Control method of equipment containing pressure sensor

A pressure sensor and control method technology, applied in mechanical pressure/force control, electrical program control, non-electric variable control, etc., can solve problems such as unfavorable pressure sensor application, cumbersome, complex and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

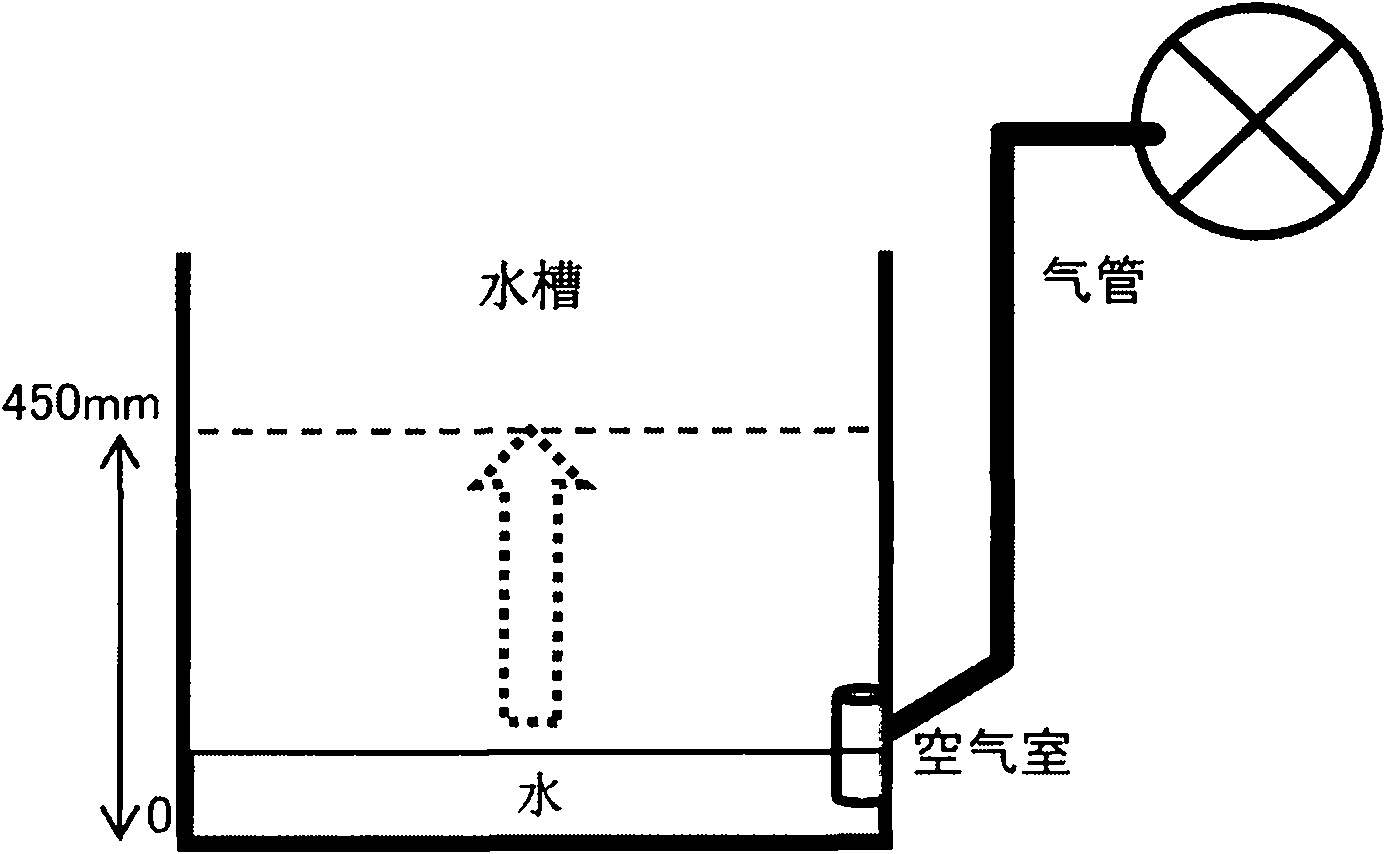

[0046] Let’s take the washing machine as an example, such as figure 2 As shown, the water tank inside the washing machine is provided with an air chamber communicating with the inside of the water tank. The air chamber is set at the bottom of the water tank. As the water level in the water tank rises, the water in the water tank will gradually enter and flood the air chamber. The chamber is connected to the pressure sensor through the air pipe, so as to detect the air pressure in the air chamber and obtain the information of the water level in the sink; in this embodiment, the initial position of the frequency signal curve of the pressure sensor is the zero of the water level in the sink Water level position, at this time the water in the sink does not enter the air chamber.

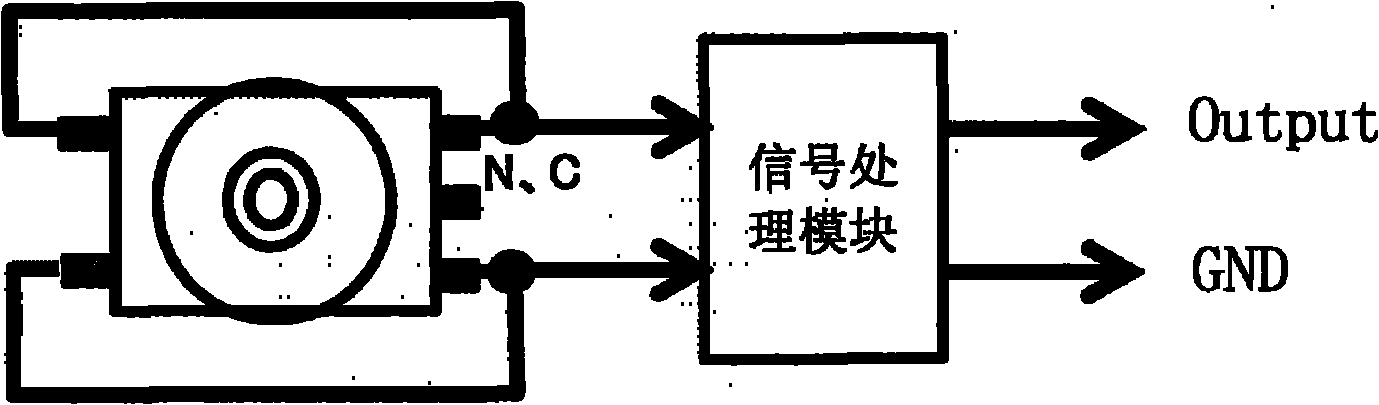

[0047] Such as image 3 As shown, the signal output terminal of the pressure sensor processes the frequency signal detected by the pressure sensor through the signal processing module, and transmits it to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com