Engineering percussion drill

A percussion drilling rig and engineering technology, which is applied to percussion drilling, reciprocating drilling rigs, drilling equipment, etc., can solve the problems of time-consuming hoisting operations and unsafe hidden dangers, and achieve the effect of single-machine operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

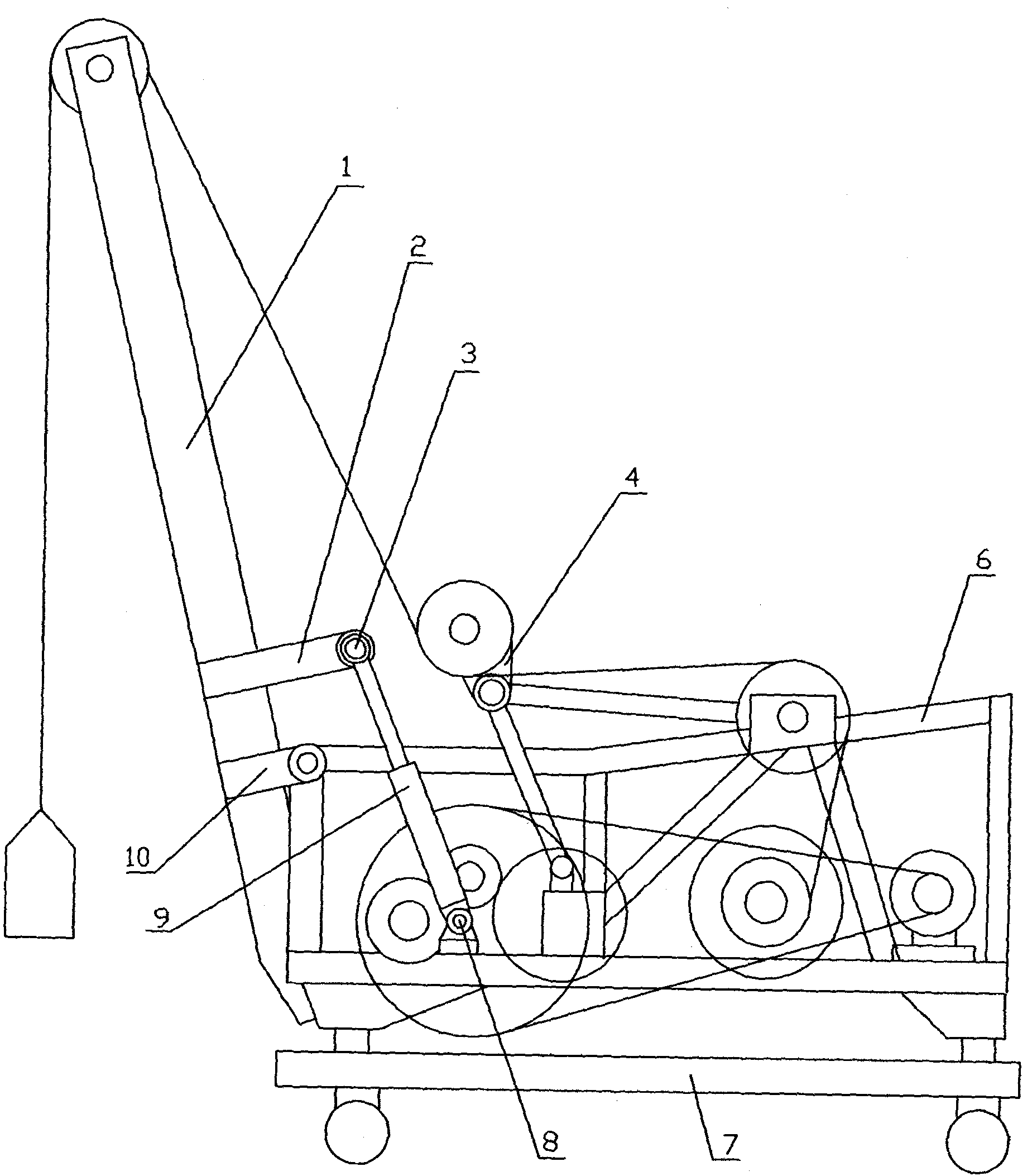

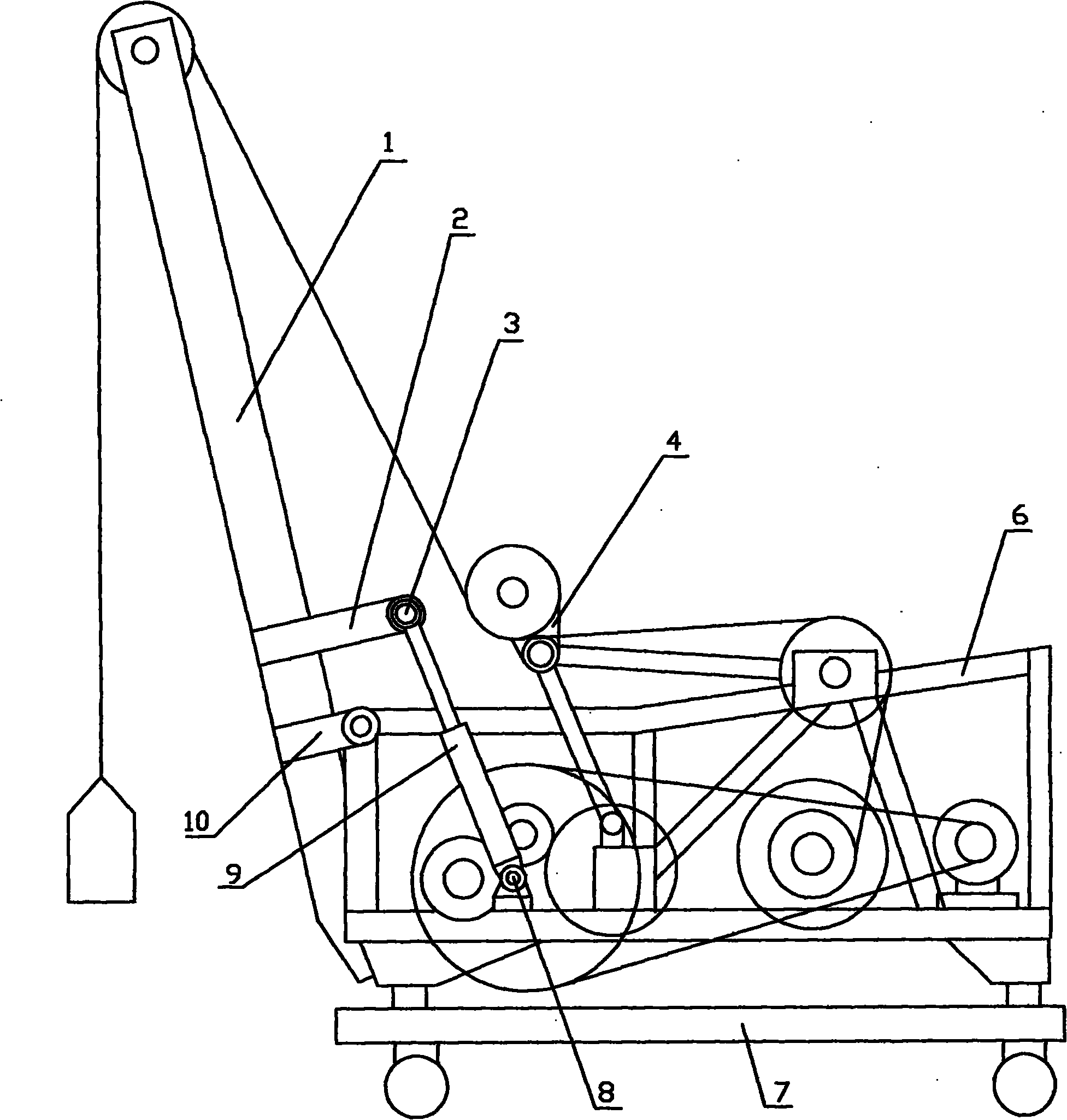

[0008] The structure of the present invention is driven by the underframe (7), the frame (6), the motor, the transmission mechanism, the front reel, the rear reel, the main reel, the impact assembly (4), the sky beam mast (1 ), an impact drill bit, a steering plate (10) is fixed on the sky beam mast (1), and the steering plate (10) is hinged with the front end frame of the frame (6) through a hinge pin, and it is characterized in that: (1) Two rectangular hoisting plates (2) on the left and right are respectively fixed in parallel above the turning plates (10) on both sides, and a splicing joint is fixed in the corresponding hole at the rear end of the two rectangular hoisting plates (2) protruding from the mast (1) Front axle pin (3); the piston rod front end of a hydraulic oil cylinder (9) is fixed with axle sleeve, and this axle sleeve moves and fits in the outer circle of front axle pin (3) middle part, and hydraulic oil cylinder (9) rear seat is provided with for The rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com