Packaging method of LED (light-emitting diode) flexible lamp strip

An encapsulation method and a technology for flexible light bars, which are applied to lighting devices, lighting device parts, light sources, etc., can solve the problems of high production cost, complex process, low production efficiency, etc., and achieve low equipment maintenance costs and simple production process. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

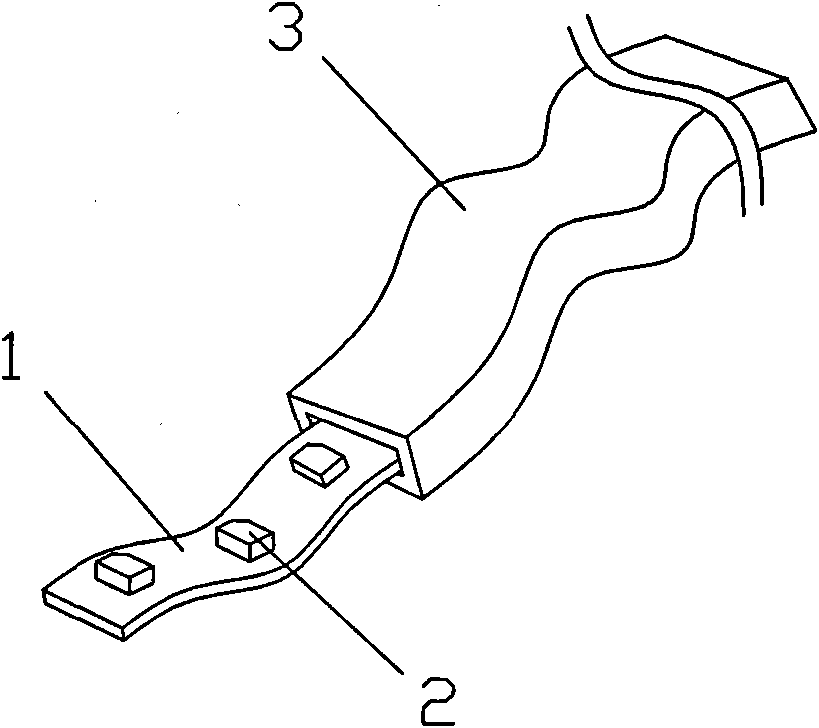

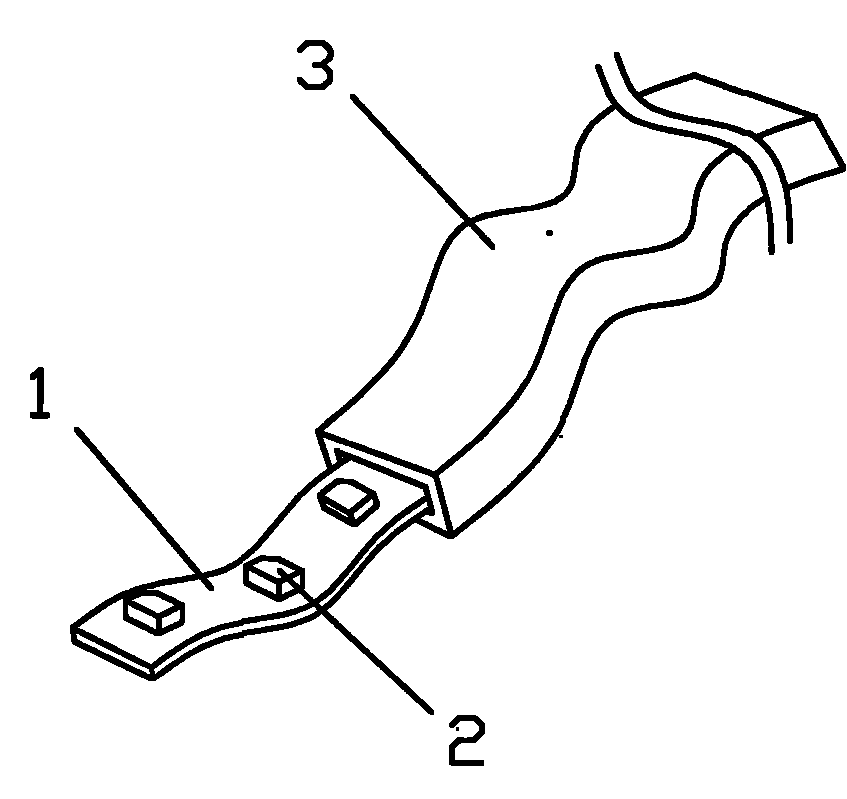

[0019] refer to figure 1 , the present invention a kind of LED flexible light bar packaging method, comprises the following steps:

[0020] 1) Provide a flexible circuit board 1;

[0021] 2) Provide several in-line or SMD LED light sources 2;

[0022] 3) Welding the above-mentioned LED light source 2 on the above-mentioned flexible circuit board 1 by means of reflow soldering or wave soldering;

[0023] 4) Provide a strip-shaped flexible shell 3;

[0024] 5) importing the above-mentioned flexible circuit board 1 welded with the LED light source into the above-mentioned flexible housing 3;

[0025] 6) Inject glue into the flexible shell 3 and let it dry and solidify.

[0026] Above-mentioned technical scheme also can have following improvement scheme: described step 5) comprises the following steps:

[0027] ①Through the steel wire through the flexible shell, the two ends of the steel wire are exposed outside the flexible shell;

[0028] ②Connect the end of the flexible c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com