Energy-saving air power source system of wood drying device

An aerodynamic, wood drying technology, applied in the direction of drying gas arrangement, humidity control wood, wood processing appliances, etc., can solve the problems of short service life of fans, high power consumption of motors, low efficiency of fans, etc. The effect of low motor power consumption and power consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

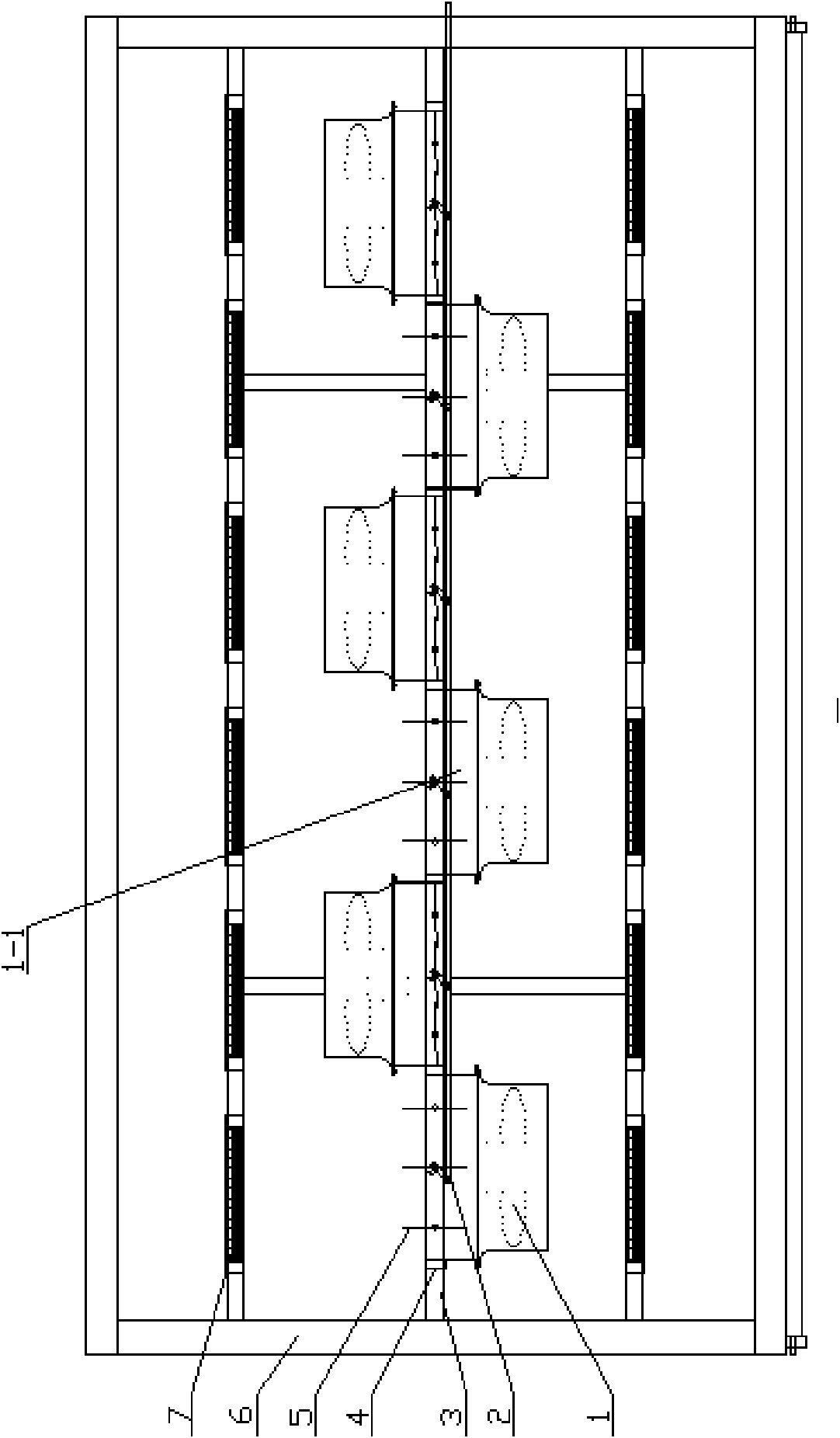

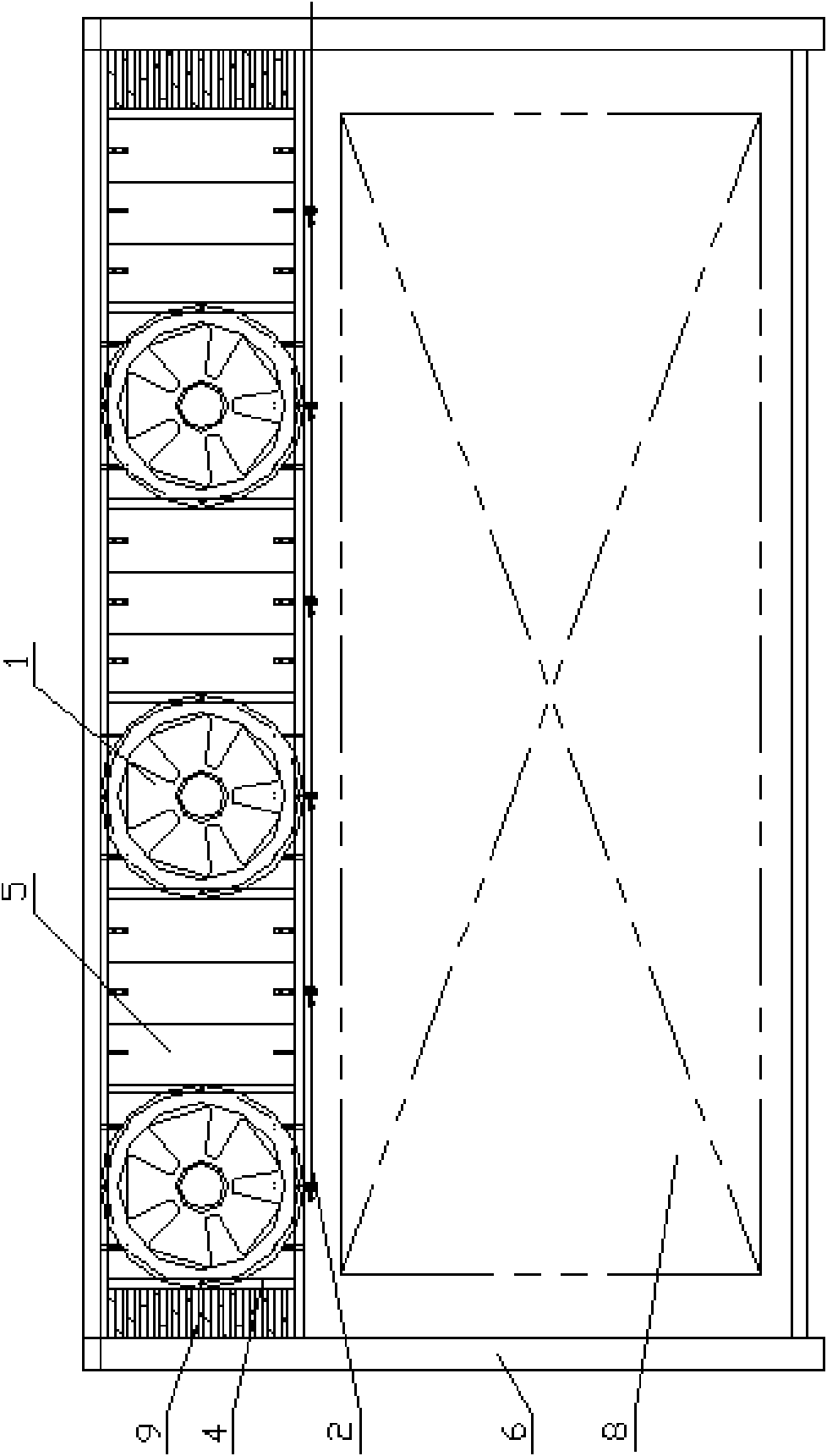

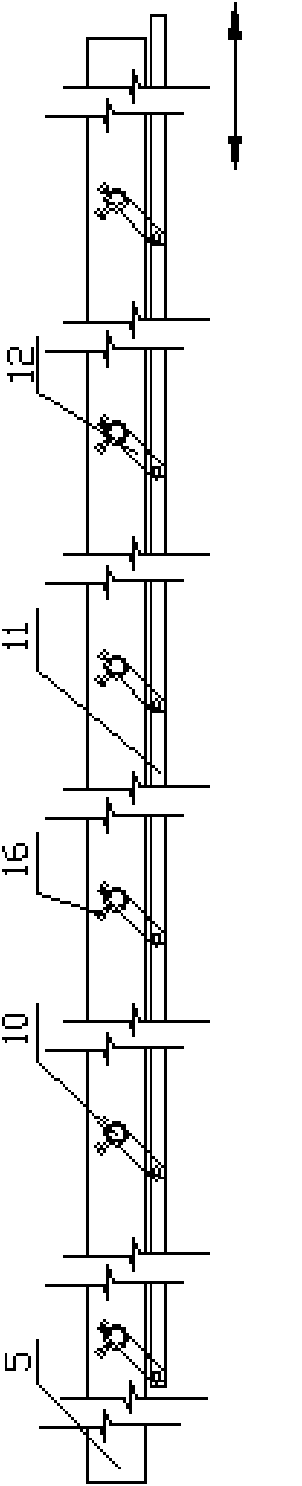

[0008] Specific implementation mode one: combine Figure 1 to Figure 9 Describe this embodiment, the aerodynamic source system described in this embodiment includes a plurality of fans; the aerodynamic source system also includes a bracket 3, a plurality of louvers, a shutter control mechanism 2 and a plurality of fan baffles 9; It is a one-way axial flow fan 1, and each louver is made up of a plurality of louver blades 5, a louver frame 4 and a synchronous linkage mechanism; the synchronous linkage mechanism consists of a plurality of first linkage handles 13, a plurality of second linkage handles 14 and The first linkage rod 15 is formed; a plurality of louver blades 5 are arranged in the louver frame 4 along the width direction of the drying chamber 6, and each louver frame 4 is fixed on the support 3, and the support 3 is fixed on the length direction of the drying chamber 6. In the drying chamber 6, each louver blade 5 in each louver is fixedly connected to one end of a f...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 and figure 2 To illustrate this embodiment, the bracket 3 in this embodiment is arranged on the central axis of the drying chamber 6 in the longitudinal direction, and the plurality of louvers are arranged in a line and located on the central axis of the drying chamber 6 in the longitudinal direction. The axial flow fan 1 is arranged in a staggered manner relative to the support 3 . This kind of layout causes different airflow resistances due to the wall distance and airflow stroke difference between the inlet and outlet of the unidirectional axial flow fan 1 and the air outlet of the drying chamber 6, so that the wind speed obtained at the inlet side of the timber stack is not the same. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination Figure 9 Describe this embodiment, the support 3 of this embodiment is arranged on the central axis of the drying chamber 6 in the longitudinal direction, and the plurality of unidirectional axial flow fans 1 are arranged in a line on the central axis of the support 3 .

[0012] The difference between the present embodiment and the second specific embodiment is not obvious in the influence of the two layouts on the air circulation rate. The shape, size and quantity of the louver blades 5 can be adjusted and determined according to actual conditions. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com