Follow-up reversing mechanism and follow-up reserving method

A reversing mechanism and follow-up technology, applied in mechanical equipment, fluid pressure actuators, servo motors, etc., can solve problems such as increasing structural complexity, avoid oil pipe fatigue, increase functions, and improve safety and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

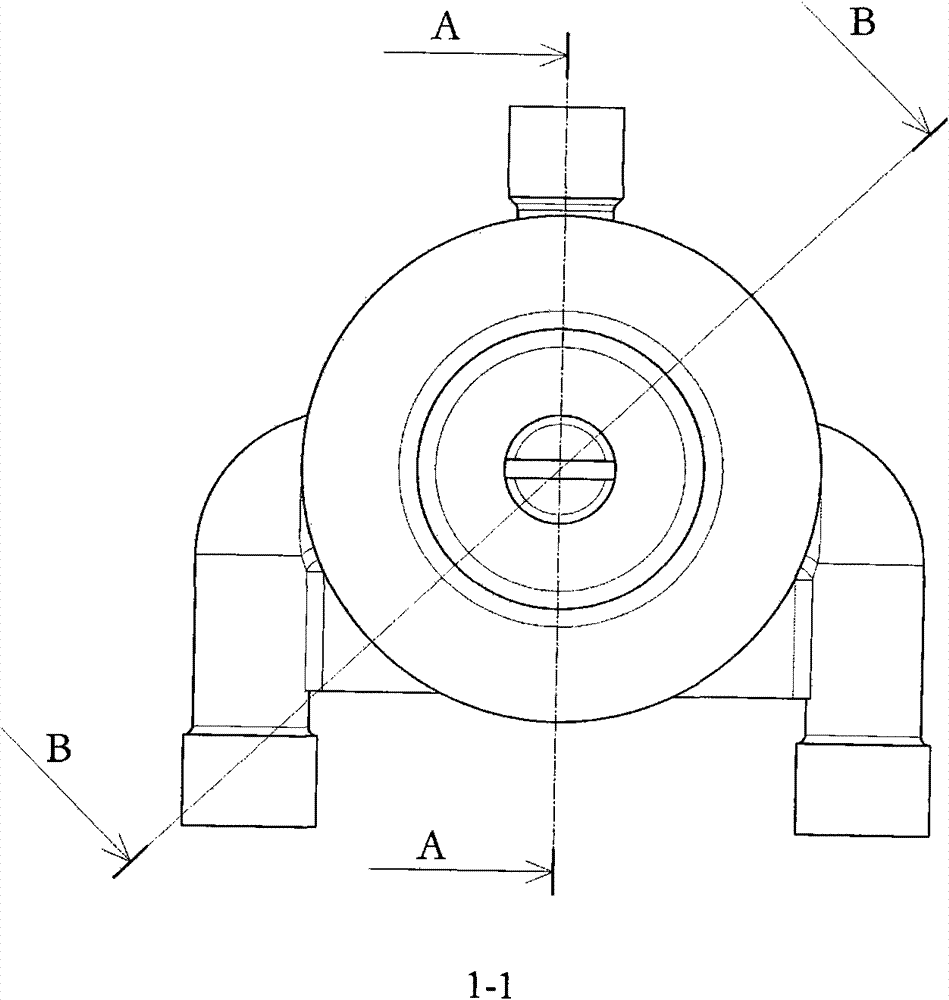

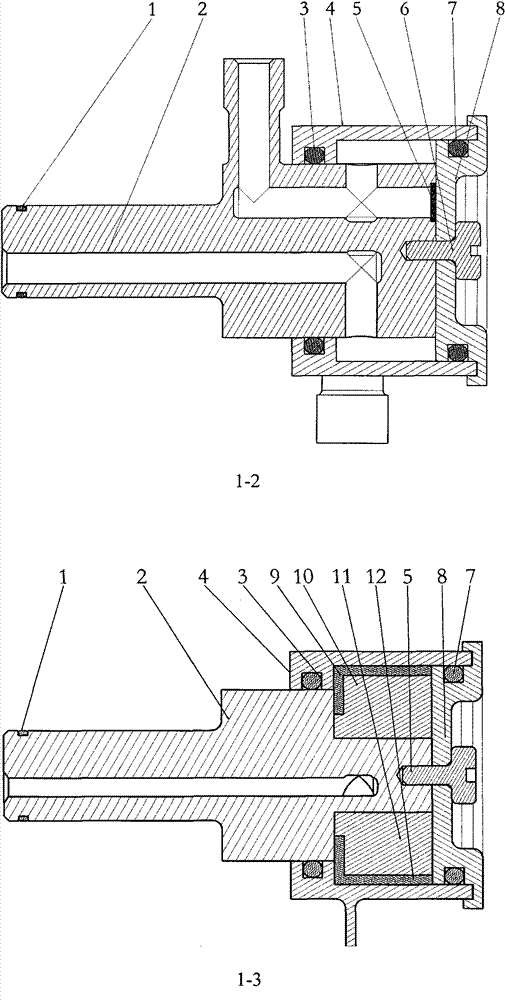

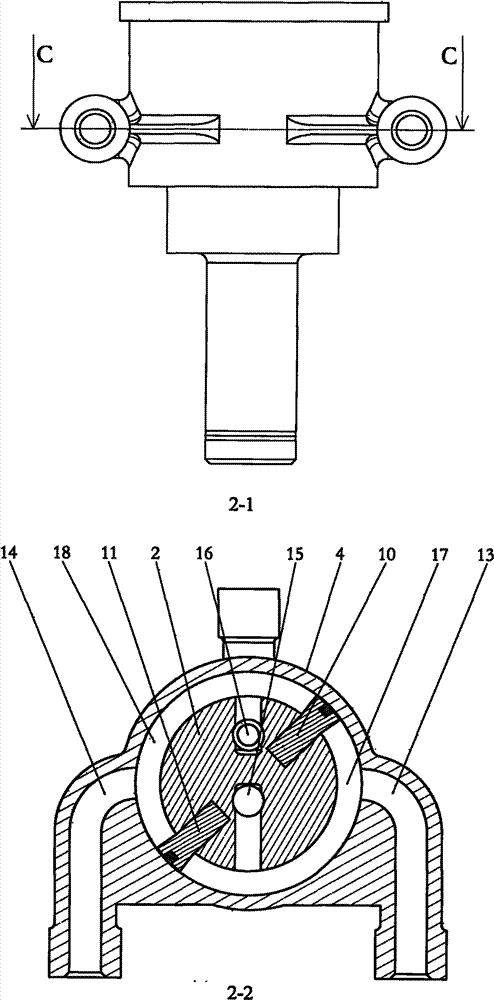

[0015] Follow-up rotary valve type reversing valve mechanism and installation layout are attached figure 1 , 2 , 3 shown. The working principle of the present invention is briefly described here.

[0016] The inside of the pressure-resistant housing 4 is a cavity. The rear end of the rotary valve core 2 extends into the pressure-resistant housing 4 and is fixedly connected with the cover 8 through bolts 6. The connection between the rotary valve core 2 and the front end of the pressure-resistant housing 4 The sealing ring 3 is in sealing contact, and the third sealing ring 7 is in sealing contact between the mouth cover 8 and the rear end of the pressure-resistant housing 4; an annular cavity is formed between the rotating valve core 2 and the pressure-resistant housing 4; it is fixed on the rotating valve core The first sub-cavity key 10 and the second sub-cavity key 11 on the 2 divide the annular cavity between the rotary valve core 2 and the pressure-resistant housing 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com