Semi-finished complete denture and production method

A technology of complete dentures and semi-finished products, applied in the field of dentures, can solve problems such as vertical distance changes, long cycle times, and difficult to guarantee the quality of dentures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

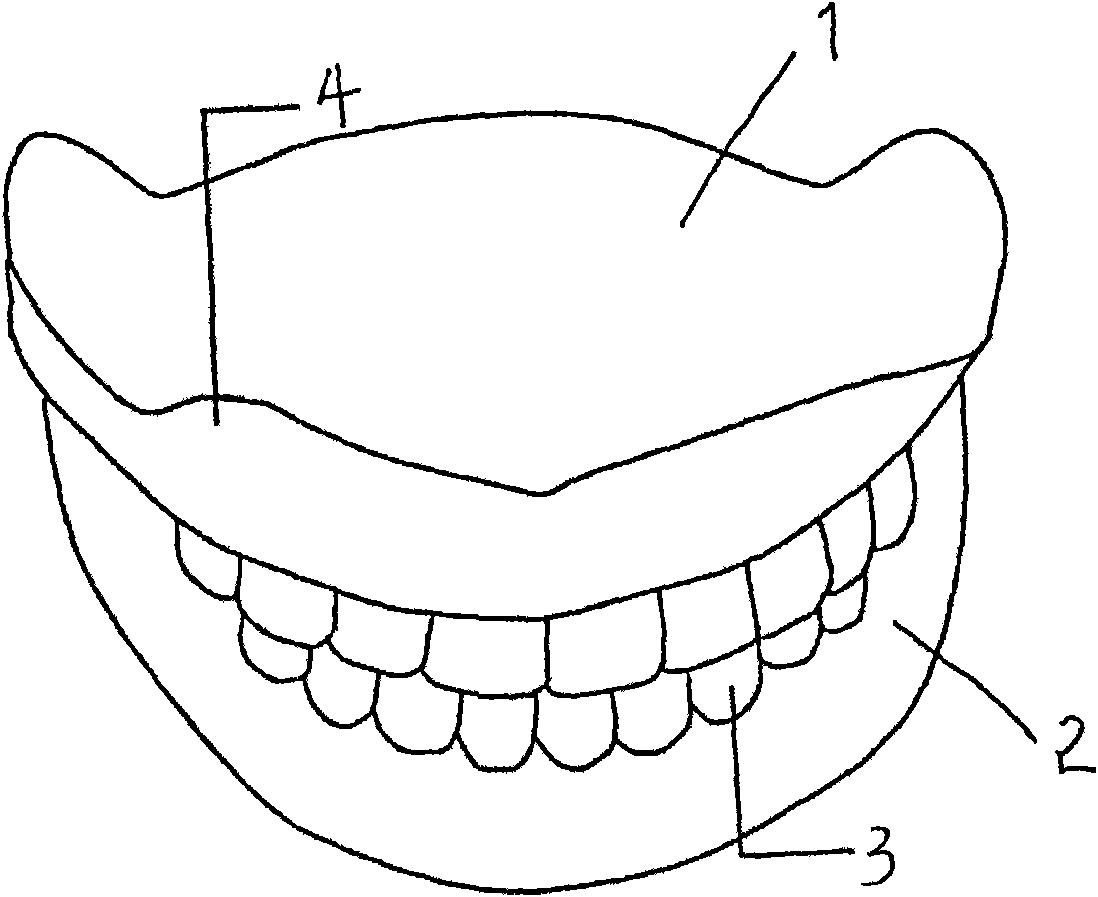

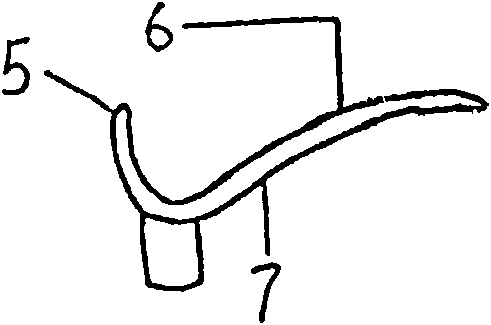

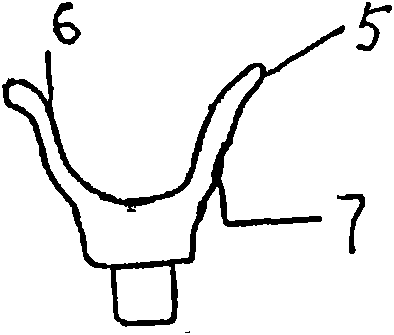

[0013] People's face shapes can be basically divided into five types, round, oval, pointed, square, small up and big down. The semi-finished complete denture of the present invention is correspondingly divided into five styles, each style semi-finished full mouth The denture is composed of the upper jaw 1 and the lower jaw 2. The upper and lower jaws both include the denture 3 and the base 4. The thickness between the base mucosa tissue surface 6 and the base mucosa smooth surface 7 of the base 4 is 0.5mm-0.8mm. The edge 5 of each part of the support has a processing allowance of about 2mm along its extension direction, that is, the edge of the base at the turning point of the vestibular groove at the front of the maxilla extends upwards by 2mm. The turning point of the lateral vestibular groove at the anterior part of the mandible extends downward for 2 mm, the junction of the medial mouth floor mucosa and the alveolar ridge mucosa extends downward for 2 mm, and the posterior ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap