Single outstretch pole magneto-rheological damper with annular piston

A magneto-rheological damper and annular piston technology, which is applied in the direction of vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problems of shortening the effective stroke of the piston and occupying length and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

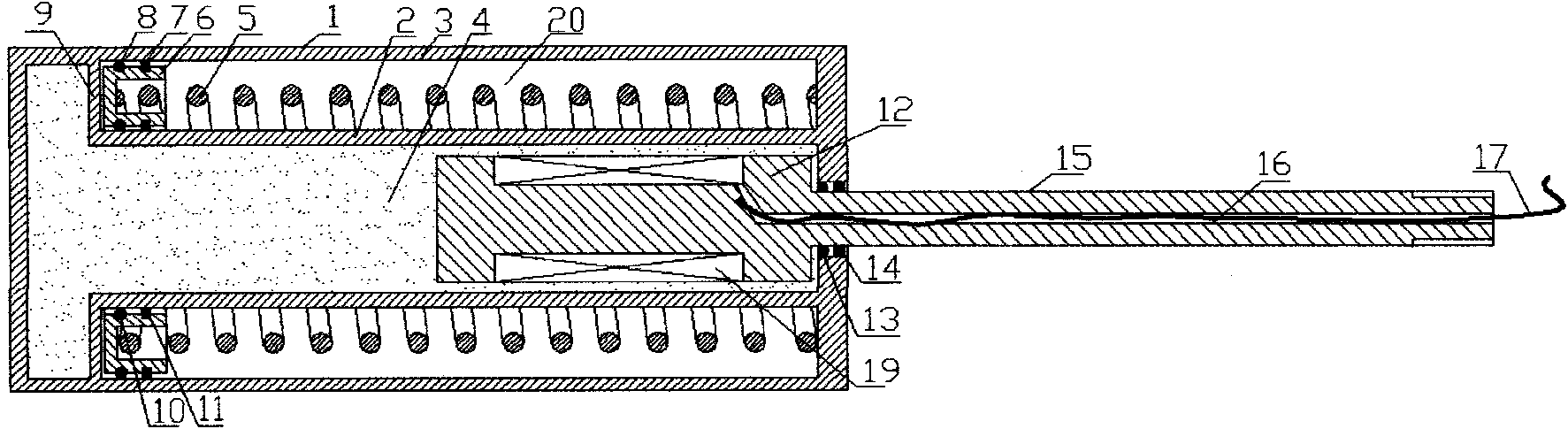

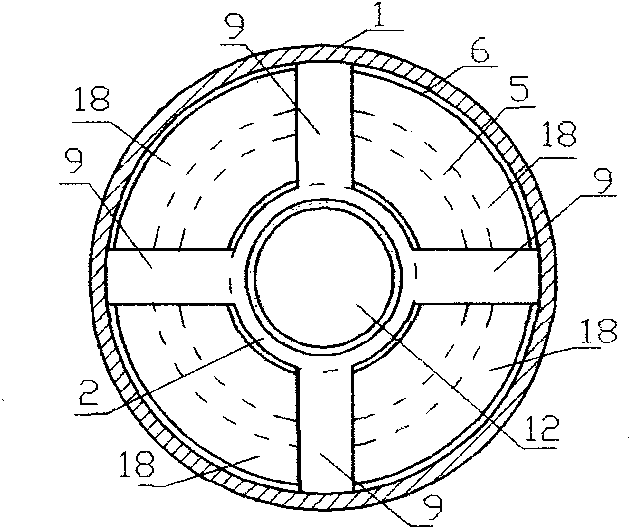

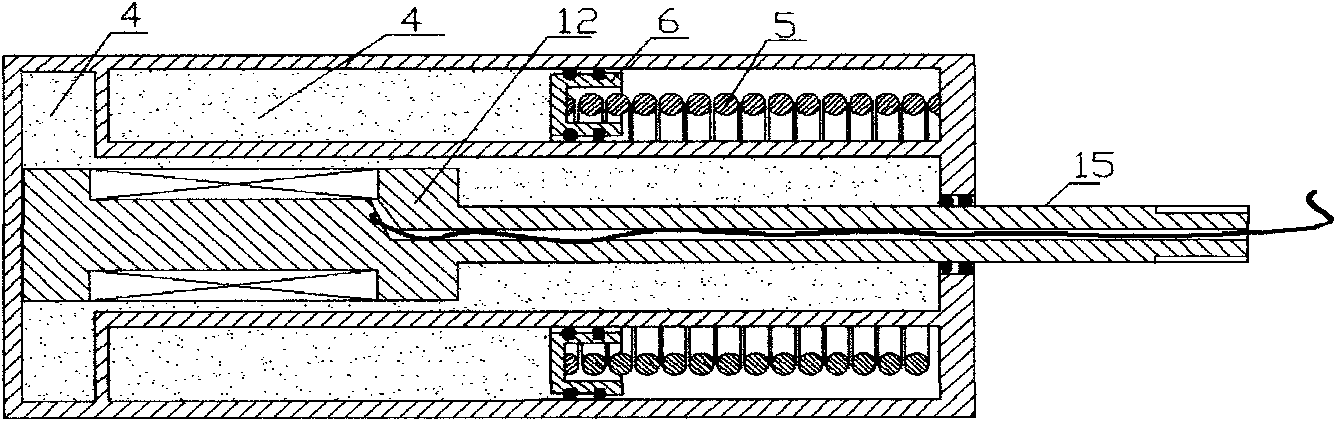

[0013] see figure 1 with figure 2 , the working cylinder 1 of the single-rod magnetorheological damper with annular piston has an inner and outer two-layer structure, wherein, the inner layer 2 of the working cylinder 1 has a piston 12, the middle part of the piston 12 is wound with a coil 19, and one end of the piston 12 is fixed Piston rod 15 is arranged, and piston rod 15 stretches out from one end of working cylinder 1 through sealing ring 13 and bearing 14, and the wiring terminal 17 of coil 19 is drawn through the center through hole 16 of piston rod 15; The inner layer 2 of working cylinder 1 and An annular piston 6 is installed in the annular cavity 20 between the outer layers 3, a sealing ring 8 and a positioning ring 7 are arranged on the outer circumference of the annular piston 6, and a sealing ring 10 and a positioning ring 11 are arranged on the inner circumference of the annular piston 6. A spring 5 is installed in the piston 6; a hole 18 for the flow of magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com