Low-section water tank for integrated carrying-type railway vehicle

An integral bearing, railway vehicle technology, applied in locomotives and other directions, can solve the problems of reducing effective volume, limited water tank space, and low vertical height, and achieve the effect of improving bearing capacity and strength, simple installation structure, and reducing section height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

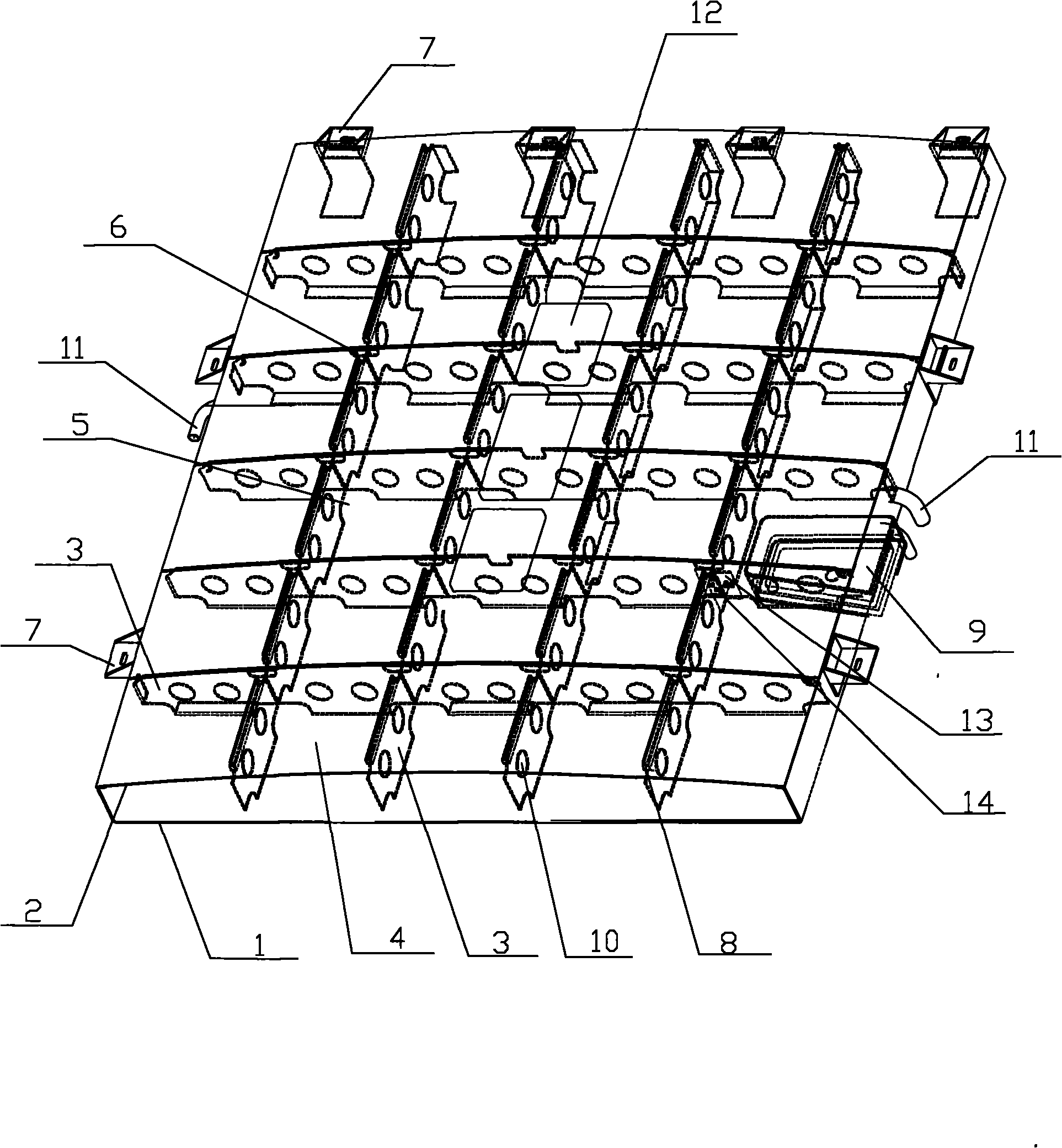

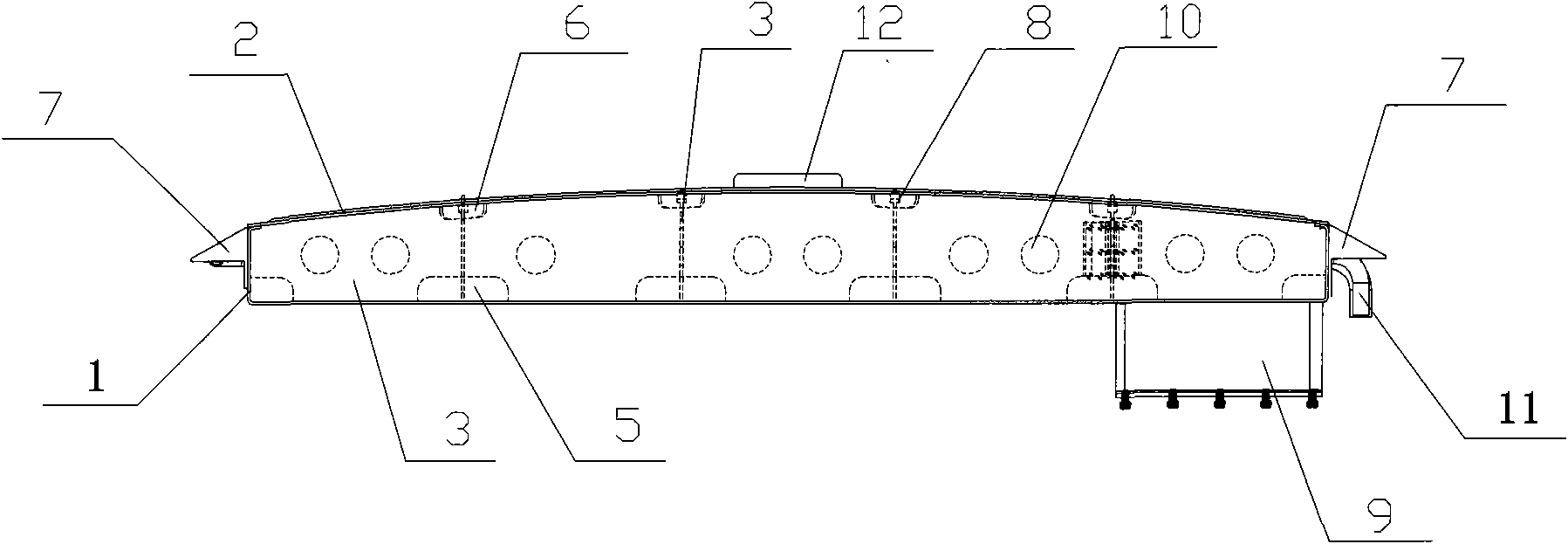

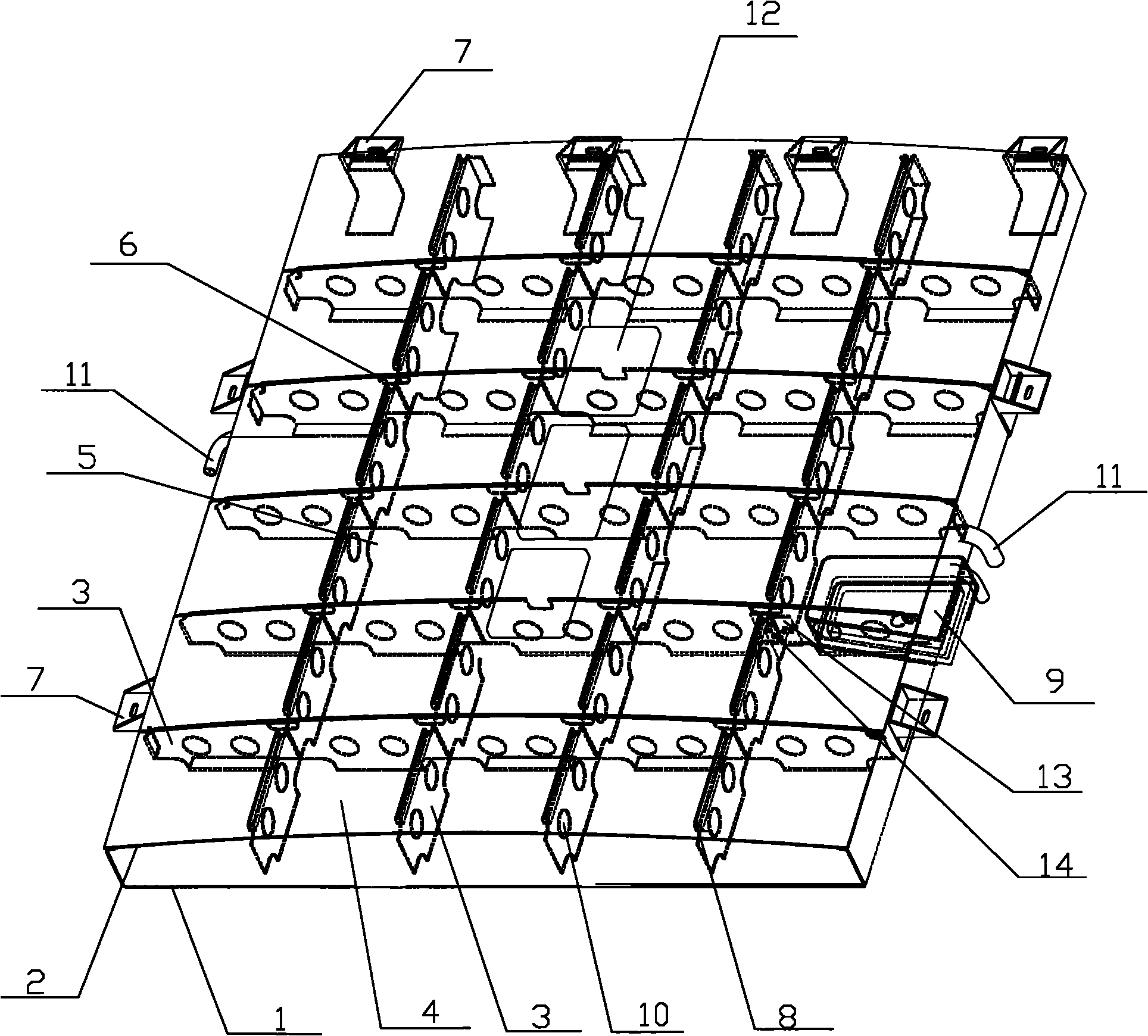

[0017] like figure 1 and figure 2 As shown, a low-section integrated load-bearing railway vehicle water tank includes a tank body 1, a top cover 2 and a wave-proof plate 3 installed in the tank body 1, and the tank body 1 is provided with a water inlet, a water outlet and an overflow port. , and the overflow pipe 11 and the overflow device 12 are provided accordingly.

[0018] Usually, the main body of the wave-proof plate 3 is a plane metal plate with at least a plurality of through holes 10 on it. The impact force of the water flow is reduced. Generally, multiple anti-wave plates 3 are installed in the water tank. Due to the design of the multiple anti-wave plates 3, the high-speed impact of the water in the water tank on the water tank wall is effectively reduced when the train is running, and the deformation of the water tank wall is avoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com