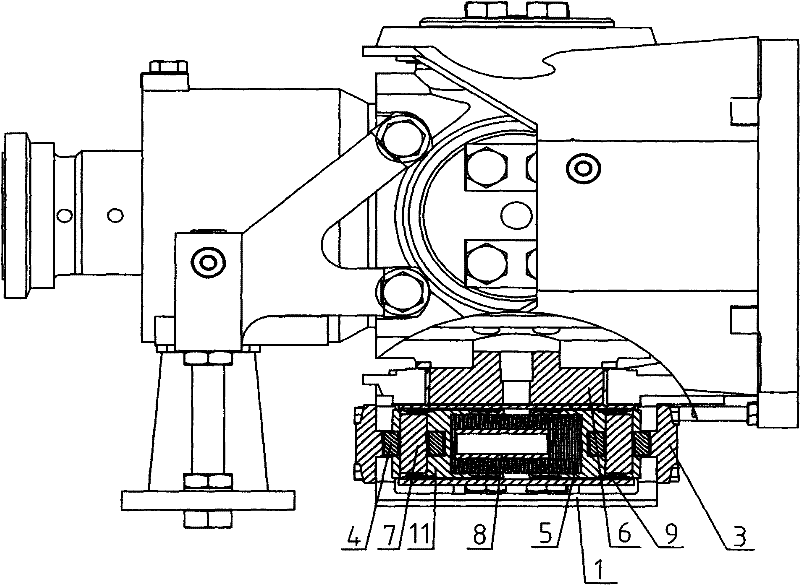

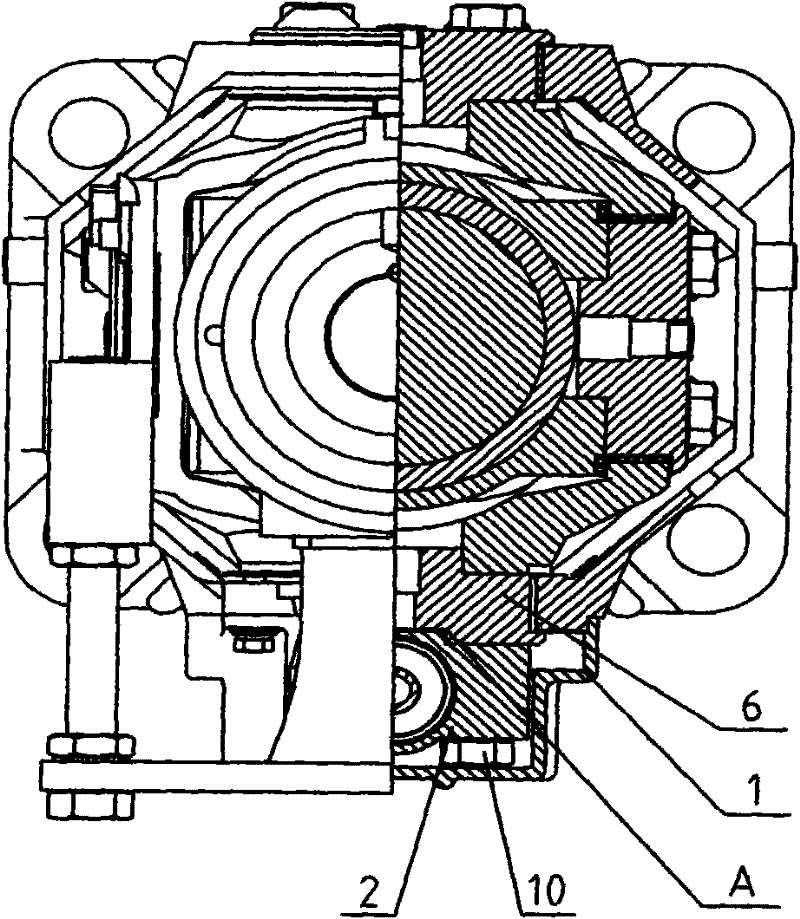

[0014] The specific embodiment of the present invention is as follows: as Figures 1 to 3 As shown, a compact centering device is installed at the bottom of the buffer. The centering device includes a centering sleeve 1, a centering body 2, a roller 4 and a roller plug 3, and a rotating shaft 6. The centering sleeve 1 Installed on the mounting seat of the buffer, and fastened with the roller block 3 by bolts, the mounting seat and the centering sleeve 1 do not rotate when the hook buffer device rotates; the centering body 2 and the rotating shaft 6 are fastened on the buffer by bolts 10 On the buffer system of the device, when the hook buffer device rotates horizontally, the buffer system can drive the rotating shaft 6 and the centering body 2 to rotate together, and transmit the rotational torque through the interference fit surface A; two pistons with pistons are installed in the centering body 2 The piston 11 of the wear sleeve 9 is filled with the disc spring 5, and the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com