Drop impact testing machine for large dangerous cargo transporting package containers

A technology for dangerous goods and packaging containers, which is applied in the field of impact drop testing machines for large-scale dangerous goods transportation packaging containers, can solve the problems of no equipment, no drop test equipment products, unsafe and other problems, achieve low mechanical noise, eliminate safety hazards, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

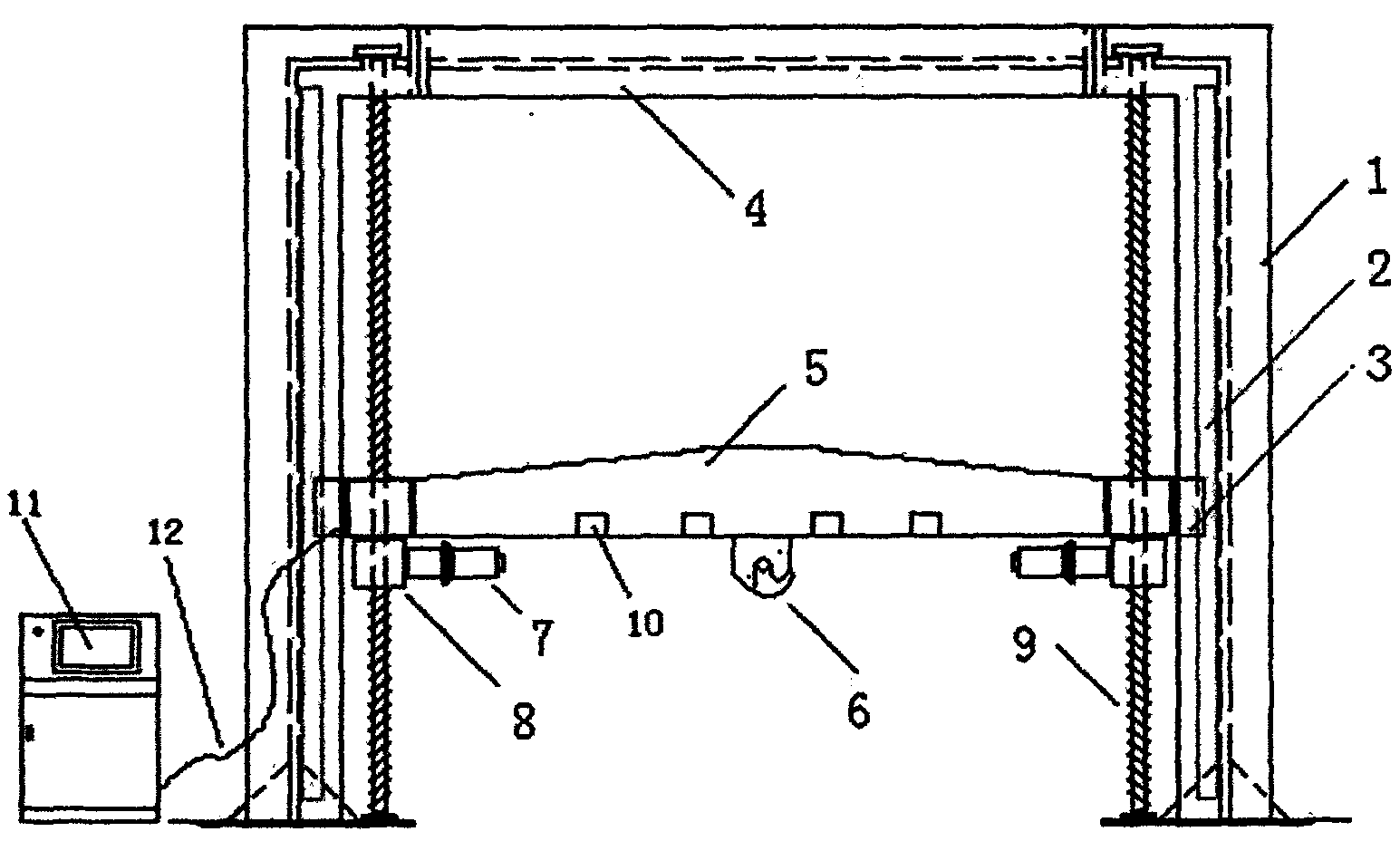

[0013] Such as figure 1 , 2 , 3, the support column 1 and the fixed crossbeam 4 are all made of I-beams to ensure the overall safety and stability of the equipment. The support column 1 and the fixed beam 4 are connected with bolts, and the support column 1 is welded with the fixed plate 13, which is convenient for transportation and installation after the equipment is processed. Considering that the large-weight test piece needs to have a certain width and height requirements, the net span of the special testing machine is ≥ 3 meters, and the distance between the fixed beam 4 and the anvil surface is ≥ 3.8 meters.

[0014] The sliding guide device is composed of a guide rail 2 and a slider 3, the guide rail 2 is fixed on the inner side of the I-shaped steel support column 1, the slider 3 is connected with the movable beam 5, and the two screw screws 9 are respectively installed on the inner side of the two support column 1 And parallel to the two supporting columns 1, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com