Centralized driving LED colored lantern lighting device

A centralized drive and lighting device technology, applied in the field of lighting, can solve the problems of inconvenient adjustment of brightness and color, low power utilization efficiency, and large number of drivers, etc., to reduce overall complexity, high power utilization efficiency, and lower technical requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

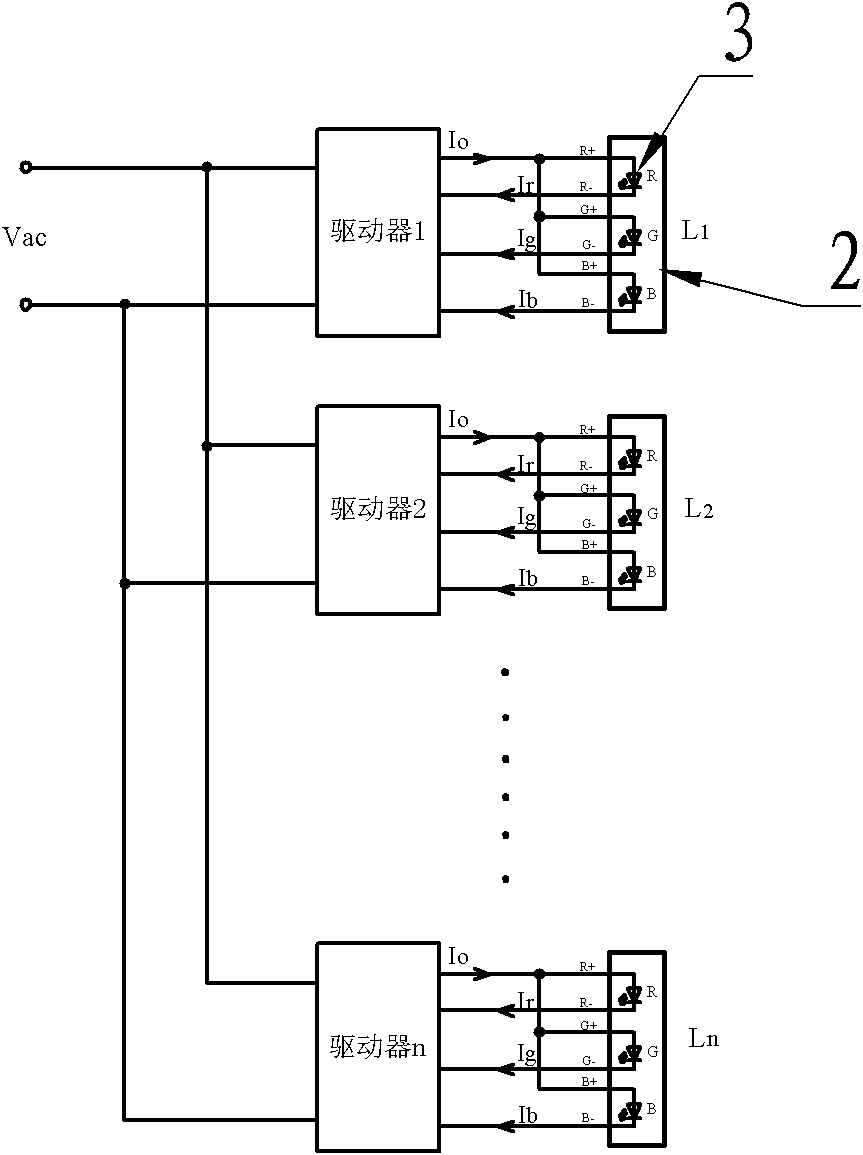

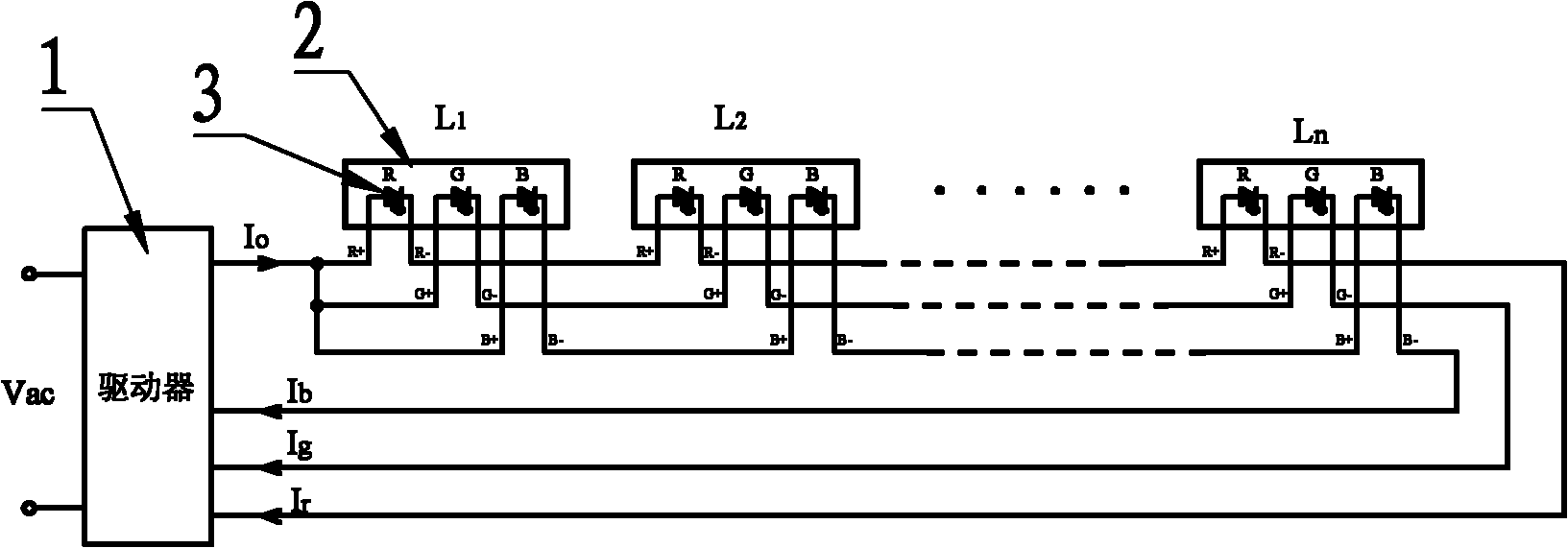

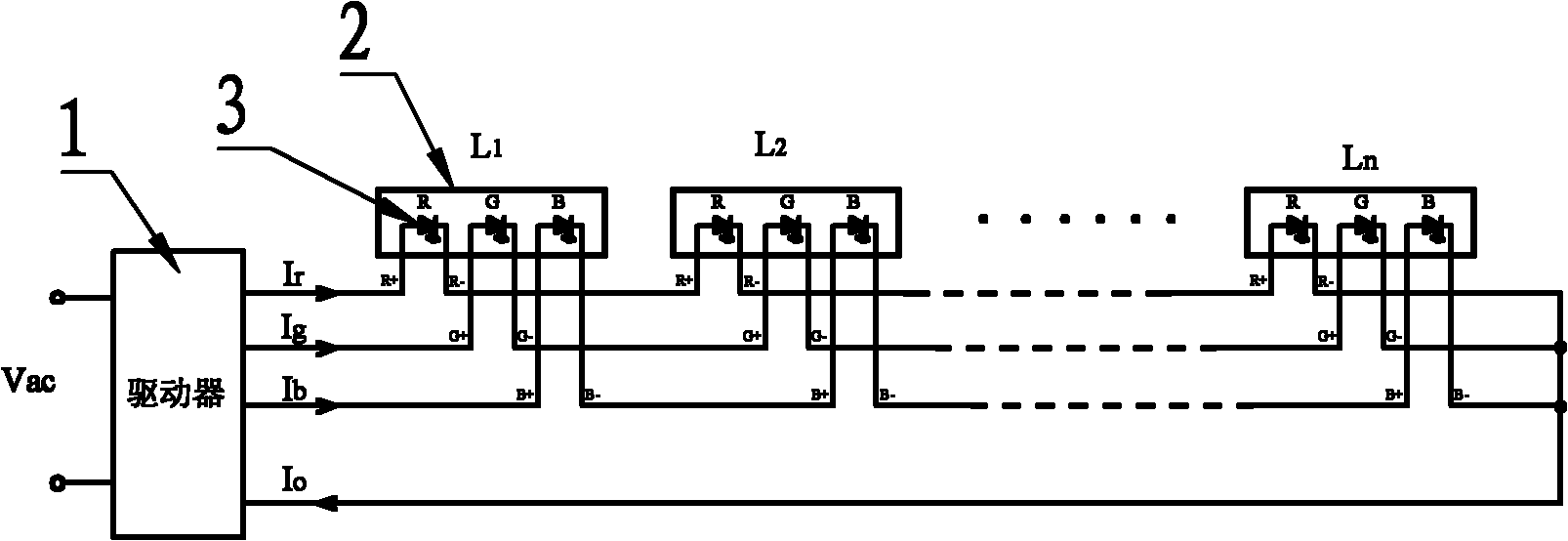

[0035] refer to figure 2 , the lighting device for intensively driving LED colored lights of the present invention includes a driver 1 and at least two LED colored lights 2, the LED colored lights 2 in this example are RGB colored lights, represented by L, there are N LED colored lights 2 , then use L1, L2,..., Ln to represent. There are R light source tubes, G light source tubes and B light source tubes in the RGB color lamp L, each light source tube 3 is provided with at least one, and the light source tubes 3 of the same color of each LED color lamp 2 are connected in series to form a corresponding series branch. Each series branch is driven by the same driver 1, and the two ends of each series branch are connected to the two output terminals of the driver 1.

[0036] Wherein, the number of each light source tube 3 in each LED lantern 2 may be one, or at least two. If each color light source tube 3 in each LED color lamp 2 is provided with one, the series branches are re...

Embodiment 2

[0044] Embodiment 2 is basically the same as Embodiment 1, the difference is that the LED colored light 2 in this example is a WIED colored light, and the WIED colored light is not only provided with the same RGB light source tube as in Embodiment 1, but also has a W light source tube .

[0045] Such as Figure 5 As shown, the same W light source tubes are connected in series to form a W series branch. The positive end of the W series branch is connected to the output high potential end of driver 1, and the negative end is connected to the output low potential end of driver 1. The current from the output low potential end Driven by Iw, it is a common positive terminal connection mode, and the output current Io of the high potential terminal is the sum of Ir, Ig, Ib, and Iw.

[0046] Such as Figure 6 As shown, it is the connection mode of the common ground terminal. The positive terminal is connected to the output high potential terminal of driver 1, and the negative termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com