Dye-sensitized solar cell module and preparation method thereof

A technology of solar cells and dye sensitization, which is applied in the field of solar cells, can solve problems such as mutual pollution, energy loss, and complex processes, and achieve the effects of reducing area waste, increasing yield, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

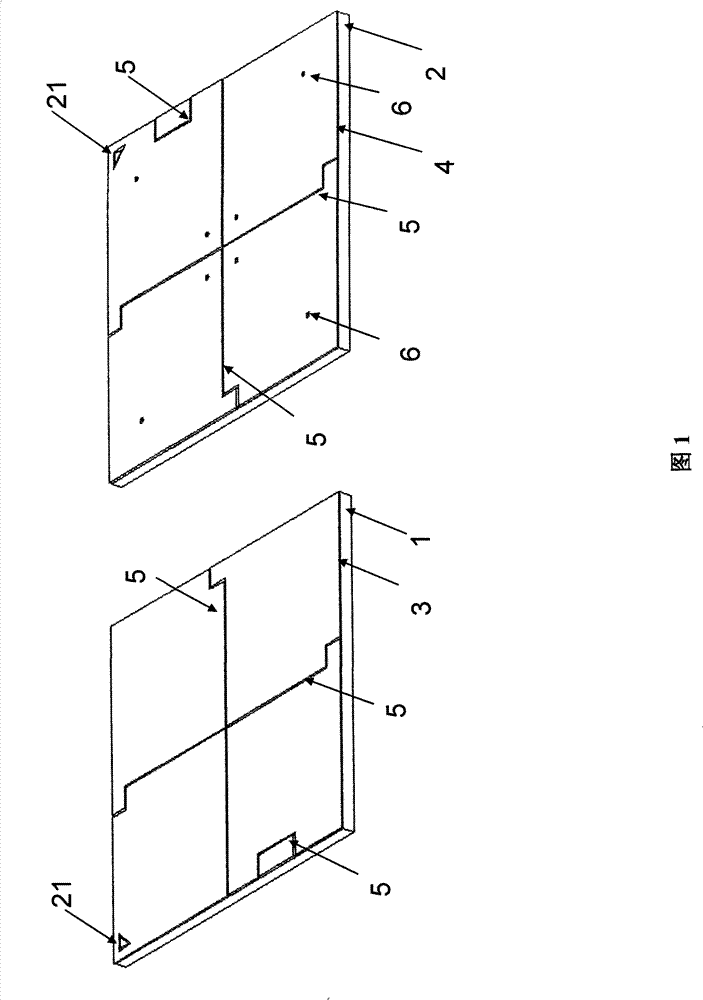

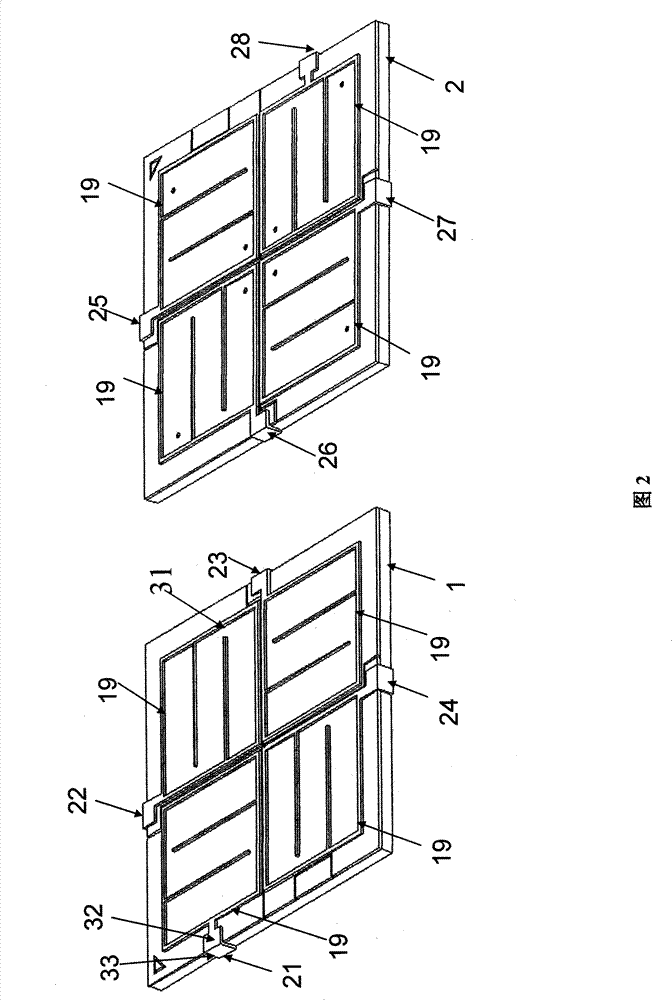

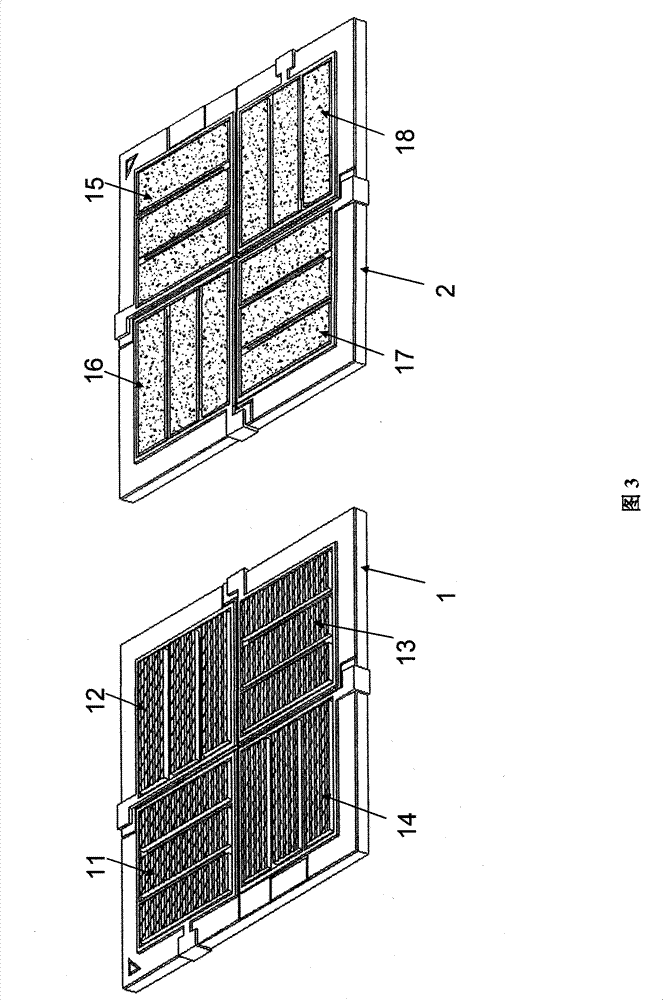

[0037] The dye-sensitized solar cell module of this embodiment is composed of 12 basic battery units, of which 3 basic battery units form a parallel component, and 4 parallel components are sequentially connected in series to form the battery module.

[0038] refer to Figure 7 , The basic battery unit of this embodiment includes from bottom to top: a lower substrate 2 , a lower substrate conductive layer 4 , a counter electrode 8 , an electrolyte 9 , a photoanode 7 , an upper substrate conductive layer 3 and an upper substrate 1 . Both the conductive layer 3 of the upper substrate and the upper substrate 1 are made of transparent materials. Conductive mesh 19 (refer to figure 2 ). On the one hand, the conductive grid 19 increases the conductivity of the conductive layer, and on the other hand, it separates each basic battery unit. The conductive grid 19 is covered with an encapsulation isolation layer 10 for sealing and isolating the electrolyte 9 . In this implementatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com