Tube-in-tube illuminating lamp adopting cold cathode lamp tube

A cold cathode and tube-in-tube technology, which is applied to lighting devices, lighting and heating equipment, and parts of lighting devices. No problem, achieve the effect of no damage, automatic optimization of lamp parameters, and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

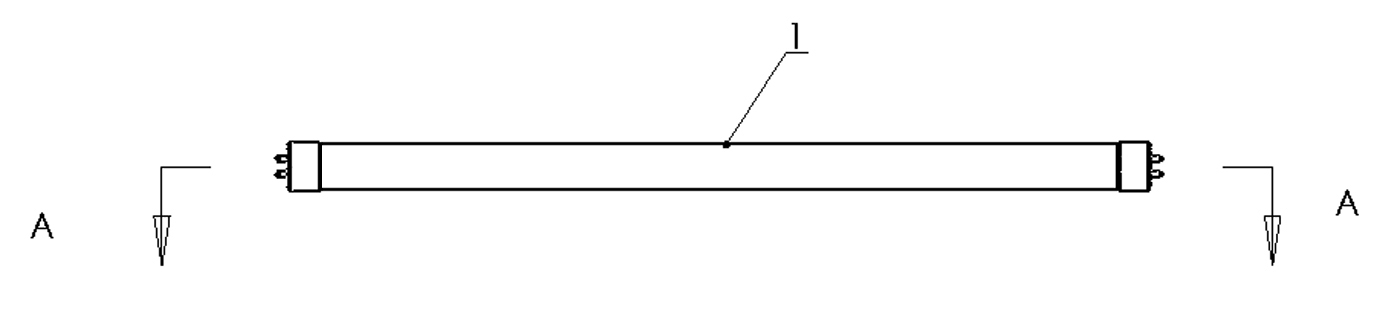

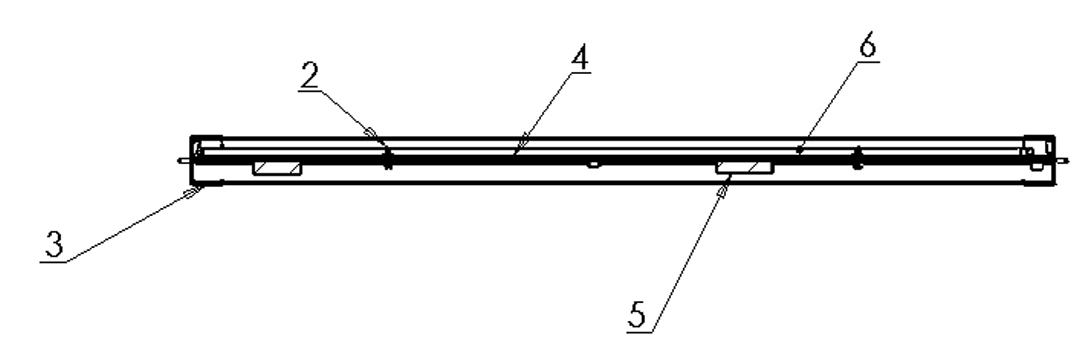

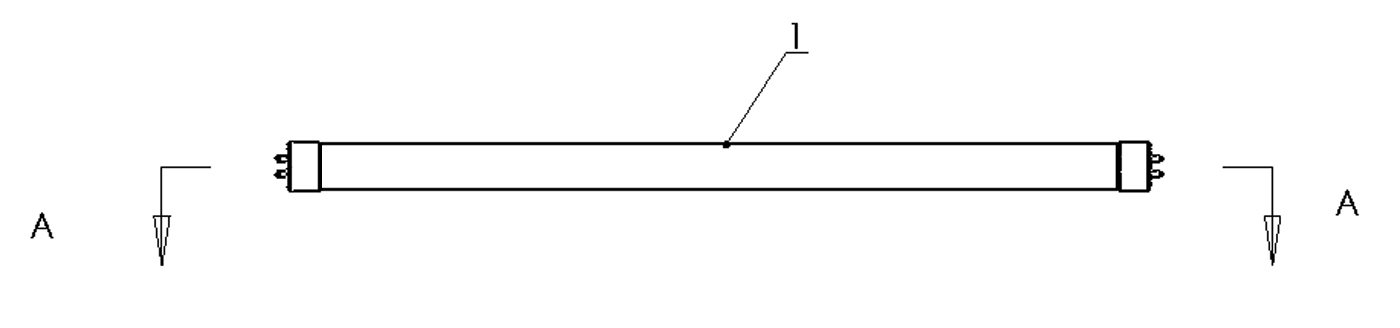

[0014] A tube-in-tube lighting lamp using a cold-cathode fluorescent tube. The outer tube 1 is provided with a reflective sheet 4. The cold-cathode fluorescent tube 6 is installed on the working side of the reflective sheet 4 through the tube clamp 2, and the other side of the reflective sheet 4 is installed There is an inverter 5, and the inverter 5 is electrically connected to the output end of the cold cathode lamp tube 6, and the electrodes of the input end of the inverter 5 are led out to both ends of the outer tube 1 through the lamp cap 3. The outer tube adopts T5 / T8 specification. In this way, the existing T5 / T8 specification lamp holders can be used and directly clamped on the existing lamp holders, thereby saving costs. The working side of the reflective sheet 4 referred to here is exactly the reflective side of the reflective sheet.

[0015] The cold cathode lamp tube 6 is U-shaped or straight tube-shaped, with a length of 500-1200mm.

[0016] The diameter of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com