Backlight module and liquid crystal display device

A technology of backlight module and fixing device, which is applied to lighting devices, fixed lighting devices, lighting auxiliary devices, etc., achieves the effects of convenient and quick assembly, increased light use efficiency, and increased heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

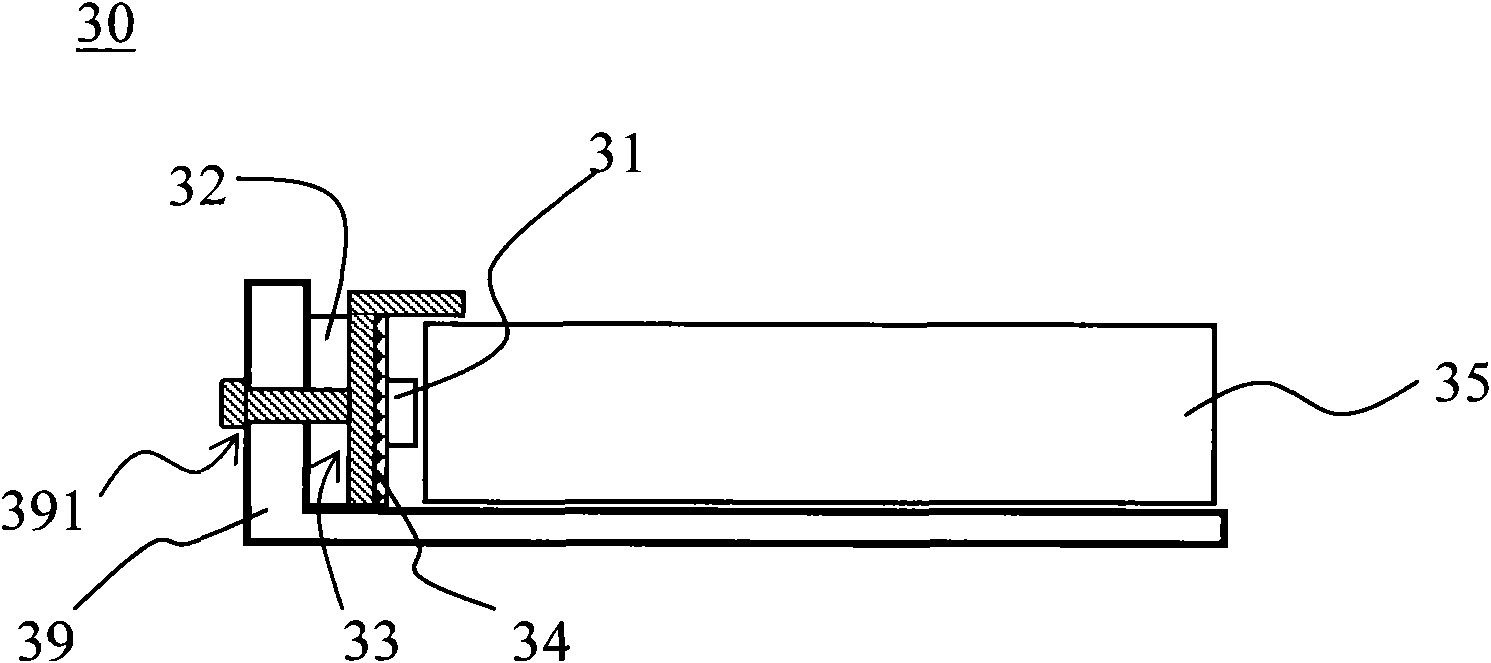

[0026] See image 3 , image 3 It is a schematic cross-sectional view of an edge-lit LED backlight module 30 according to an embodiment of the present invention. The backlight module 30 includes a back frame 39 , a light guide plate 35 , a fixing device 33 and an LED light bar, wherein the LED light bar includes an LED light source 31 and a circuit board 32 . Please refer to Figure 5 , Figure 5 It is a structural schematic diagram of an LED light bar according to an embodiment of the present invention. The light guide plate 35 and the LED light strips are disposed in the back frame 39 . The LED light sources 31 are arranged at intervals on the circuit board 32 , and the light-emitting surfaces of the LED light sources 31 face the light guide plate 35 . The cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com