Jet flow type smoke exhaust ventilator and fluidic generator thereof

A technology of jet flow generator and range hood, which is applied in the direction of oil fume removal, heating method, household heating, etc., to achieve the effect of solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

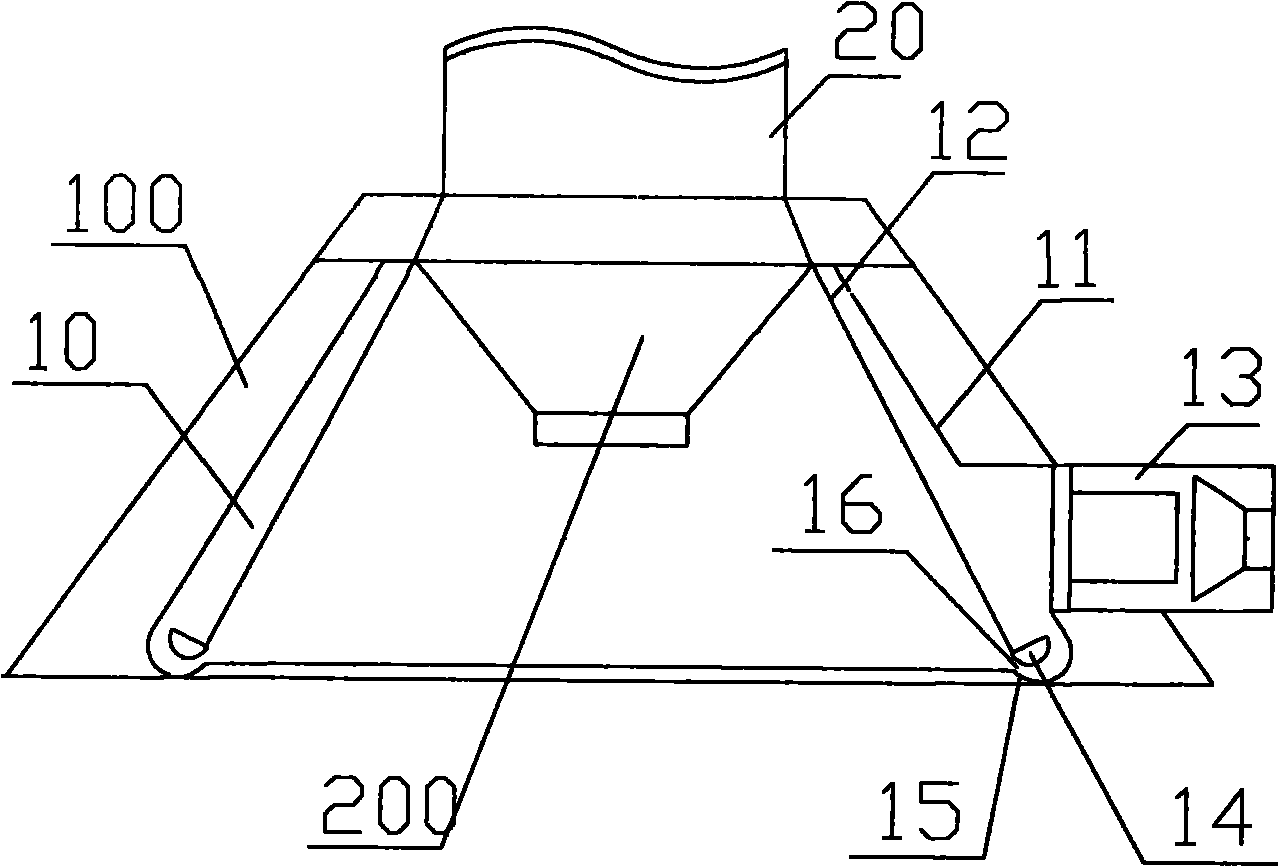

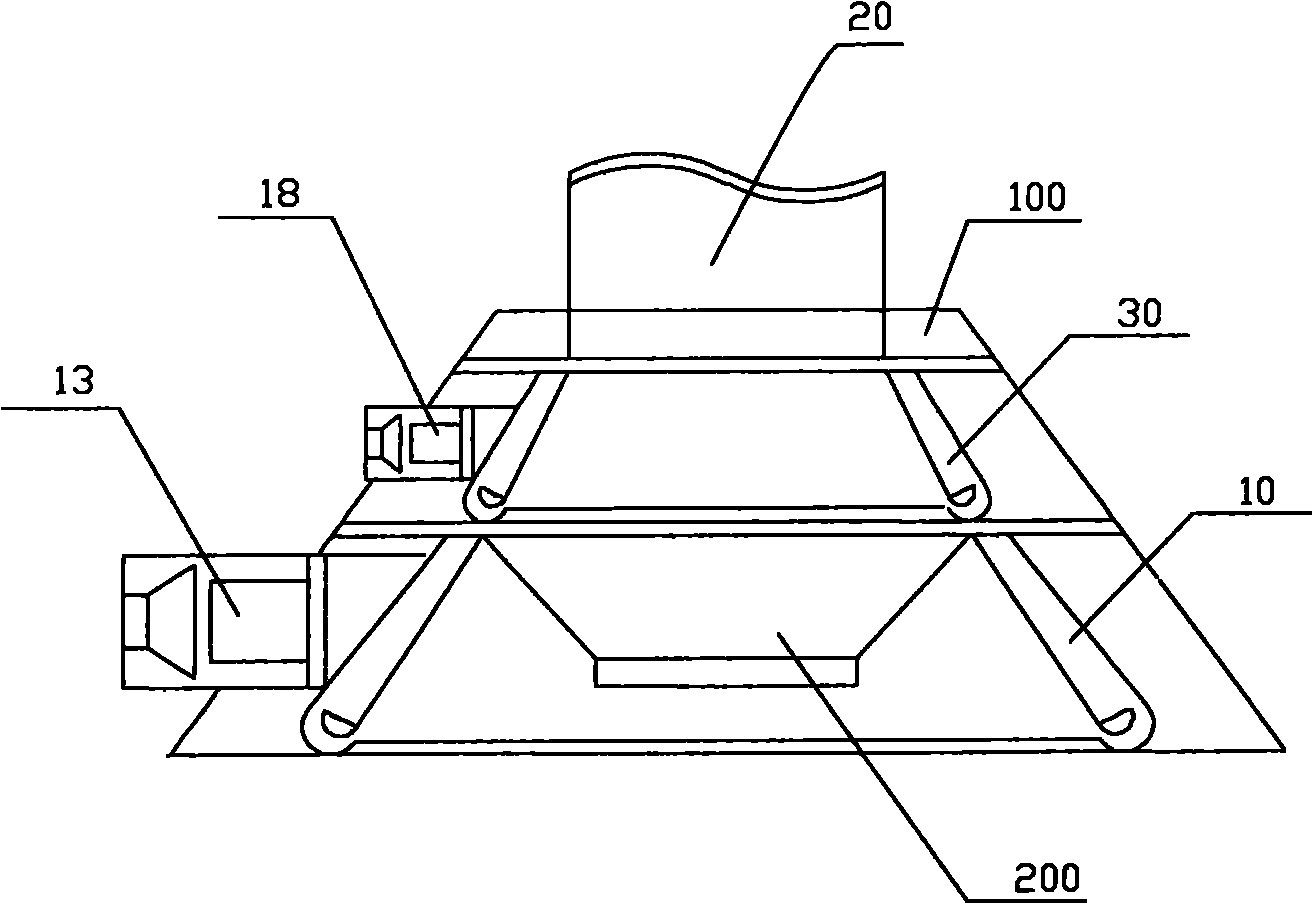

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

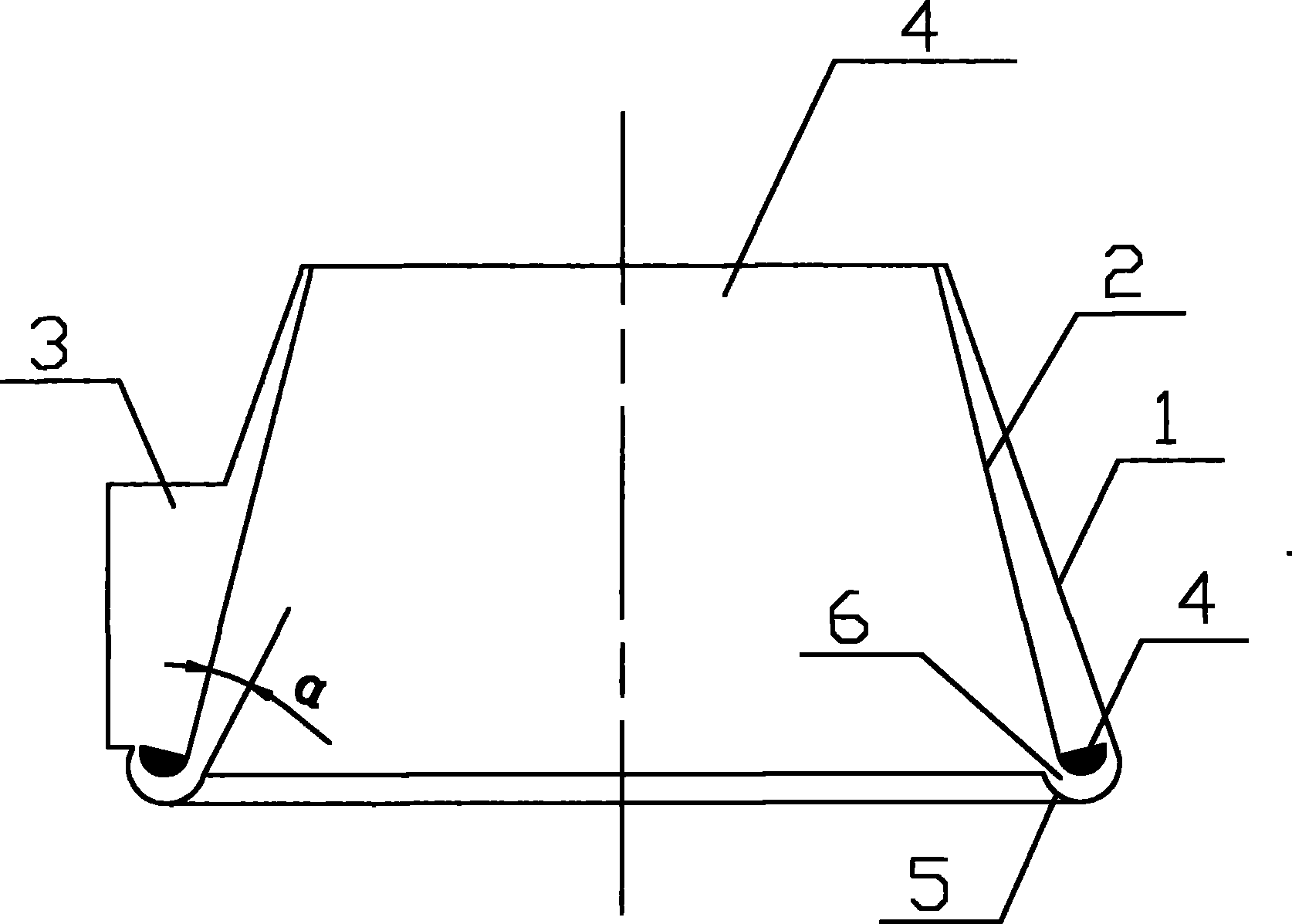

[0023] Such as figure 1 As shown, the jet generator for range hood provided by the present invention includes an outer casing 1 and an inner casing 2 arranged inside the outer casing 1, and the materials of the inner and outer casings can be made of plastics, iron sheets and other materials.

[0024] Both the outer shell 1 and the inner shell 2 are trumpet-shaped and the outer shell 1 is provided with an air inlet 3, the top edges of the inner and outer shells 1, 2 are connected to each other as one, and the bottom edge of the inner shell 2 is provided with an air inlet facing the outer shell. 1, the lower edge of the outer casing 1 is provided with a second hemming portion 5 facing the inner casing 2, and the gap between the second hemming portion 5 and the first hemming portion 4 forms a jet channel 6 . The angle α between the tangent direction at the opening of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com