Rubber wheel hinging type bogie for guiding trolleybus and guiding trolleybus

An articulated, bogie technology, applied to the steering mechanism, steering mechanism, vehicle components and other directions of front and rear tandem vehicles, can solve problems such as being no longer suitable, difficult to lower the floor, etc., to reduce the accident rate, improve steering performance, The effect of improving power utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

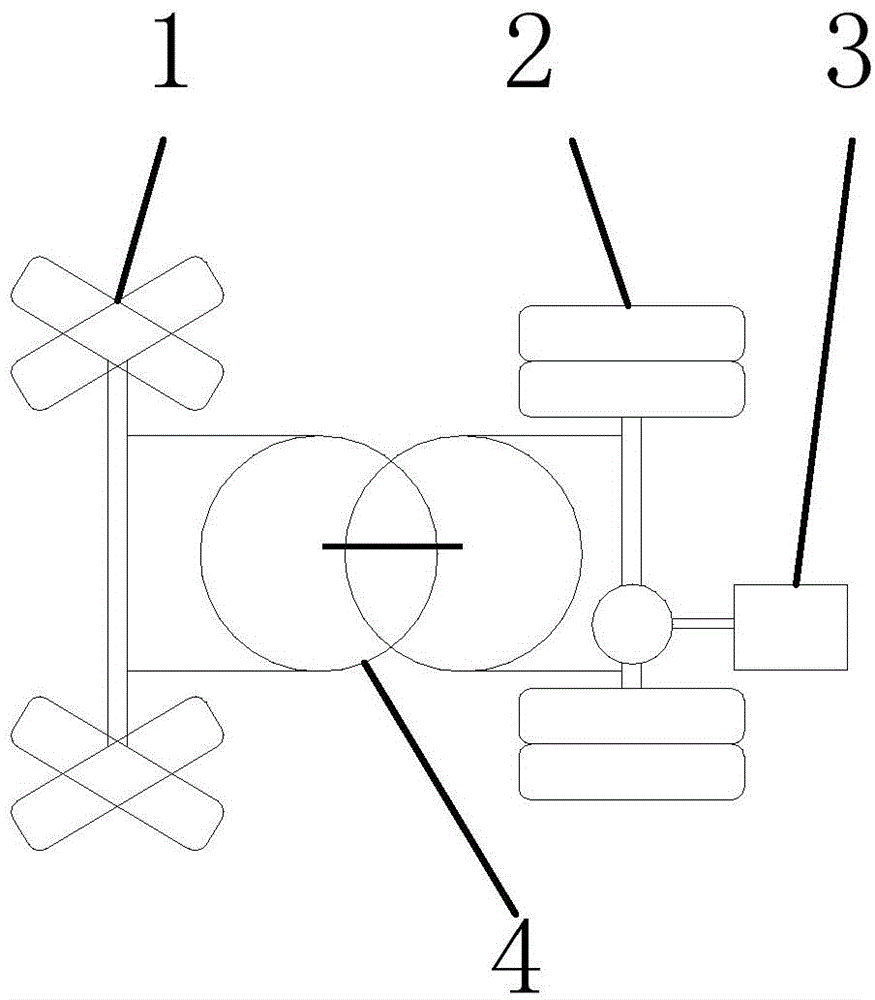

[0028] Embodiment 1: as figure 1 As shown, the rubber-tyred articulated bogie for trackless guided trams of the present invention can be a power bogie, which includes an active steering axle assembly 1, and a power shaft biased by a power input port that is carried by twin tires or single tires. Assembly 2, drive motor 3 and hinge assembly 4 using double joints, drive motor 3 is connected to the final reducer and differential in the biased power input port, and an angle sensor is installed at each joint point in the hinge assembly 4 to Measure the angle of the hinge.

[0029] In this embodiment, an angle sensor is installed on the active steering axle assembly 1 on the bogie to detect the wheel deflection angle.

[0030] In this embodiment, all wheels are equipped with wheel speed sensors to detect the wheel speed.

Embodiment 2

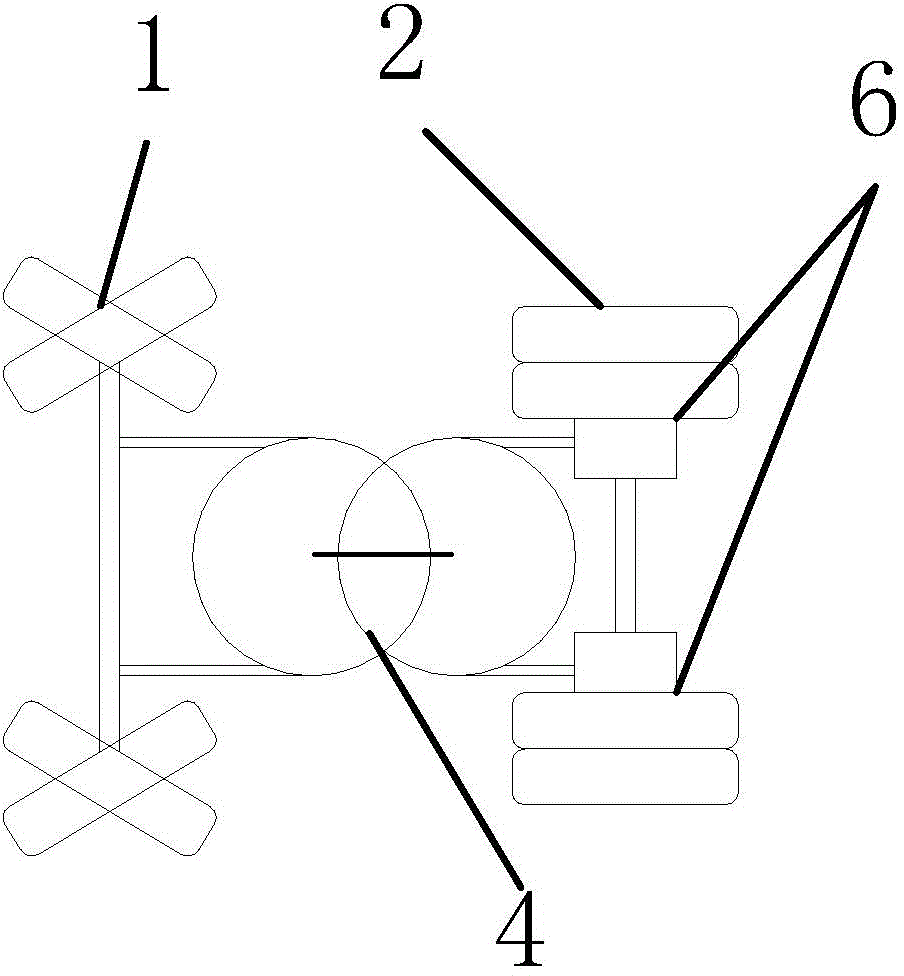

[0031] Embodiment 2: as figure 2 As shown, the rubber-tyred articulated bogie for trackless guided trams of the present invention can be a power bogie, which includes an active steering axle assembly 1, a power axle assembly 2 that is carried by twin tires or a single tire, wheel rims / The hub motor 6 and the hinge assembly 4 using double joints, the wheel edge / hub motor 6 is connected with the power shaft assembly 2 and drives the power shaft assembly 2 . An angle sensor is installed at each joint point in the hinge assembly 4 to measure the angle of the hinge.

[0032] In this embodiment, an angle sensor is installed on the active steering axle assembly 1 on the bogie to detect the wheel deflection angle.

[0033] In this embodiment, all wheels are equipped with wheel speed sensors to detect the wheel speed.

Embodiment 3

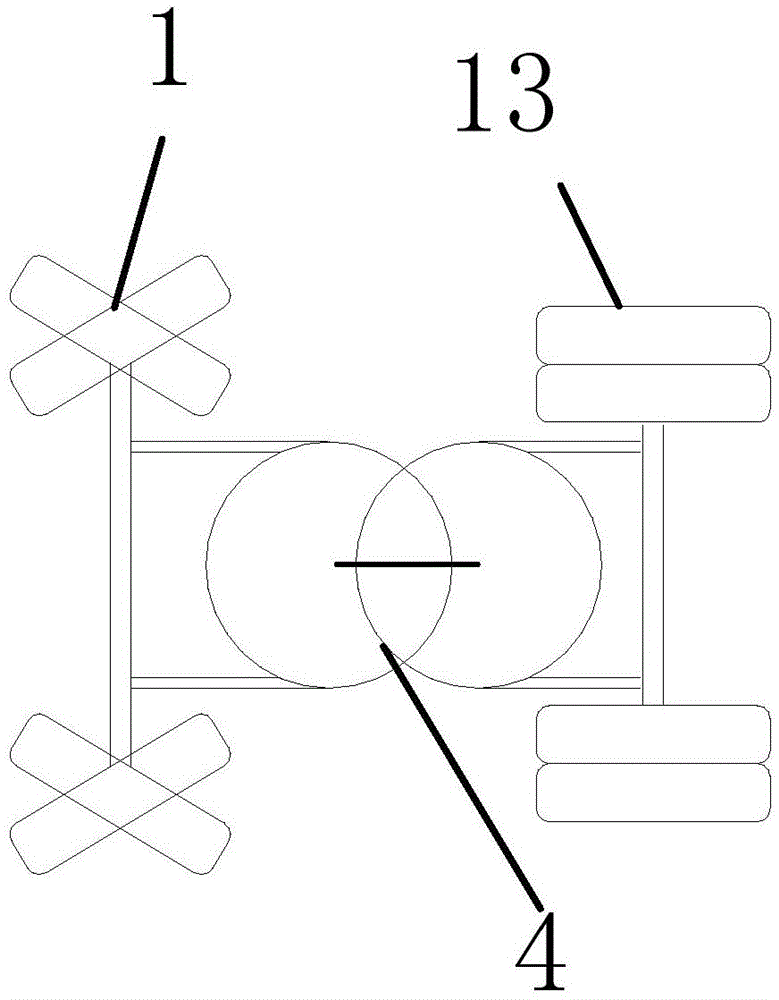

[0034] Embodiment 3: as image 3 As shown, the rubber-tyred articulated bogie for trackless guided trams of the present invention can be a non-power bogie, which includes an active steering axle assembly 1, a non-steering axle assembly 13 that adopts double tire load or single tire load, and adopts The hinge assembly 4 of double joint points, in the hinge assembly 4, an angle sensor is installed at each joint point to measure the angle of the hinge.

[0035] In this embodiment, an angle sensor is installed on the active steering axle assembly 1 on the bogie to detect the wheel deflection angle.

[0036] In this embodiment, all wheels are equipped with wheel speed sensors to detect the wheel speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com