Method and device for treating polymer-containing sewage by using high-gradient agglomerated air floatation

A sewage treatment method and coalescing air flotation technology, which is applied in the direction of flotation water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of easy increase of equipment corrosion and aging oil , Dealing with increased difficulty and other issues, to achieve the effect of saving one-time investment, recovering crude oil with high quality and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

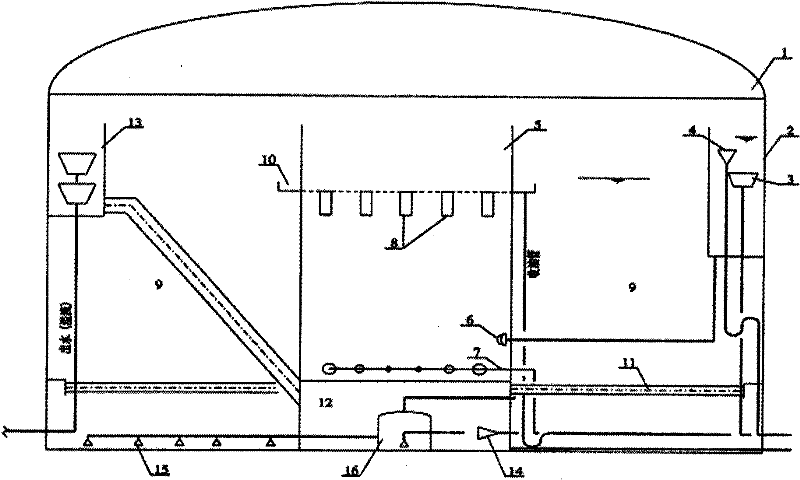

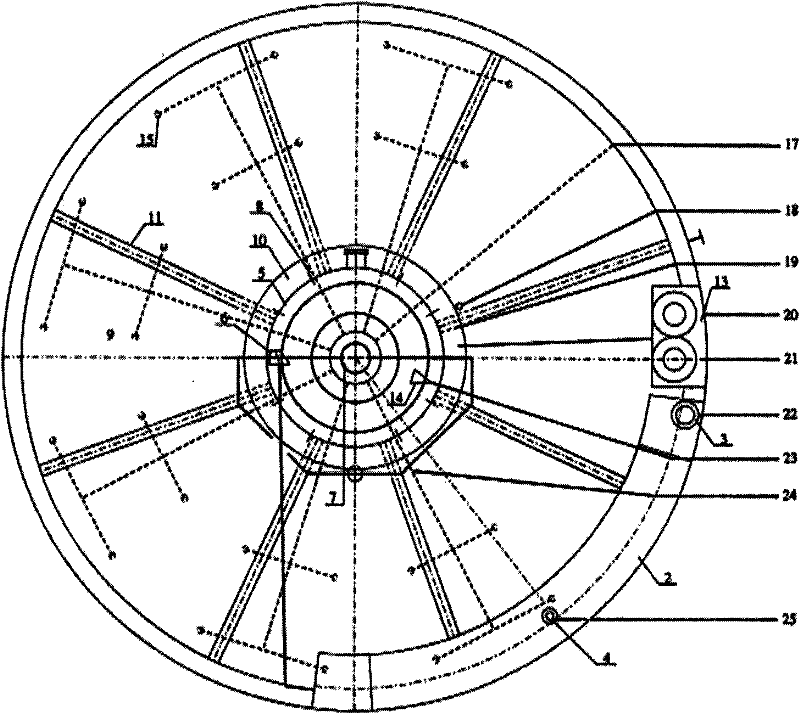

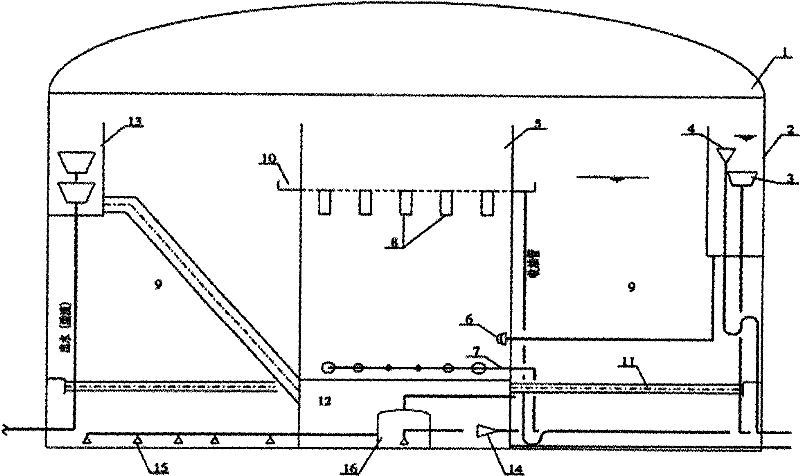

[0033] The oily sewage first enters the coalescing chamber 2, and after the water is distributed by the water distribution port 3, it is coalesced by horizontal and lateral baffles, and the dispersed oil and emulsified oil in the water are coalesced to form large oil droplets, which float together with the slick oil. The oil receiving bell mouth 4 is discharged. At the same time, part of the suspended matter settles here and is discharged through the bottom drain hole.

[0034] The treated water enters the coalescing air flotation chamber 5 through the water inlet nozzle 6, where the sewage forms a high-gradient flow field through high-speed jetting, causing small oil droplets to collide and coalesce again to form large oil droplets. At the same time, the pressure dissolved air water flows out through the bottom dissolved air water distribution pipe 7, where the pressure of the dissolved air water is instantly reduced, so that the gas in the water is released quickly, forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com