Energy-saving aluminum-plastic sliding window

A sliding window, energy-saving technology, applied in the installation of window glass, wing sash frame, sealing device, etc., can solve the problems of poor sealing performance, reduced sealing and thermal insulation performance, and more materials, so as to strengthen the sealing and thermal insulation effect, improve the Insulation performance, the effect of reducing the use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

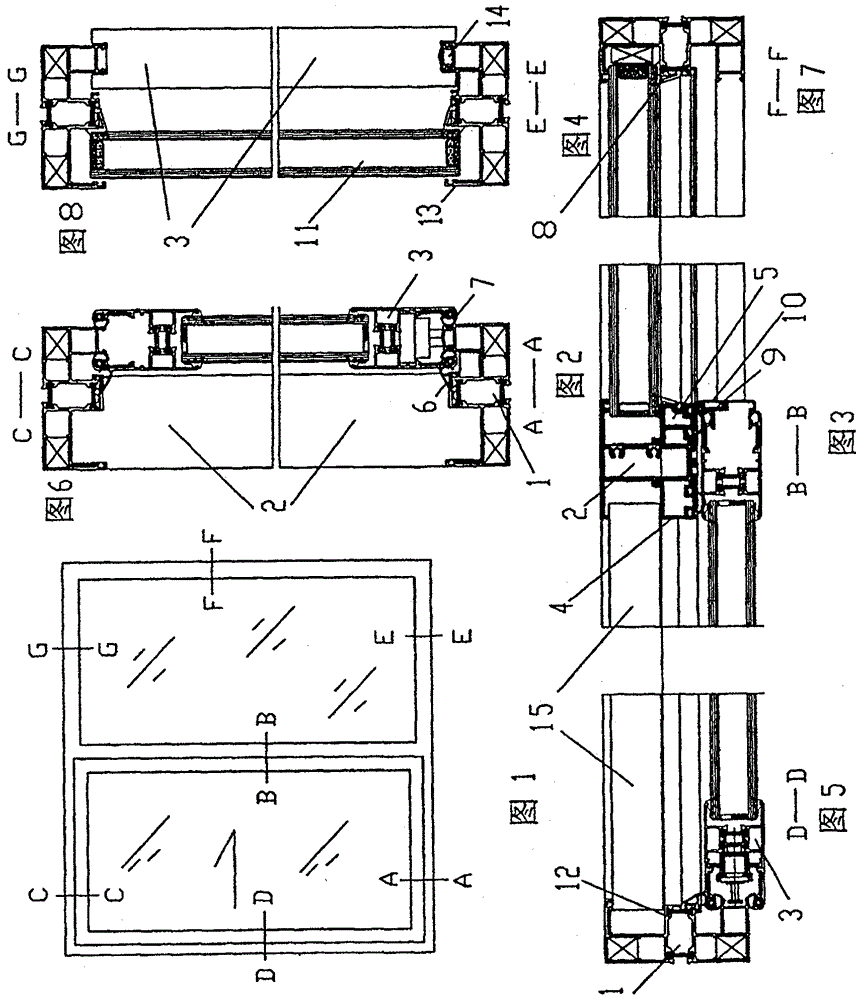

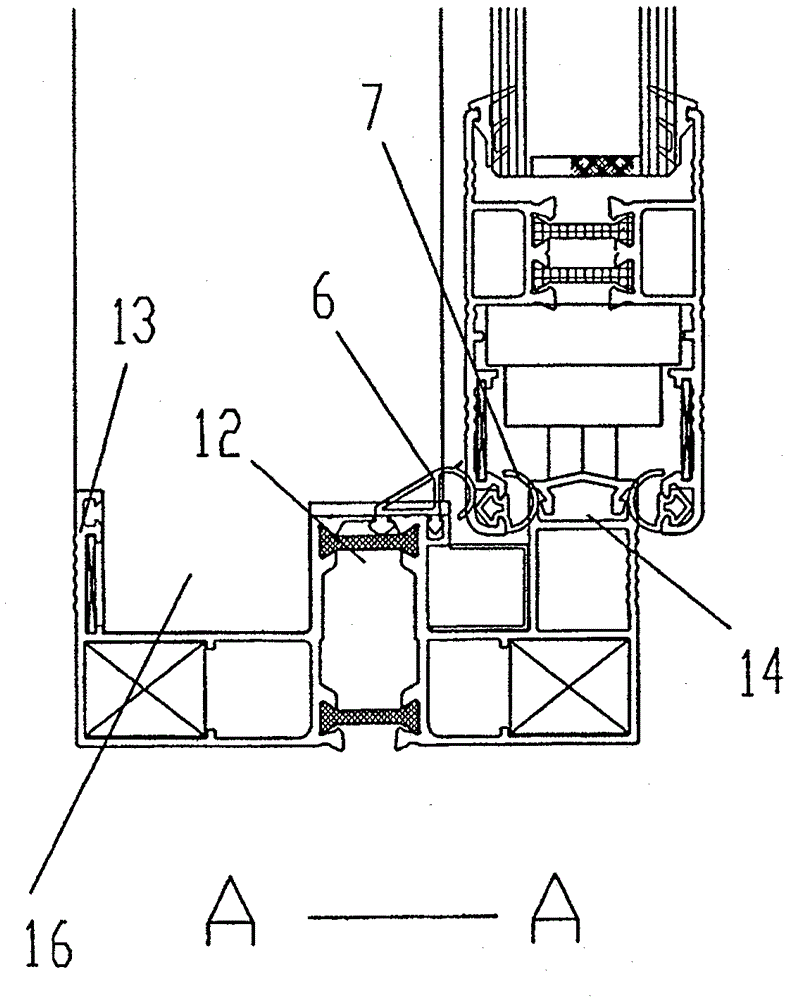

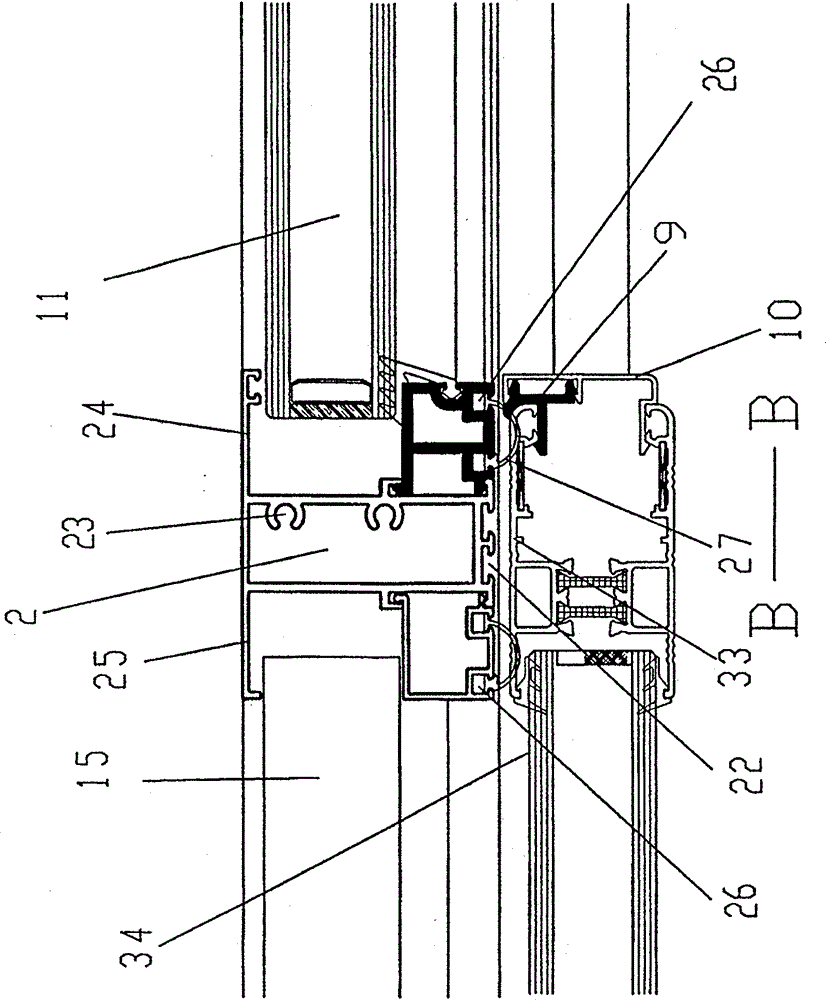

[0047] Below in conjunction with accompanying drawing concrete description embodiment: Please refer to Figure 1 to Figure 36 , the basic implementation mode of energy-saving aluminum-plastic sliding window is based on the aluminum-plastic broken bridge window frame 1, the window sash profile 3, and the aluminum alloy middle profile 2, which are different from the existing types of doors and windows, and are equipped with plastic materials of corresponding structures. Fixed glass bead 5, aluminum alloy gauze fan bead 4, sealing strips 1, 2, and 3 (6, 7, 8) of different shapes, and a cover 10 snap-fitted with heat-insulating plastic profiles 9 are assembled. One, two, three, six (6, 7, 8, 27) etc. play the role of sealing and covering heat insulation and can be replaced, forming a relative cooperation between the push-pull fan 3 and the opening and closing of the fixed glass 11, and the aluminum profile is covered by a good heat insulation performance. Non-metallic materials ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap