3D imaging method and system based on LED array common lens TOF depth measurement

An LED array and depth measurement technology, applied in optical components, optics, instruments, etc., can solve the problems of slow acquisition of depth images, poor alignment accuracy of depth images and two-dimensional images, etc., and achieve strong resistance to ambient light interference, Get fast, high-resolution results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

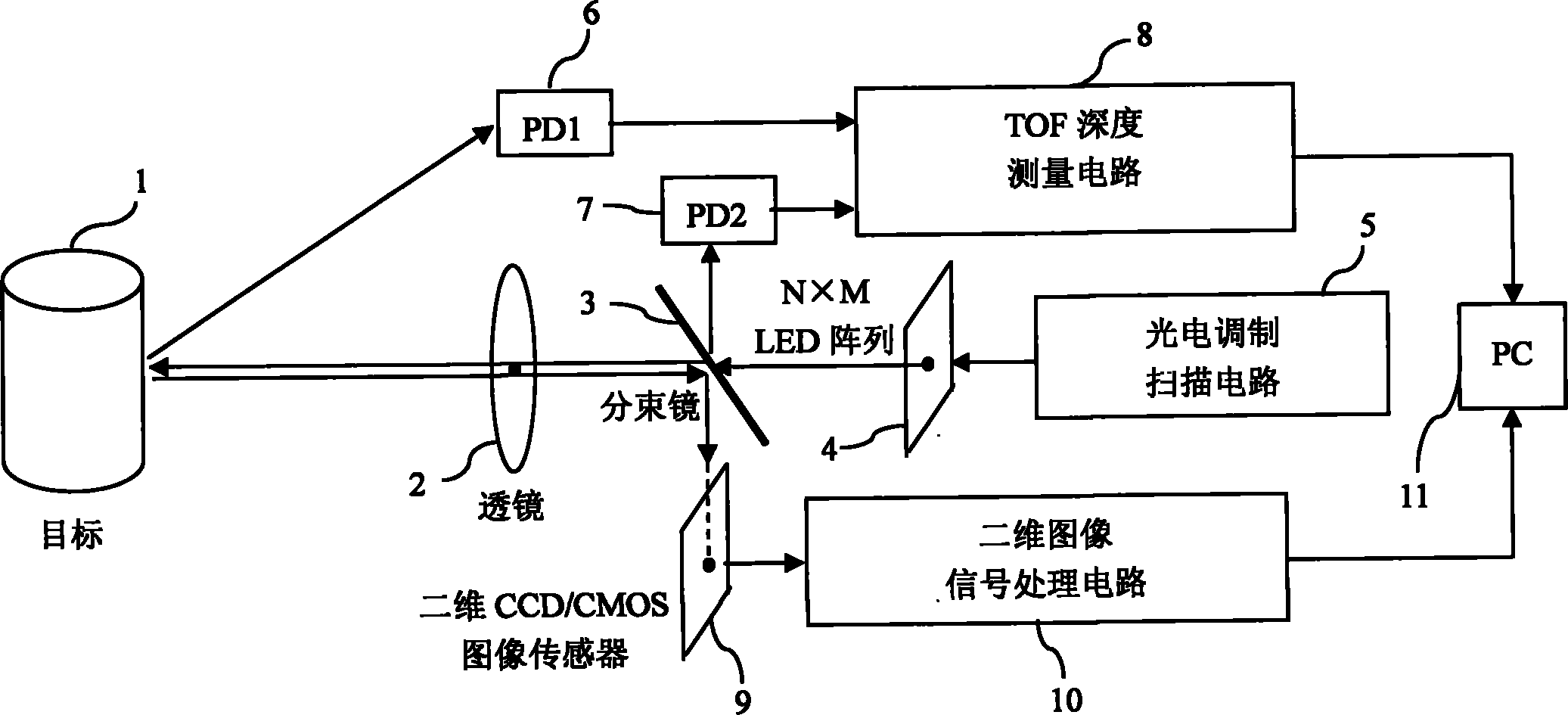

[0027] In this embodiment, the three-dimensional imaging method based on LED array common lens TOF depth measurement is carried out as follows:

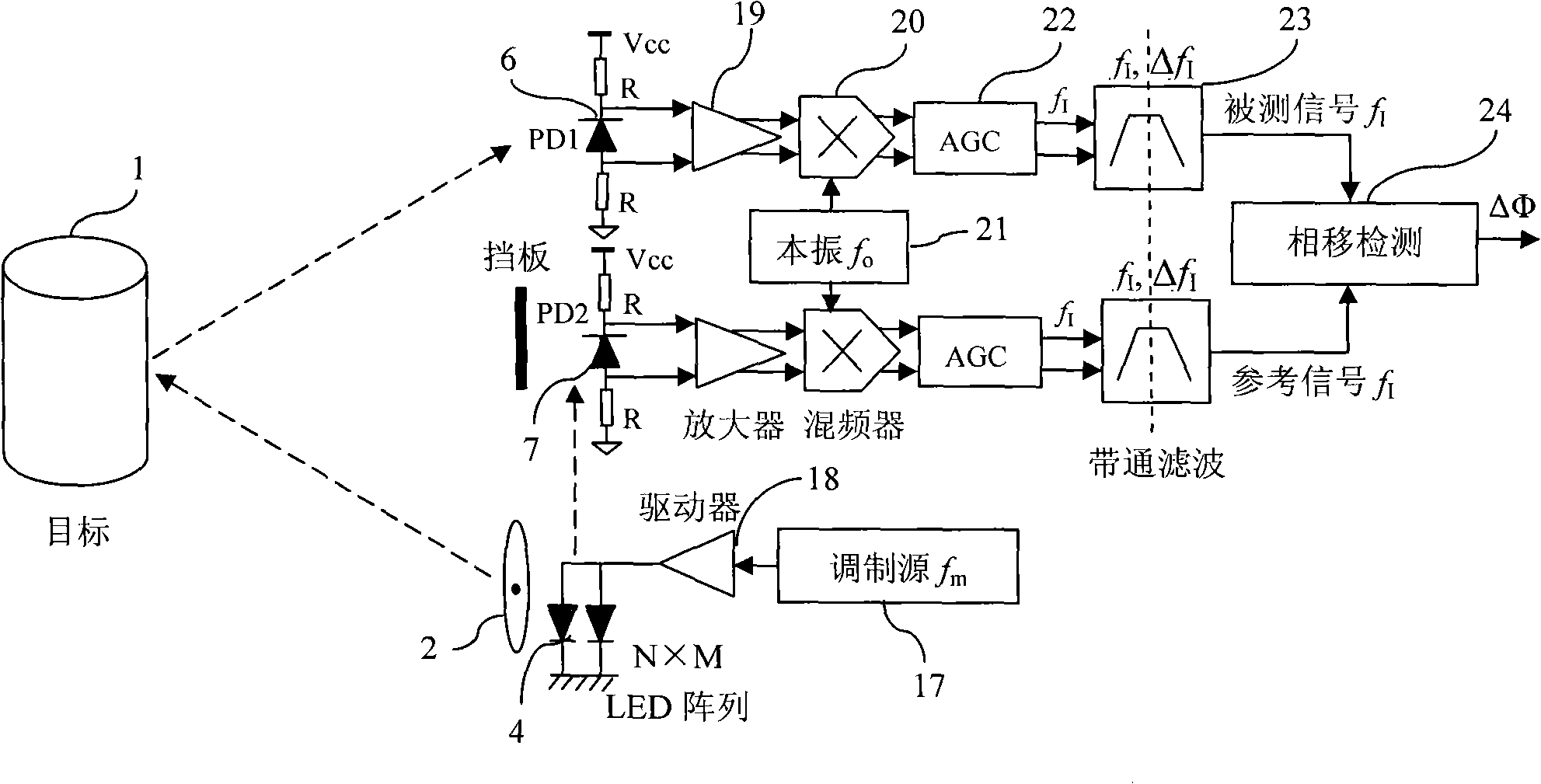

[0028] 1. A two-dimensional LED array modulated by optical power is used as the lighting source. Only one LED in the two-dimensional LED array is lit at a time, and the modulated light emitted by the LED is projected onto the surface of the target 1 through the projection lens. The receiver 6 receives the scattered light on the surface of the target 1, measures the round-trip time of flight TOF from the light source to the target 1, calculates the depth pixel value of the LED in the lit state according to the round-trip time of flight TOF, and completes the depth pixel value of a single LED. Measurement;

[0029] 2. Scan the entire two-dimensional LED array in time division, repeat the measurement process of the depth pixel value of a single LED, obtain all the depth pixel values of the LED and combine them to generate the depth im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com