Compressor bin structure of refrigerator

A technology for compressor compartments and refrigerators, applied in lighting and heating equipment, household appliances, household refrigeration devices, etc., which can solve the problems of difficult shape fixation, high material cost, high mold cost, etc., so as to prevent bubble leakage and reduce production cost , the effect of good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

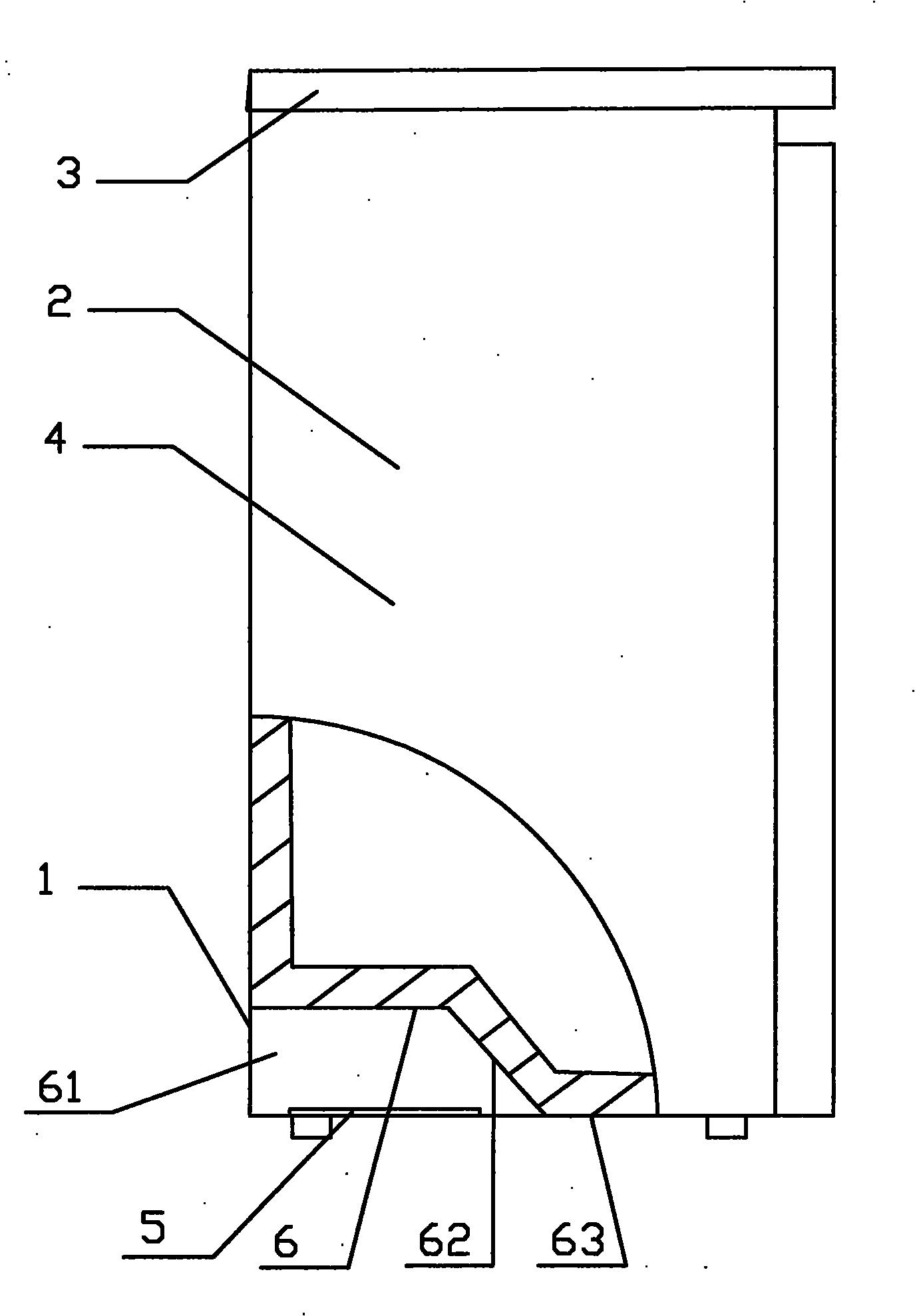

[0016] figure 1 Shows the structure of the refrigerator compressor compartment at present, see figure 1 , the box of the refrigerator is composed of a top cover 3, left and right side panels 2, and a rear panel 4, and a compressor compartment 1 is arranged at the bottom of the back of the cabinet, and the compressor compartment 1 is composed of left and right side panels 2, a compressor supporting plate 5, Back floor assembly 6 surrounds, and at present, back floor assembly is made up of left and right reinforcing plates 61, base plate 63 and bent plate 62 assembly, and wherein left and right reinforcing plates 61, base plate 63 are sheet metal parts, and bent plate 62 is calcium plastic cardboard.

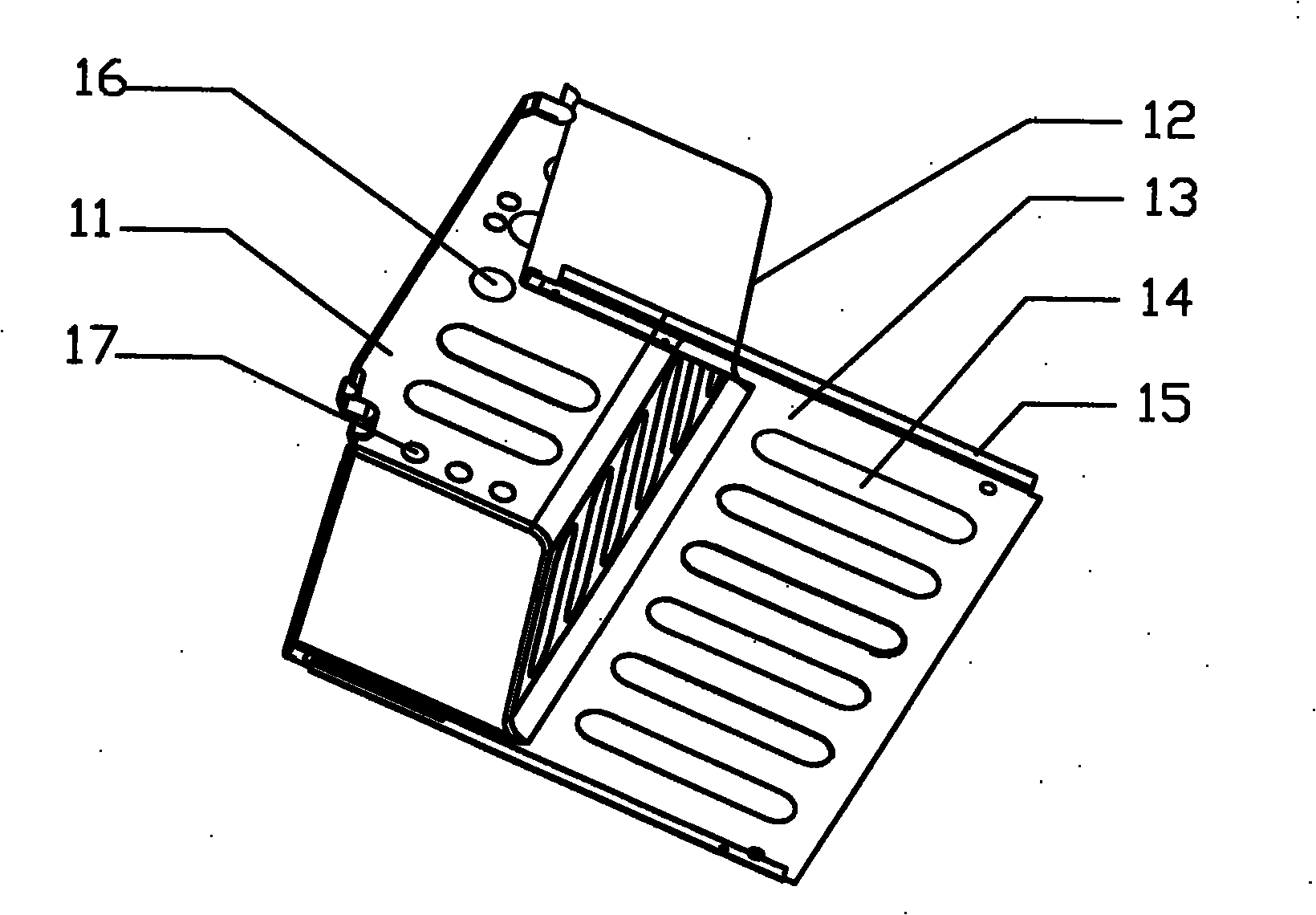

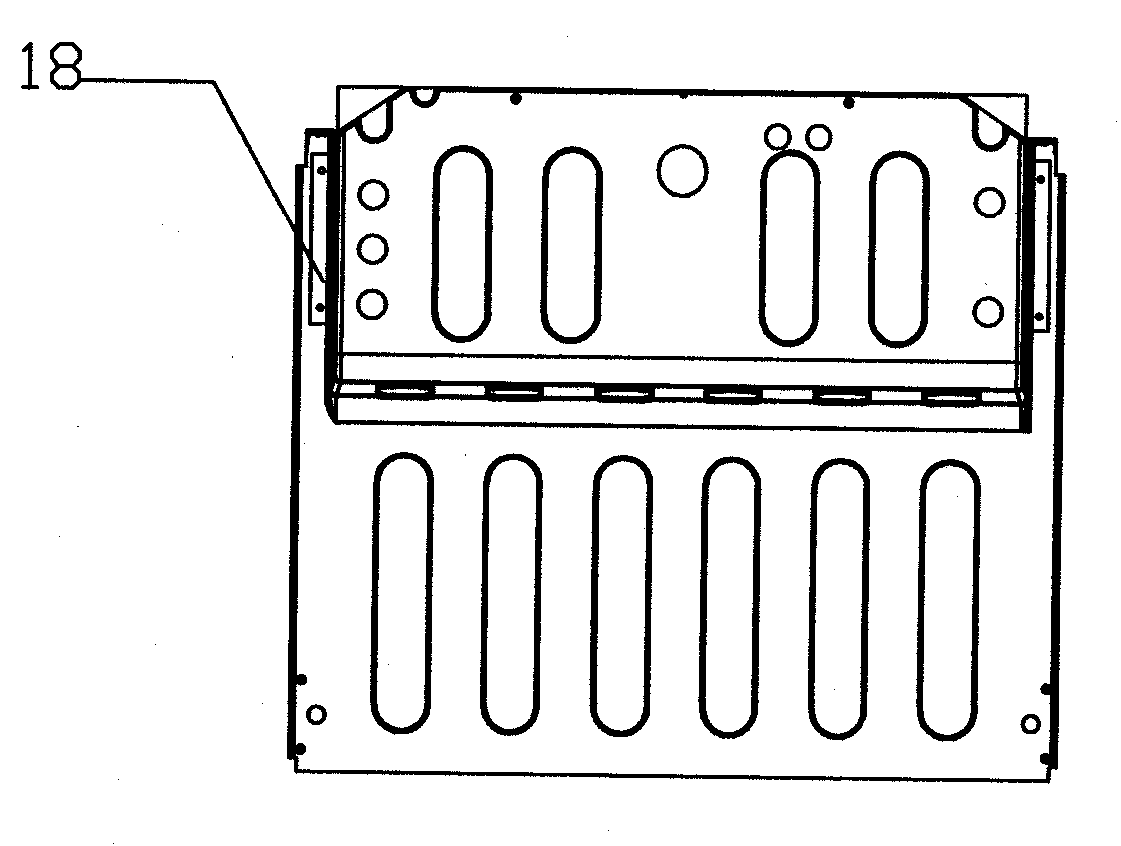

[0017] see figure 2 --3. The structure of the refrigerator compressor chamber 1 of the present invention is composed of the left and right side panels 2 of the refrigerator, the compressor support plate 5 and the rear floor part. 13 and the side part 12, wherein the side part 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com