Method for recovering, smelting and reusing base material in jet mill procedure for sintered NdFeB production

A jet mill and NdFeB technology, applied in the direction of improving process efficiency, can solve the problem that the bottom material cannot be processed and reused, and achieve the effect of shortening the recycling cycle, simple process, and the same product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

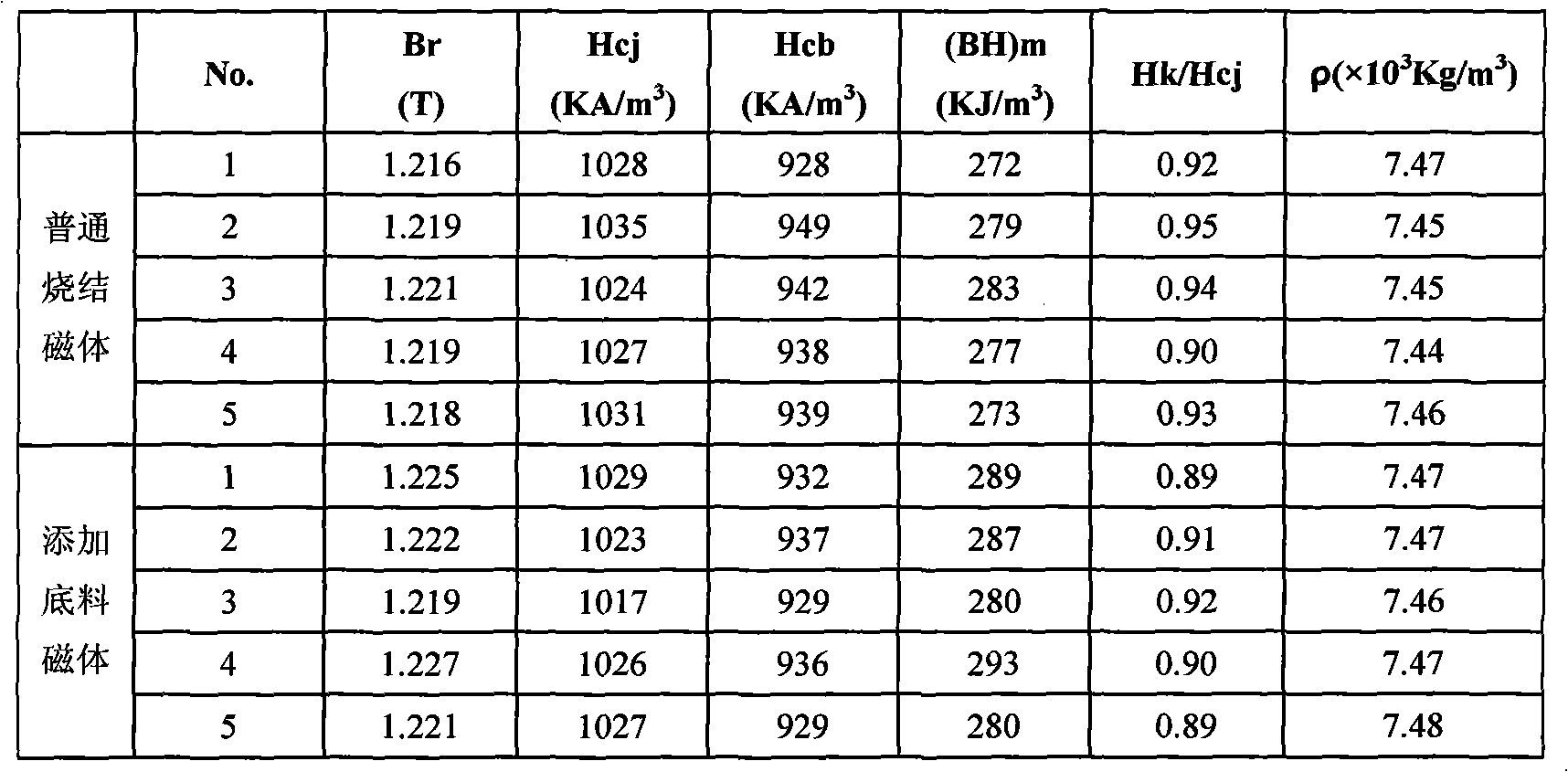

Embodiment 1

[0018] Embodiment 1. A method for recycling, smelting and reusing bottom material in jet milling process by sintering NdFeB, comprising the following steps:

[0019] (1) The collection and airtight storage of jet mill bottom material:

[0020] Centrally store the hard-to-break bottom material produced by the jet mill process, and store it in a sealed nitrogen-filled environment to prevent the increase in oxygen content during storage. In order to prevent the oxidation of the powder, the sealed tank is filled with nitrogen for protection; generally, when the oxygen content of the powder is ≤5000ppm, this method is suitable for addition and utilization (the base material can be stored within 10 days under the condition of filling nitrogen).

[0021] (2). Add the collected air-jet grinding bottom material to the normal material at a ratio of 10% during the ingot batching and smelting together. The adding method: select a roll-shaped industrial 0.1mm thick plain aluminum foil and ...

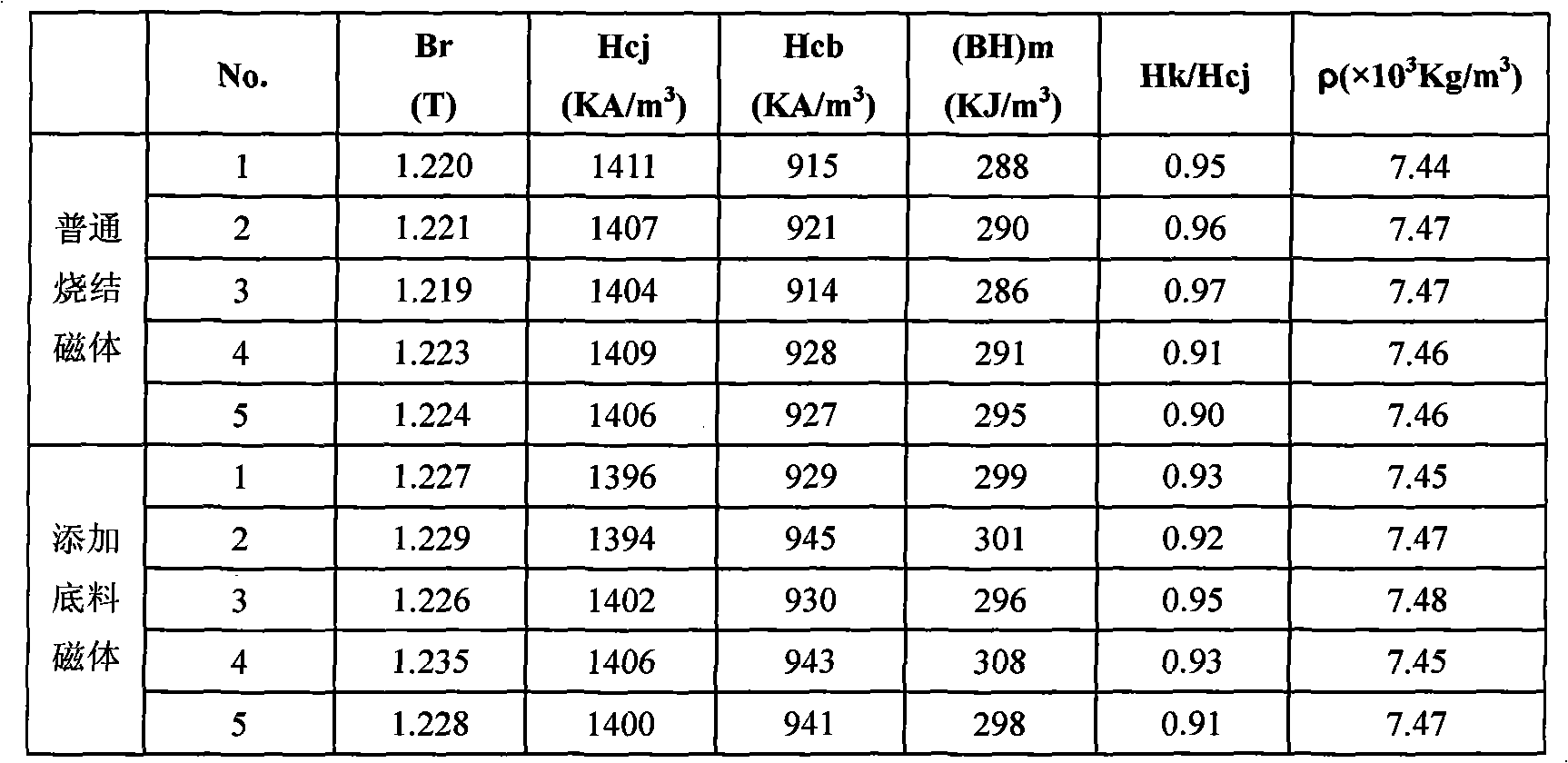

Embodiment 2

[0026] Embodiment 2, a method for recovering, smelting and reusing the base material in the jet mill process of sintering NdFeB production, comprising the following steps: collecting and sealing the jet mill base material:

[0027] Add 0.15% (weight ratio) of Pr-Nd alloy ingredients according to the designed 35H grade formula, select the plain aluminum foil with a thickness of 0.2mm in the roll industry, cut it into aluminum foil paper with a size of 300×300mm, and wrap the base material with 5% of the raw material weight Covering, the insufficient part of the metal Al is made up with the cut aluminum plate; after it is prepared, it is smelted together, and the subsequent process is the same as the normal sintered NdFeB production process: powder making, molding, sintering, tempering, and testing of magnetic properties. From the results in Table 2, it can be seen that the performance indicators of the magnets added with the primer are basically the same as those of the magnets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com