Demoulding mechanism of spiral undercut

A technology of demoulding mechanism and spiral, which is applied in the field of spiral barb demoulding mechanism, can solve the problems of troublesome mold assembly and complex structure, and achieve the effects of easy assembly, simple structure of demoulding mechanism and cost saving of mold assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

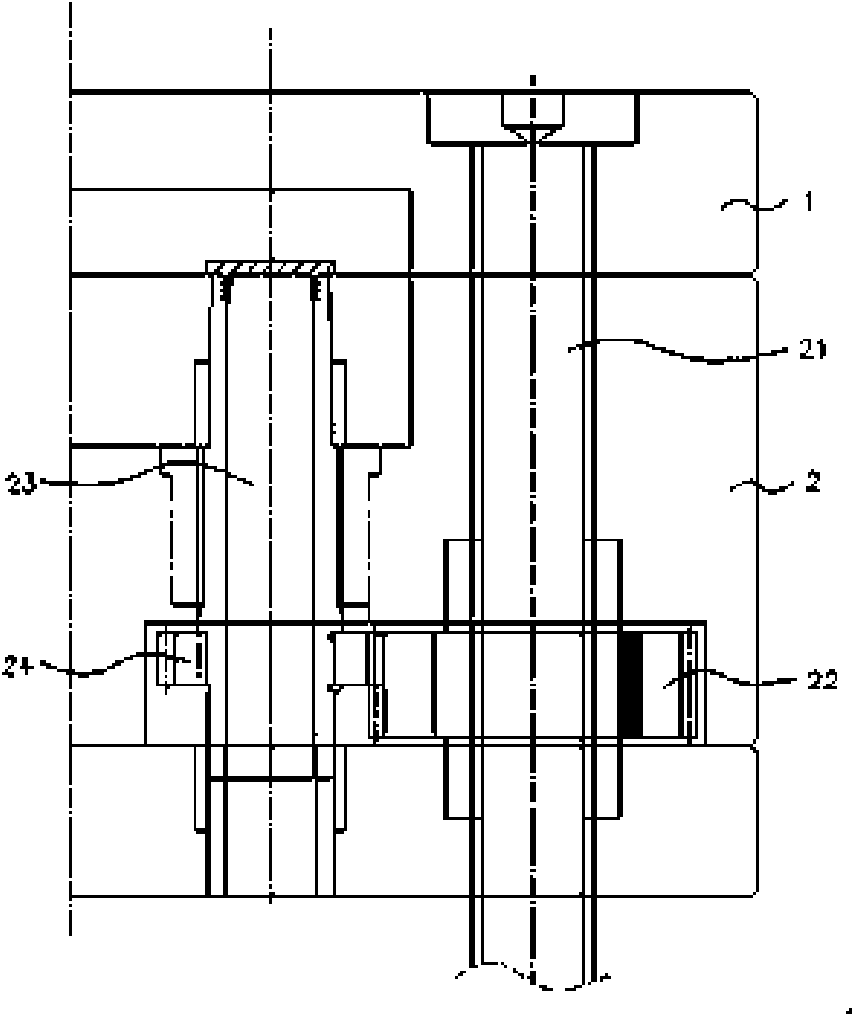

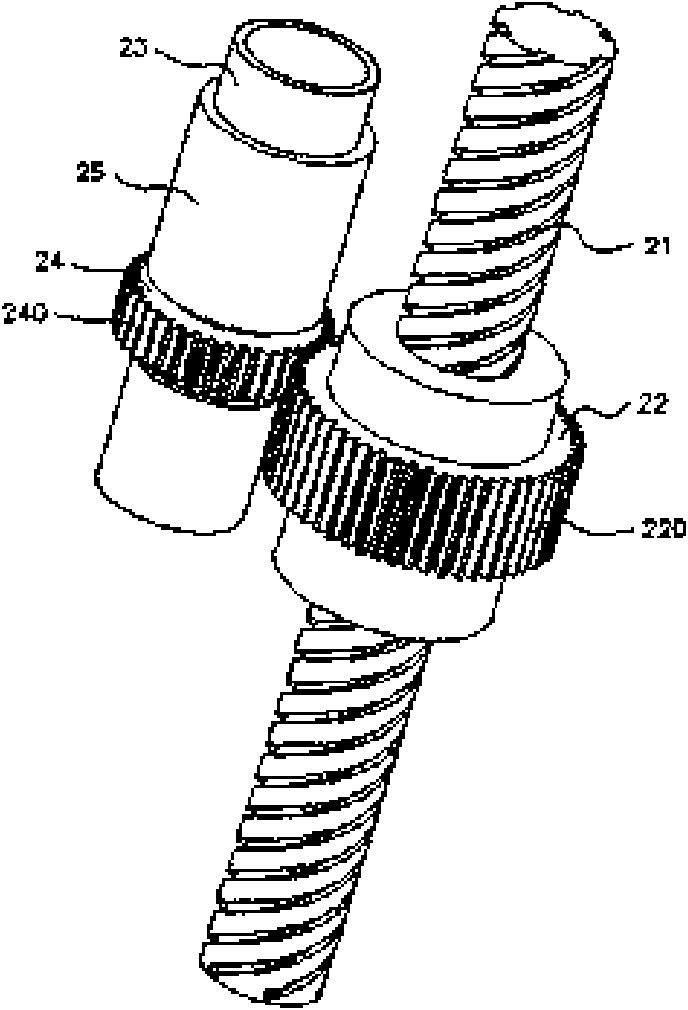

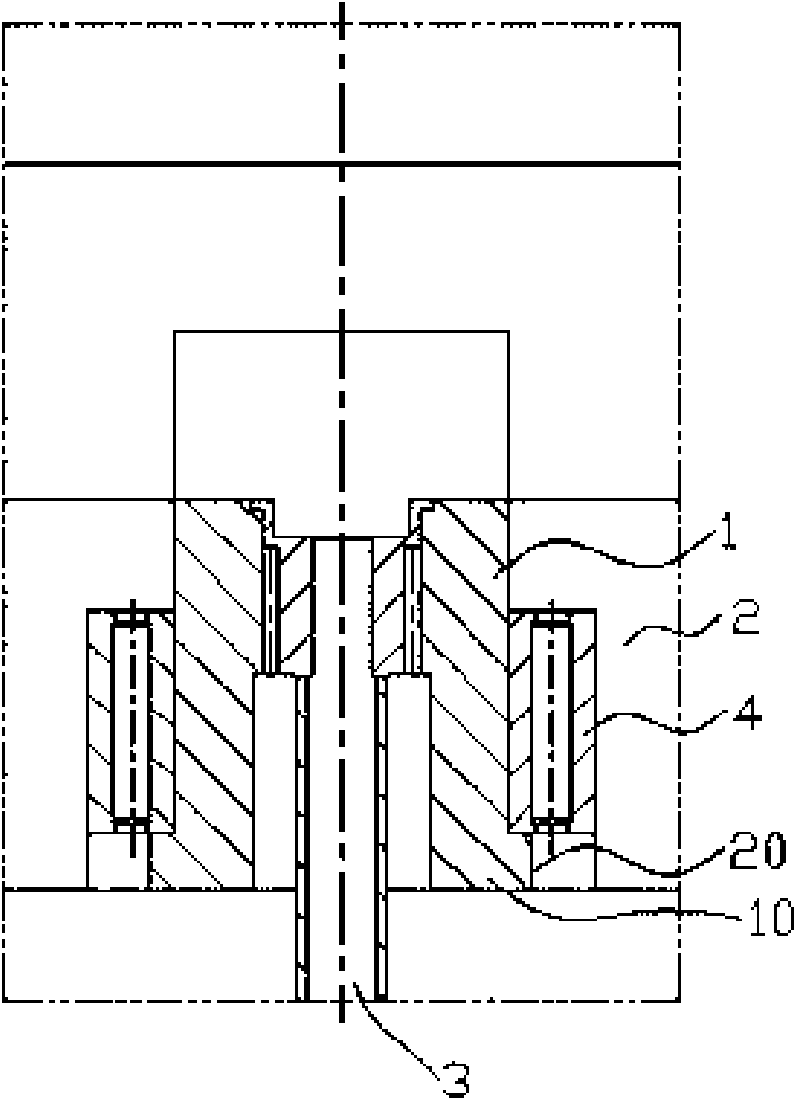

[0014] see image 3 The planar dissection structure schematic diagram of the demoulding mechanism of spiral barb of the present invention and Figure 4 As shown in the partial three-dimensional structure schematic diagram of the demoulding mechanism of the spiral barb of the present invention, the demoulding mechanism of the spiral barb is suitable for the production of spiral barb product molds with a helix angle greater than 45 degrees, which includes:

[0015] A rotary screw insert 1, the bottom of which extends a circle of convex portion 10 along its axial direction, and a groove 20 corresponding to the above-mentioned convex portion 10 is provided in the male template 2 of the above-mentioned mold, through the above-mentioned convex portion 10 and The cooperation of the above-mentioned groove 20 clamps the above-mentioned rotary screw inserter 1 in the male template 2 of the above-mentioned mould, and the rotary screw inserter 1 performs a horizontal rotation movement in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com