Hard alloy blade for improving cutting edge structure

A cemented carbide insert and cutting edge technology, which is applied to tools for lathes, accessories of toolholders, metal processing equipment, etc. To avoid problems such as poor wear resistance of the surface, it can achieve the effect of avoiding knife burning, improving edge strength and avoiding wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

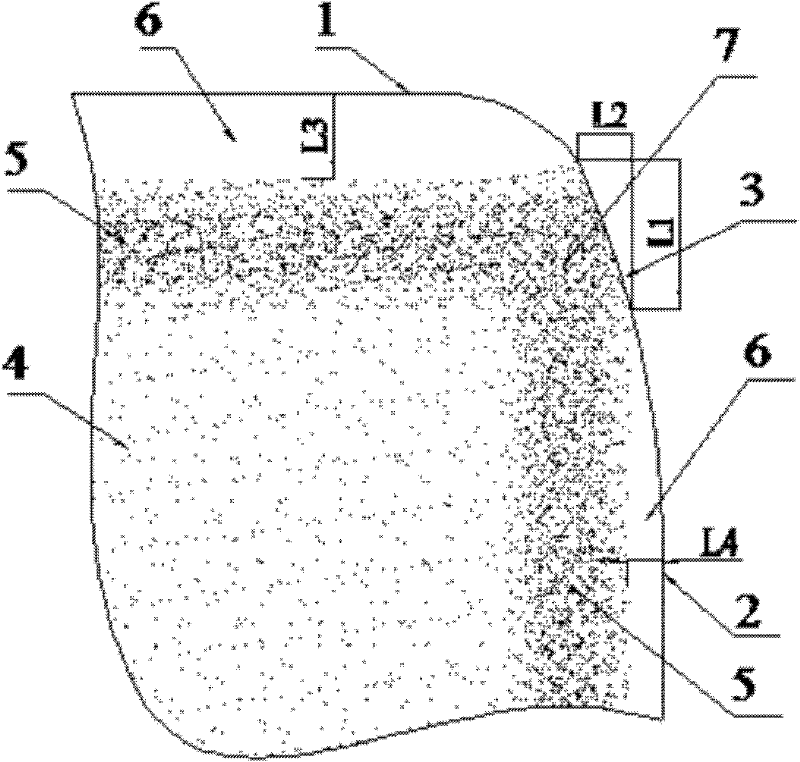

[0019] a kind of like figure 1 The cemented carbide insert with improved cutting edge structure shown includes a cutting edge 3 formed by the intersection of the rake face 1 and the flank face 2. All alloys present a gradient change structure, the gradient change structure refers to the transition from the homogeneous alloy zone 4 of the inner layer to the cubic carbonitride enriched zone 5, and then to the binder phase enriched surface zone 6, the cutting edge The intersection region 7 of the gradient structure on both sides of 3 at the cutting edge 3 is a cubic carbonitride enriched region 5, and the junction region 7 basically does not contain the binder phase enriched surface region 6, which is exposed on the surface of the cutting edge 3 The length L1 of the cubic carbonitride-rich surface region in the direction perpendicular to the rake face 1 is about 40 μm, and the cubic carbonitride-rich surface region exposed on the surface of the cutting edge 3 is in the direction ...

Embodiment 2

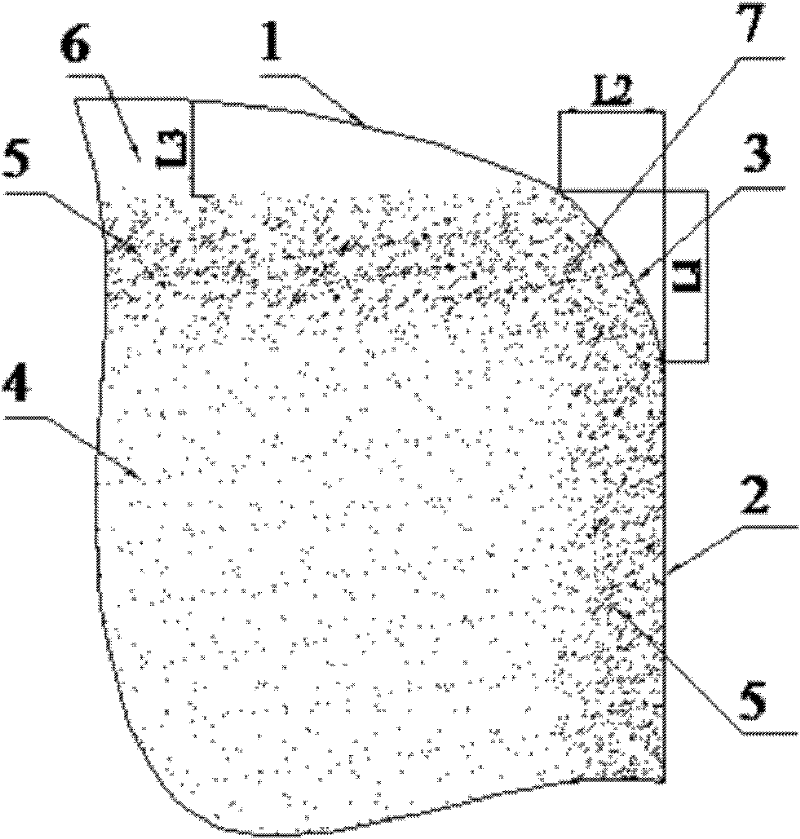

[0028] a kind of like figure 2 The cemented carbide insert with improved cutting edge structure shown includes a cutting edge 3 formed by the intersection of the rake face 1 and the flank face 2. All alloys present a gradient change structure, the gradient change structure refers to the transition from the homogeneous alloy zone 4 of the inner layer to the cubic carbonitride enriched zone 5, and then to the binder phase enriched surface zone 6, the cutting edge The intersection region 7 of the gradient structure on both sides of 3 at the cutting edge 3 is a cubic carbonitride enriched region 5, and the junction region 7 basically does not contain the binder phase enriched surface region 6, which is exposed on the surface of the cutting edge 3 The length L1 of the cubic carbonitride-rich surface region in the direction perpendicular to the rake face 1 is about 40 μm, and the cubic carbonitride-rich surface region exposed on the surface of the cutting edge 3 is in the direction...

Embodiment 3

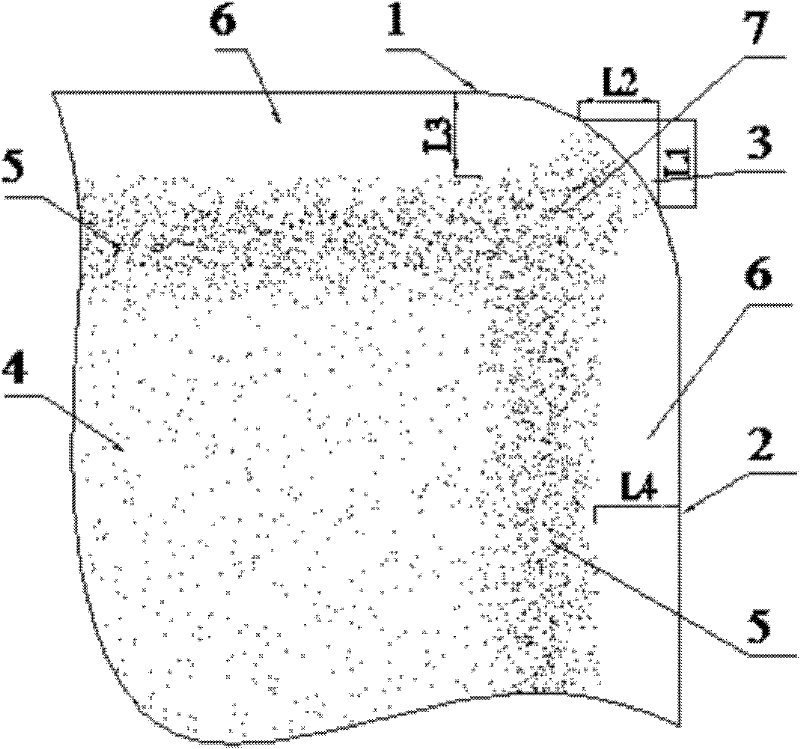

[0031] On the basis of the cemented carbide insert with improved cutting edge structure obtained in the above-mentioned embodiment 2, the coating method is carried out according to the coating method described in embodiment 1, and the cemented carbide coating with improved cutting edge structure of the present embodiment is obtained. Layer blades.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com