Power lithium-ion battery with heat dissipation performance

A lithium-ion battery, heat dissipation technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of high consistency requirements, poor high power performance, poor overall heat dissipation, etc. Improve electrochemical performance, increase output current, and improve the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

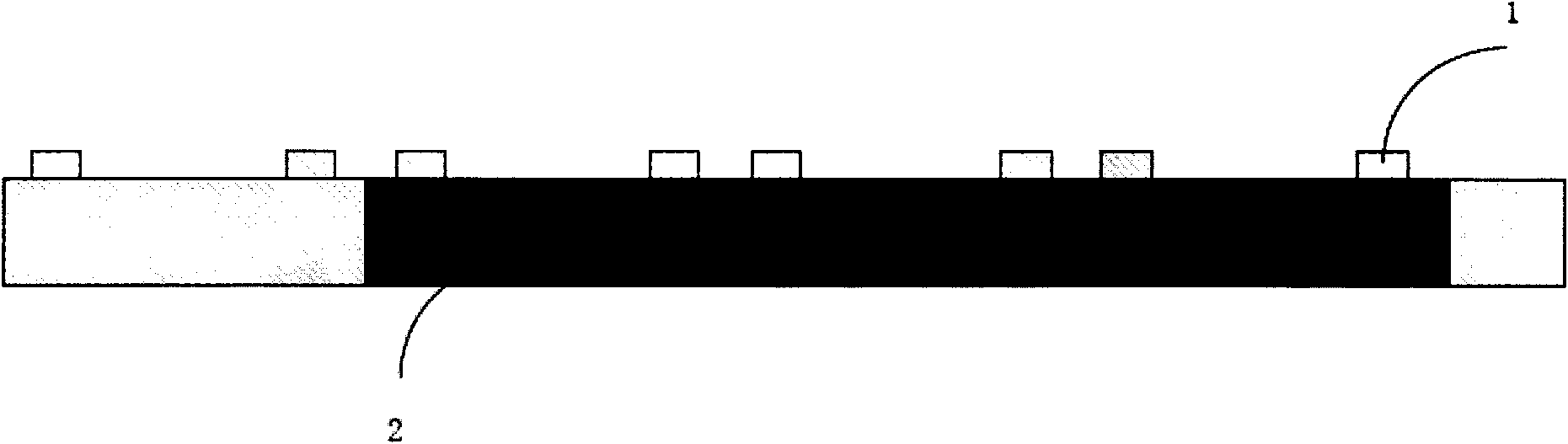

[0020] Embodiment 1, such as Figure 1 to Figure 3 As shown, the present invention provides a power type lithium ion battery with heat dissipation performance, which includes a positive pole piece 4, a negative pole piece 2 and a separator (not shown), the electrode pole piece includes a current collector and is coated on the collector. Active substance diaphragm on fluid. Wherein, the negative electrode current collector has a plurality of negative electrode extensions 1 extending in its width direction, and the positive electrode current collector has a plurality of positive electrode extensions 3 extending in its width direction. Such as Figure 4 As shown, after the positive and negative electrode pieces and the separator are wound to form the battery core 7, the extensions provided on the positive and negative current collectors are combined together to form the negative tab 5 and the positive tab 6, respectively. The positive and negative tabs are formed at the same en...

Embodiment approach 2

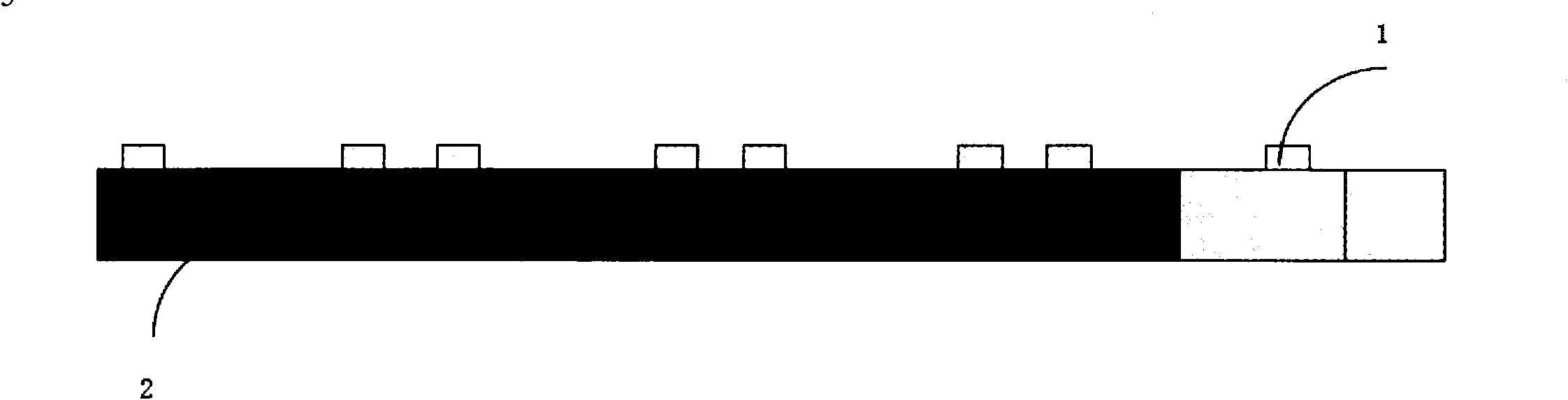

[0023] Implementation mode two: if Figure 5 As shown, as another mode of the power lithium-ion battery with heat dissipation performance of the present invention, the positive and negative pole tabs are formed at both ends of the battery, and the basic structure of the positive and negative poles is the same as that of Example 1, except that the pole pieces Dimensions vary.

[0024] In this embodiment, the theoretical design capacity of the cell is 3.5Ah, and Li 4 Ti 5 o 12 As the negative electrode active material, the negative electrode active material, the conductive agent, the binder, etc. are made into a negative electrode slurry according to a certain ratio, and coated on the negative electrode current collector to make the negative electrode sheet; the positive electrode active material of the battery adopts composite metal oxide , such as LiMn 2 o 4 , LiNiCoMnO 2 etc., positive electrode active material and binder, conductive agent, etc. are made into positive e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com