Flat solar battery bracket

A solar cell, flat-panel technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as damage to roof structure, damage, cracks, etc., and achieve the effect of increasing contact area, prolonging service life, and strengthening homogeneity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

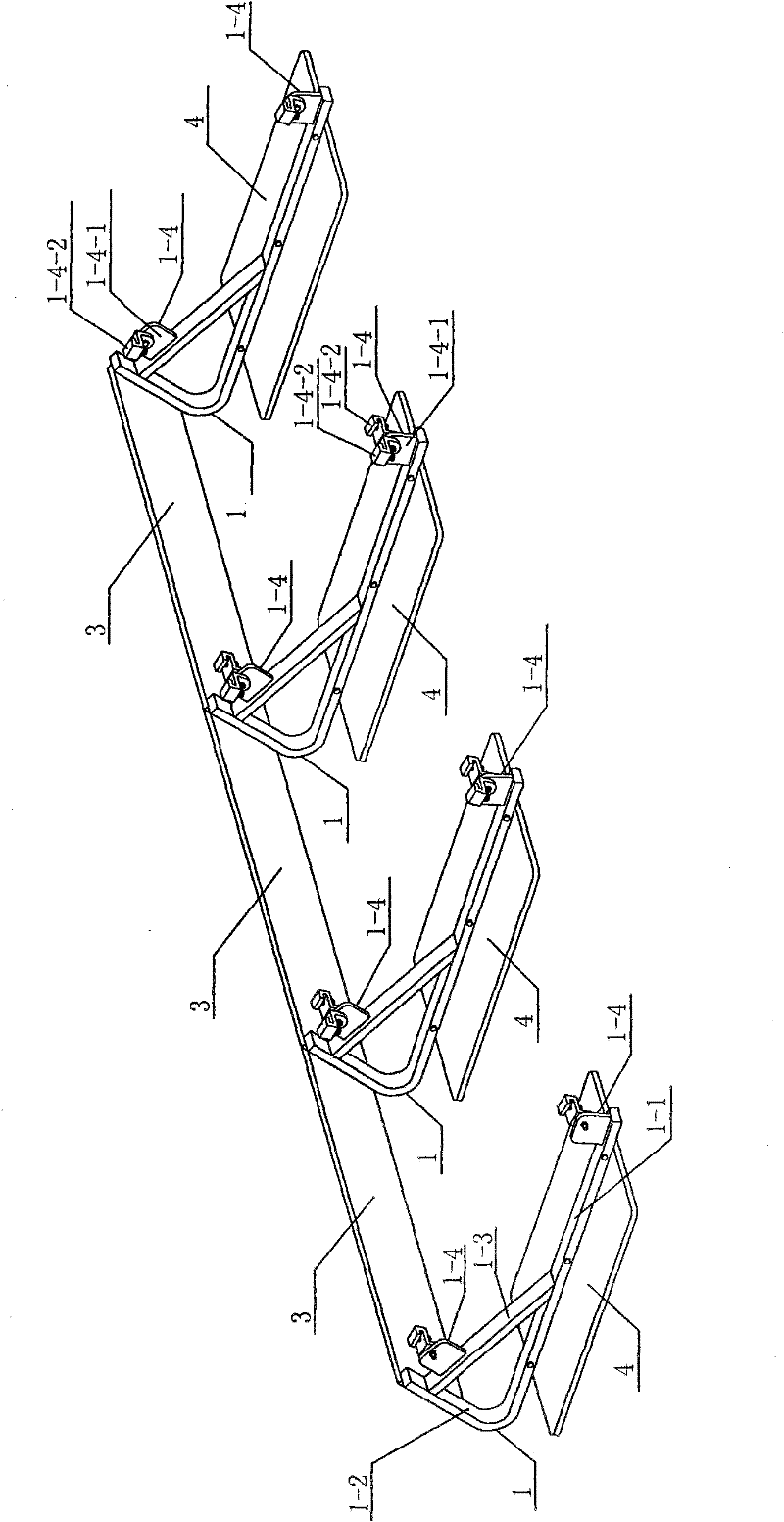

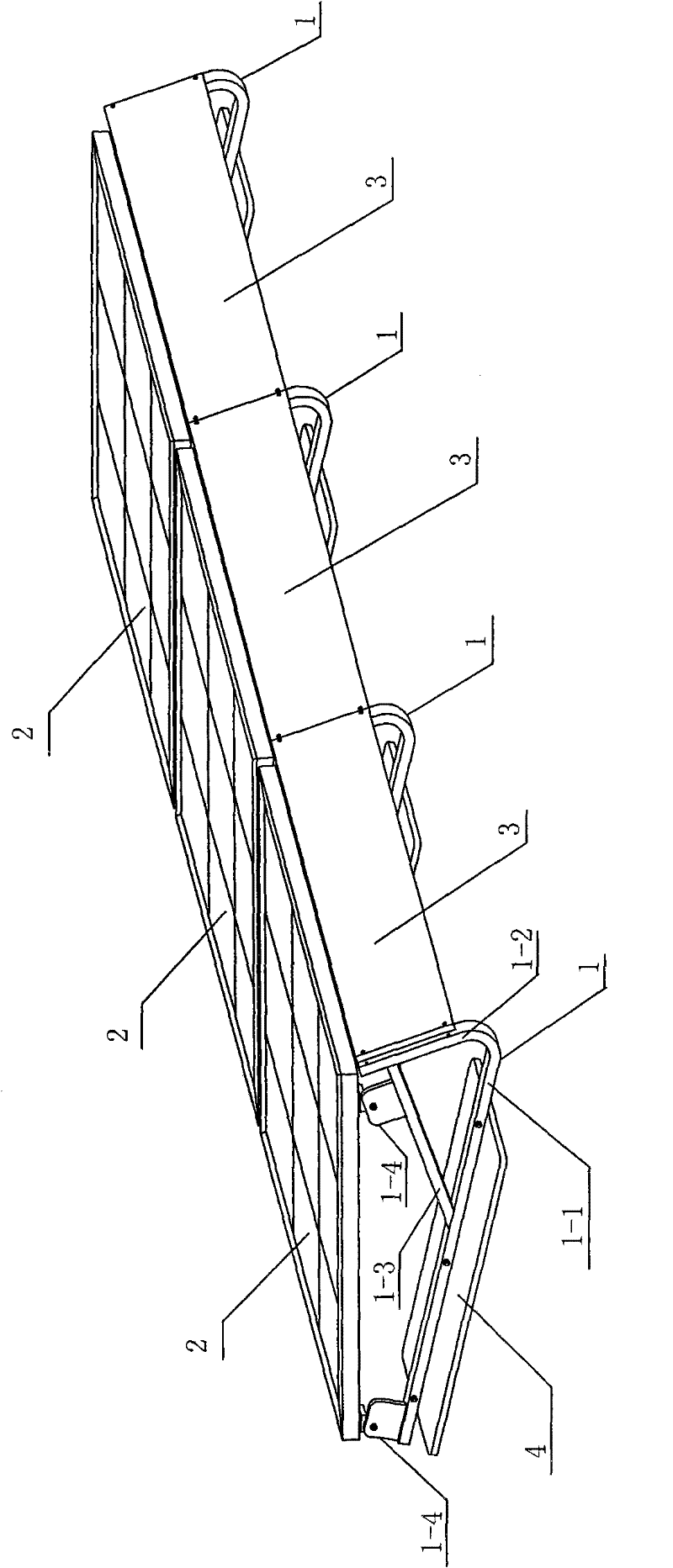

[0021] see figure 1 , figure 2 As shown, a flat-plate solar cell support, when three flat-plate solar cells need to be placed, four horizontal support feet 1 arranged side by side in the same direction are provided, and the space between two adjacent horizontal support feet 1 The spacing is the same as the width of the flat-plate solar cells 2, and each horizontal support foot 1 is composed of a horizontal beam 1-1, an oblique vertical beam 1-2, a supporting beam 1-3 and two support members 1-4, each The supporting part 1-4 is made up of a supporting seat 1-4-1 and a draw-in groove part 1-4-2. The horizontal beam 1-1 and the inclined vertical beam 1-2 are integrally formed by an aluminum profile, and the angle a between the horizontal beam 1-1 and the inclined vertical beam 1-2 is 50°. A support beam 1-3 is welded between the middle position of -1 and the middle and upper position of the inclined vertical beam 1-2, and a supporting seat 1-4-1 is welded on the end of the str...

Embodiment 2

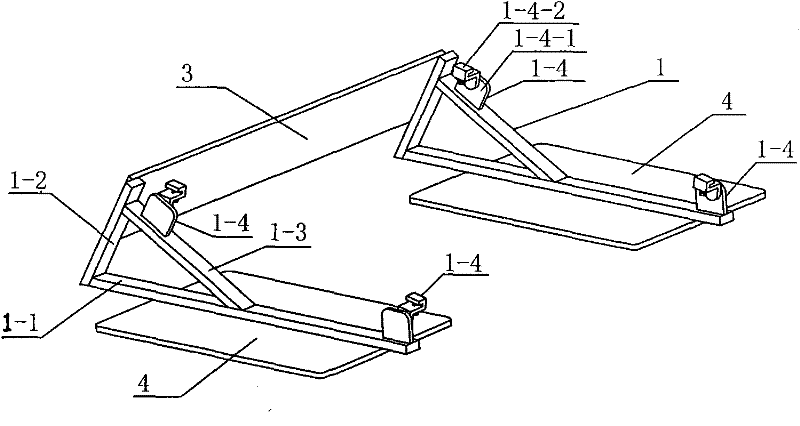

[0023] see image 3 , Figure 4 As shown, a flat solar battery support, when only one flat solar battery needs to be placed, two horizontal support legs 1 arranged side by side in the same direction can be used, and one of the two horizontal support legs 1 The distance between them is slightly smaller than the width of the flat-plate solar cell 2, and each horizontal support foot 1 is composed of a horizontal beam 1-1, an inclined vertical beam 1-2, a support beam 1-3 and two support members 1-4, Each supporting member 1-4 is made up of a supporting base 1-4-1 and a groove member 1-4-2. One end of the horizontal beam 1-1 is welded to the lower end of the inclined vertical beam 1-2, and the angle a between the horizontal beam 1-1 and the inclined vertical beam 1-2 is 40°. A support seat 1-4-1 is welded on the other end of the beam 1-1, and a supporting beam 1-4-1 is welded between the middle position of the horizontal beam 1-1 and the upper middle position of the inclined ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com