New method for measuring screw pitch of propeller blades

A technology of a propeller and a new method is applied in the field of image-based propeller blade pitch measurement, which can solve the problems of wear measurement, heavy workload, affecting the accurate measurement of propeller blades, etc., and achieve the effect of reducing production costs and shortening processing cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, illustrate the new method of the propeller blade pitch measurement based on image method that the present invention proposes, its technical principle and specific implementation method are as follows:

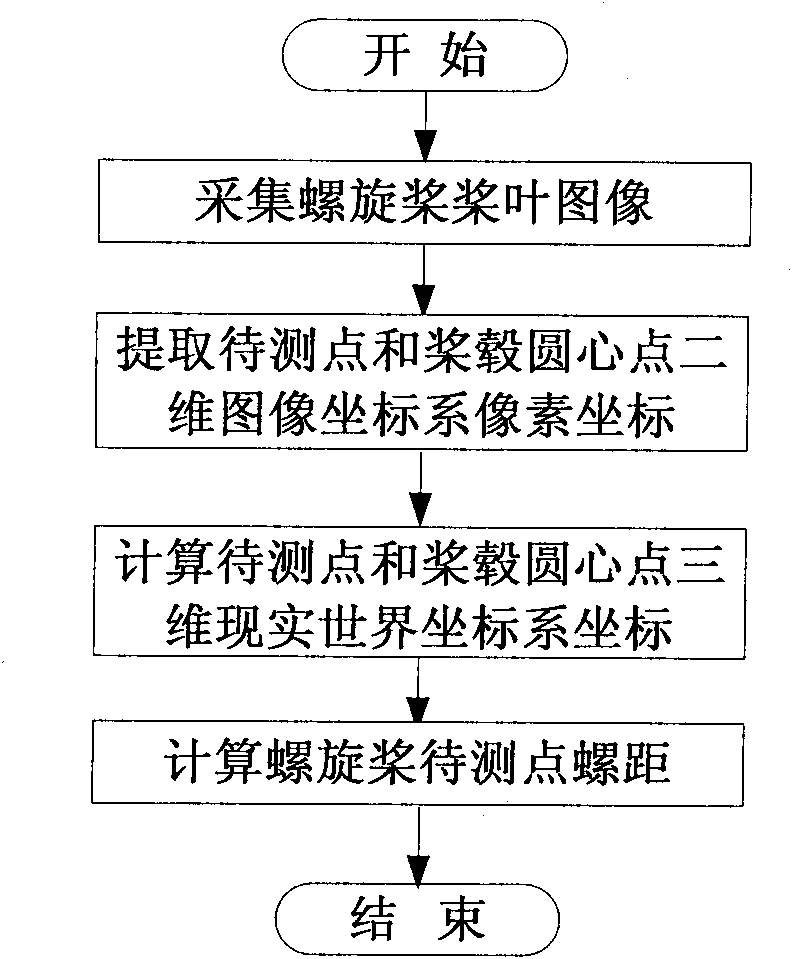

[0022] figure 1 It is the main step of the new method of propeller blade pitch measurement. The method uses images to measure. First, the image of the propeller blade is collected, and then the pixel coordinates of the two-dimensional image coordinate system of the point to be measured and the center point of the propeller hub are obtained. And according to the theory of binocular vision, the coordinates of the three-dimensional real world coordinate system of the point to be measured and the hub center point are calculated, and the pitch of the propeller blade is calculated on this basis. The present invention can realize the measurement of propeller blade pitch according to this step.

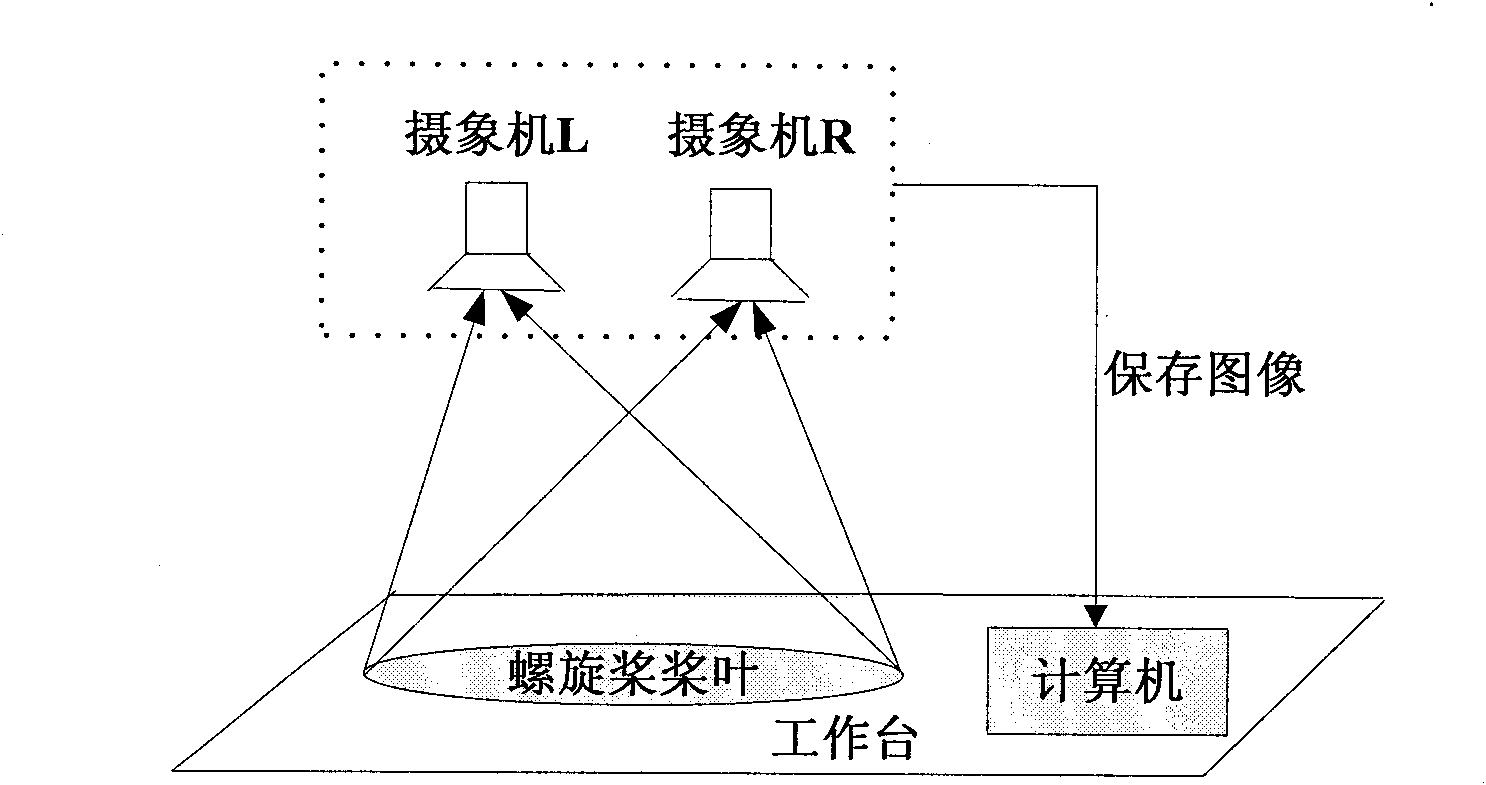

[0023] figure 2 It is a schemati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com