Rotational speed control method and device for idle speed of petrol engine and working condition of small accelerator

A gasoline engine, engine speed technology, applied in engine control, machine/engine, electrical control, etc., can solve problems such as cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

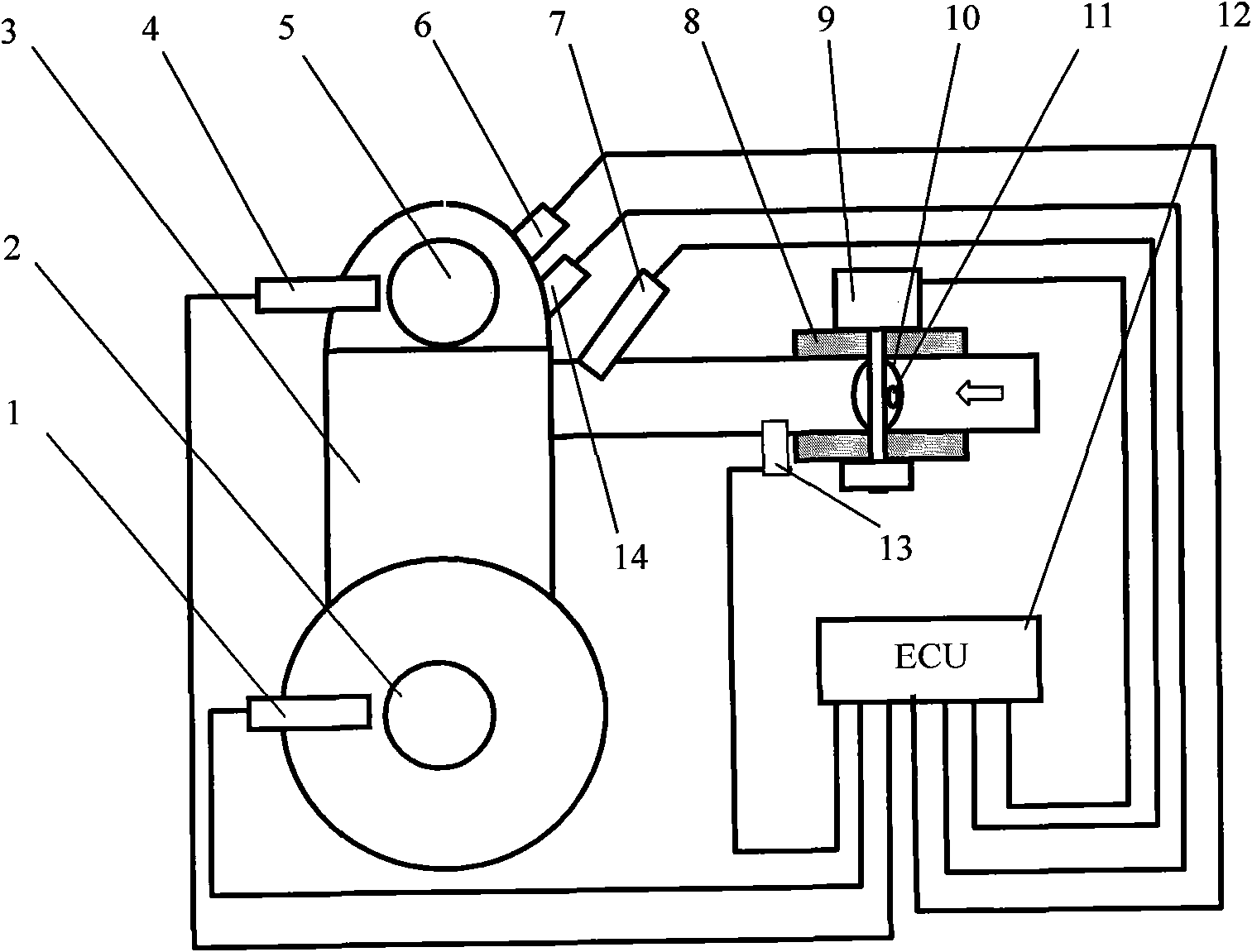

[0049] exist figure 1 In the shown engine system of implementing the present invention, include engine body 3, crankshaft 2, camshaft 5, throttle body 8, electric control unit (ECU) 12, ignition device 14, fuel injection device 7 and various sensors Wait. On the throttle body 8, there is a throttle plate 10 for adjusting the air intake of the engine. On the throttle plate 10, there is a non-adjustable main idle air intake hole 11, the size of which is determined according to the minimum air intake required for the stable idle speed of the engine. For example, for the motorcycle engine of 125-150cc displacement, the main idle air intake hole 11 can be designed as a circular hole of diameter 2-2.5mm; for the motorcycle engine of 50-110cc displacement, the main idle air intake hole 11 can be designed as A round hole with a diameter of 1.2-2.2mm. Of course, besides the idle air flow flowing in through the main idle air intake hole 11, a certain amount of idle air also flows thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com