Servo energy-saving device of injection molding machine and energy saving method

An energy-saving device and injection molding machine technology, applied in the field of injection molding machine servo energy-saving devices, can solve energy waste and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] With reference to the drawings, the present invention will be further described below.

[0014] Main components of equipment:

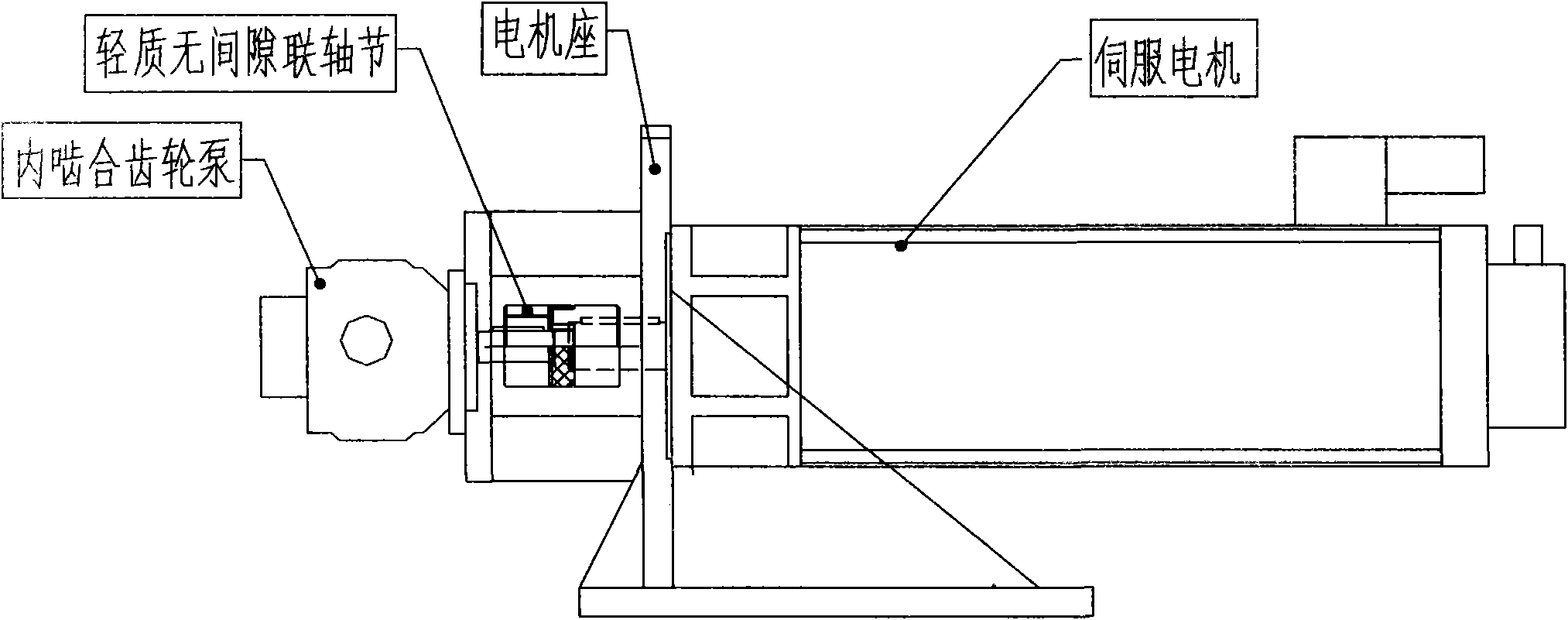

[0015] Such as figure 1 :Servo motor, motor base, light-weight non-backlash coupling, internal gear pump, the servo motor is fixed on the motor base by screws, the gear pump is fixed on the motor base by screws, the servo motor and gear The pump is connected by a lightweight, gapless coupling.

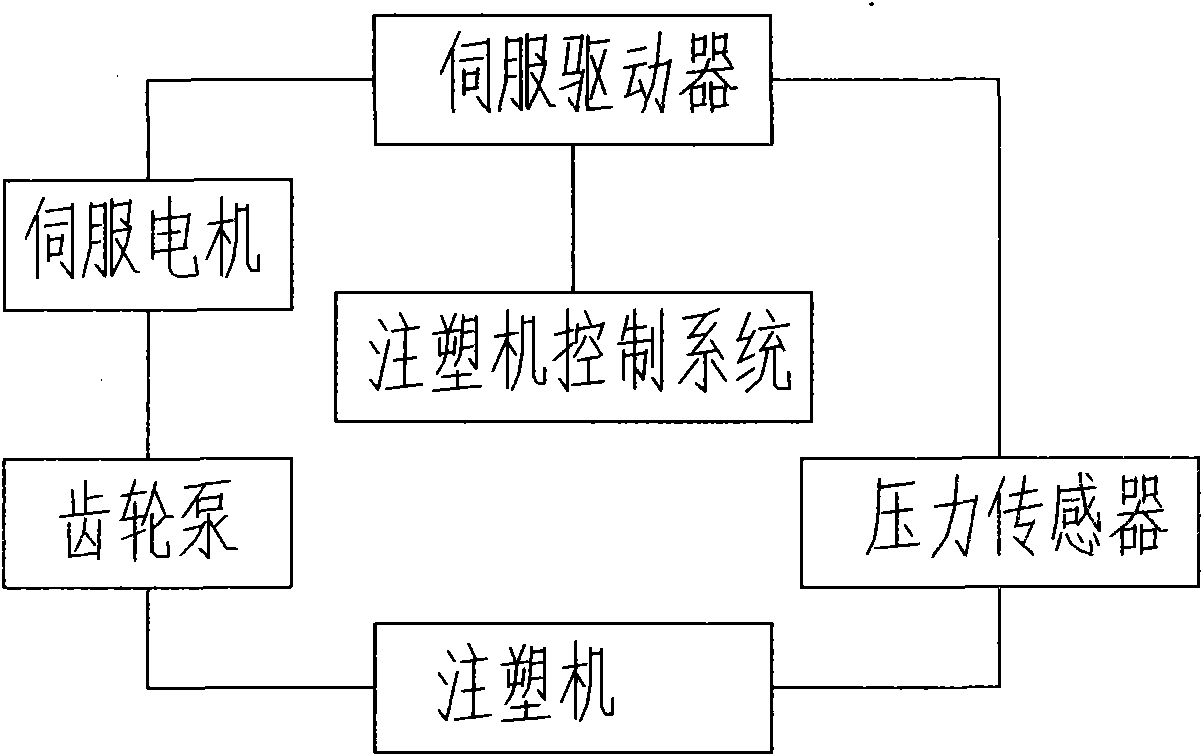

[0016] Such as figure 2 :Injection molding machine, injection molding machine control system, servo motor, pressure sensor, gear pump, servo driver. The injection molding machine is the target device of this patent. The injection molding machine control system is installed on the injection molding machine and controls various actions of the injection molding machine. , The servo motor and gear pump press figure 1 After the connection is shown, it is installed on the injection molding machine, the pressure sensor is installed on the injection molding machine,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com