Tea making machine

A tea making machine and tea technology, applied in beverage preparation devices, household utensils, applications, etc., can solve general, unavoidable, general tea taste problems, etc., and achieve the effect of high degree of automation and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

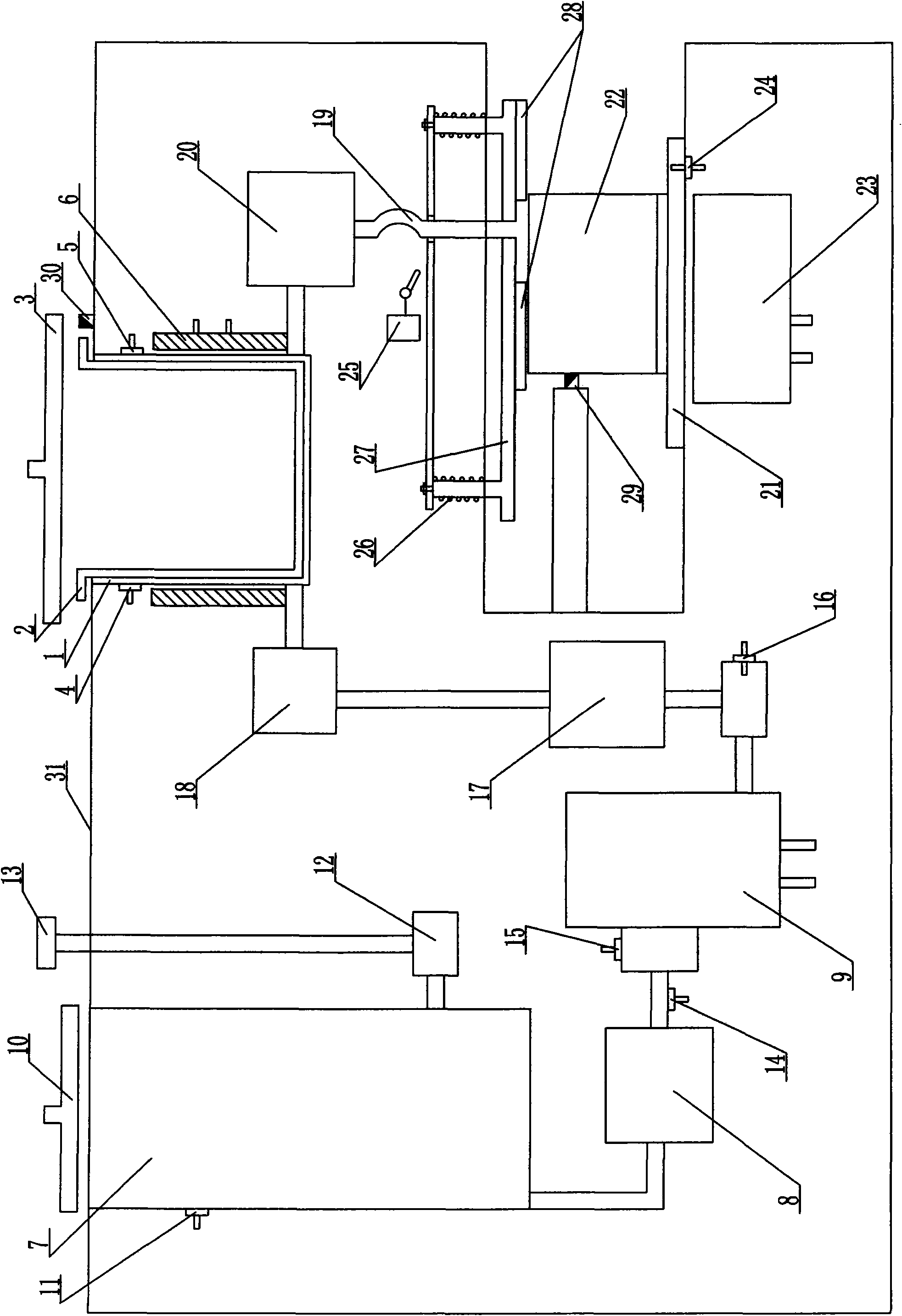

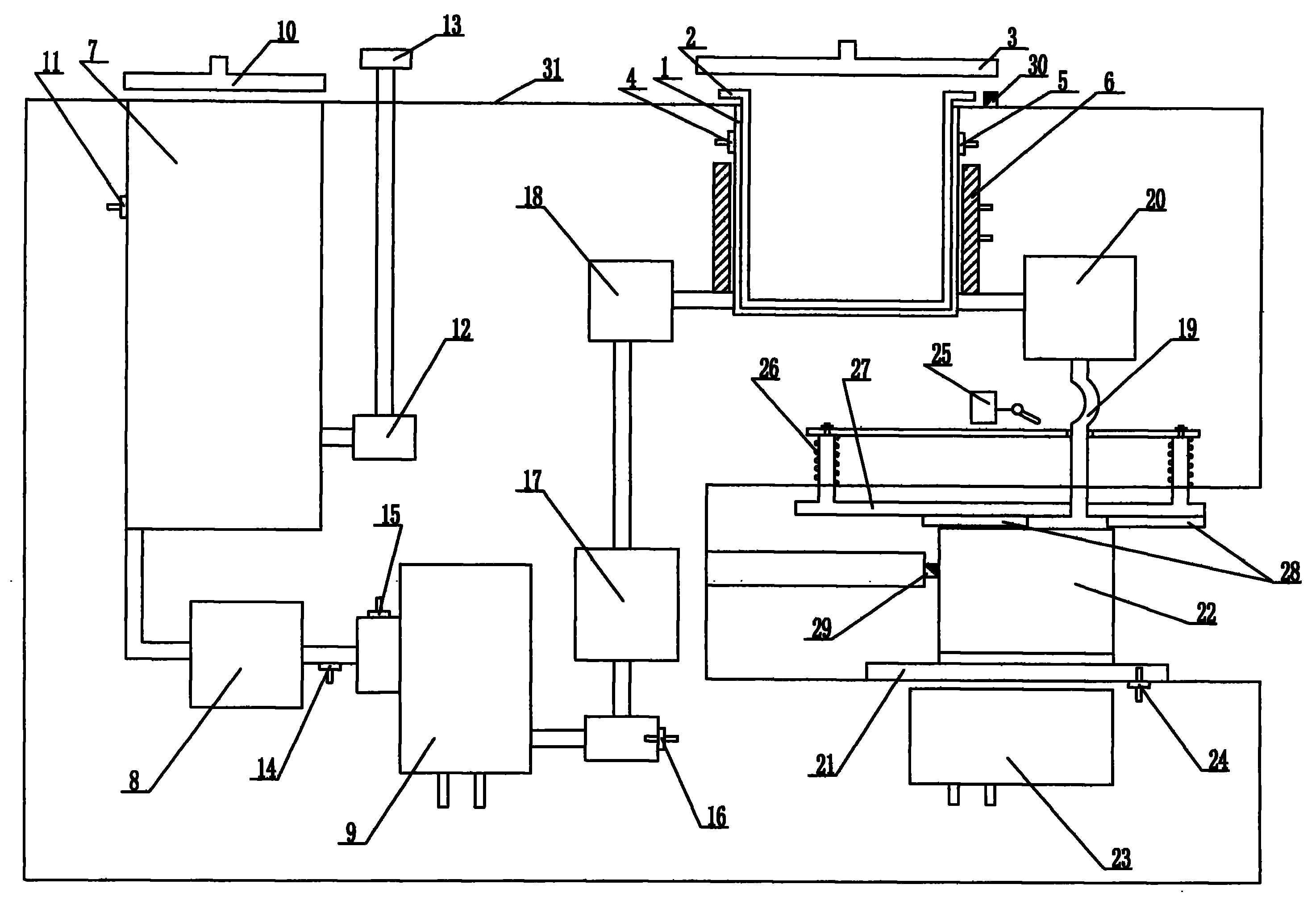

[0016] Attached below figure 1 , 2 The present invention is further described.

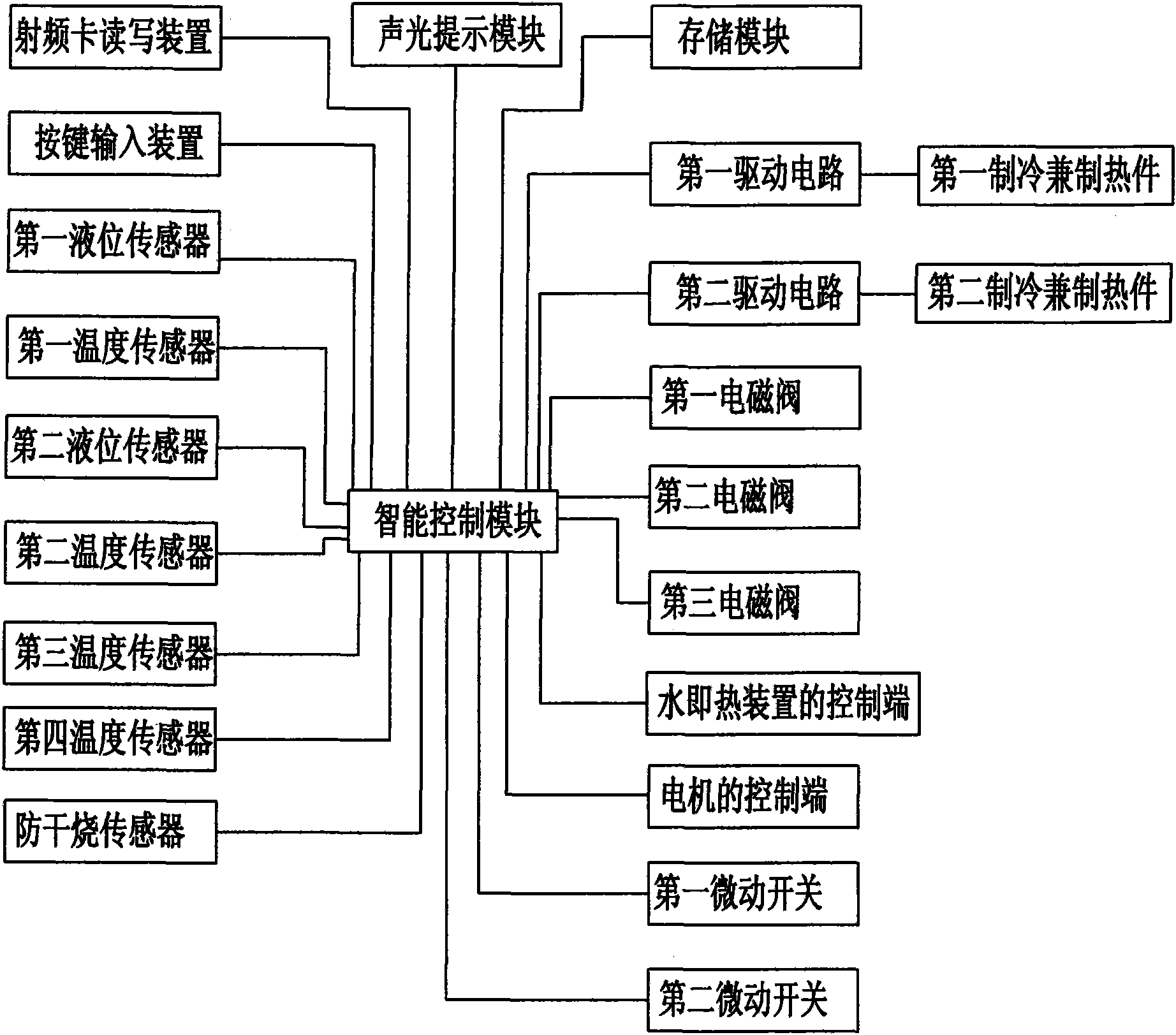

[0017] The tea making machine of the present invention includes a water supply unit, a tea making unit, a tea outlet unit and a control unit, the tea making unit includes a water container 1, a water permeable container 2 and a cover 3, and the water permeable container 2 is provided with a scale indicating the water depth , the permeable container 2 is detachably installed in the water container 1, the control unit includes an intelligent control module, an input module, a storage module and an acousto-optic prompt module, and the input module, the storage module and the acousto-optic prompt module are respectively connected with the intelligent The control module is electrically connected, and it also includes a first temperature control device and a first liquid level sensor 4 installed in the water container 1, and the first temperature control device and the first liquid level sensor 4 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com