Energy-saving concentration process for extracting active ingredients of plants and concentration device thereof

A technology of active ingredients and extraction devices, which is applied in the field of biological separation and extraction, can solve problems such as destruction, denaturation of active ingredients, reduction of extract quality and efficacy, and achieve the effects of good quality, reduced oxidative denaturation and loss, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

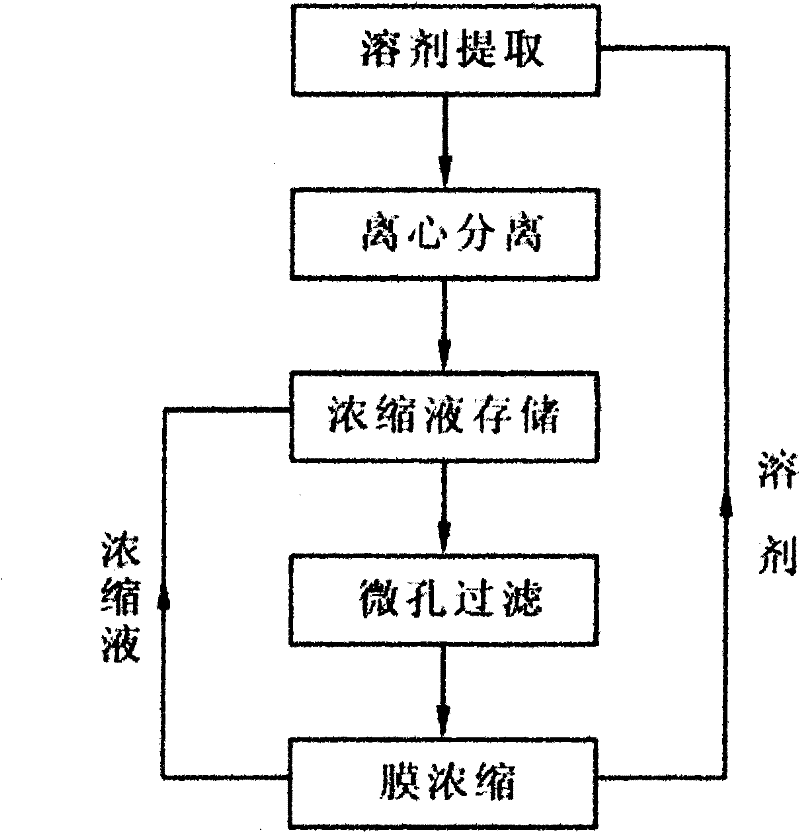

Method used

Image

Examples

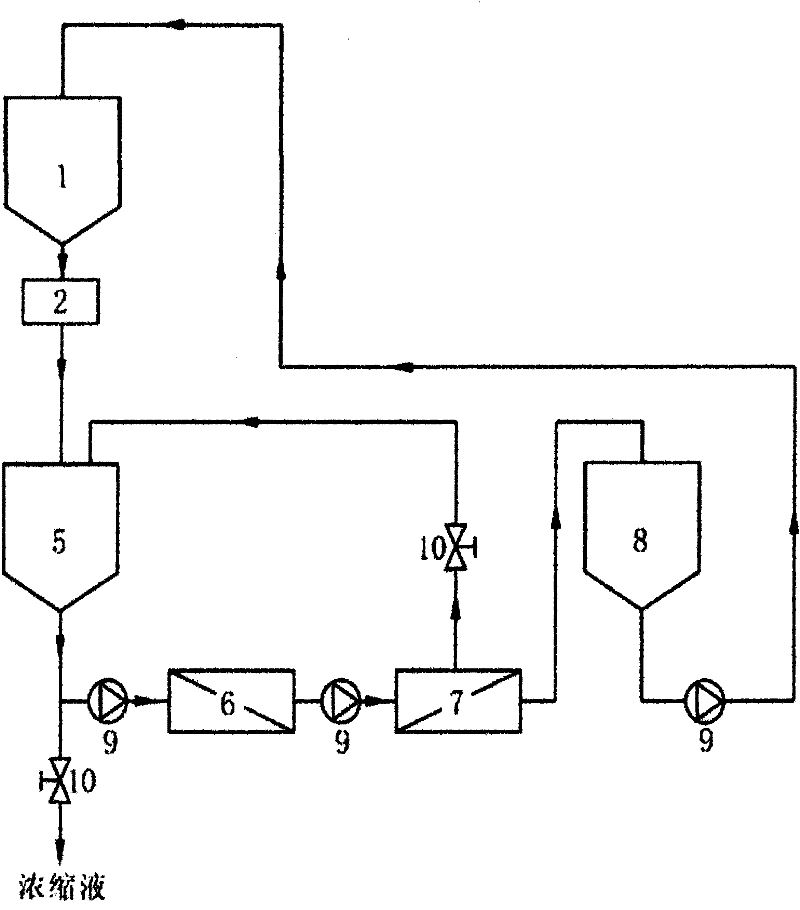

Embodiment 1

[0039] This example is a pilot test for the extraction and concentration of Radix isatidis. Take 200 kg of crude extract from the extraction device 1, and centrifuge it in a sedimentation centrifuge to obtain a clarified liquid. The clarified liquid is cooled to 35°C and enters the concentration circulation tank 5. From the clarified The liquid is pumped into the microfiltration device (the pore size is 2 μm), and the permeate enters the membrane concentration device, and is concentrated in circulation for 20 minutes to obtain the concentrate and water solvent (permeate). The specific analysis results are shown in the table below.

[0040] Concentration effect analysis:

[0041] project Raw material liquid Concentrate Permeate Concentration rate Test results 200kg 39kg 161 80.5%

[0042] Permeate analysis results:

[0043] Analysis Project Chroma Turbidity naked eye TDS Conductivity hardness COD Test results ...

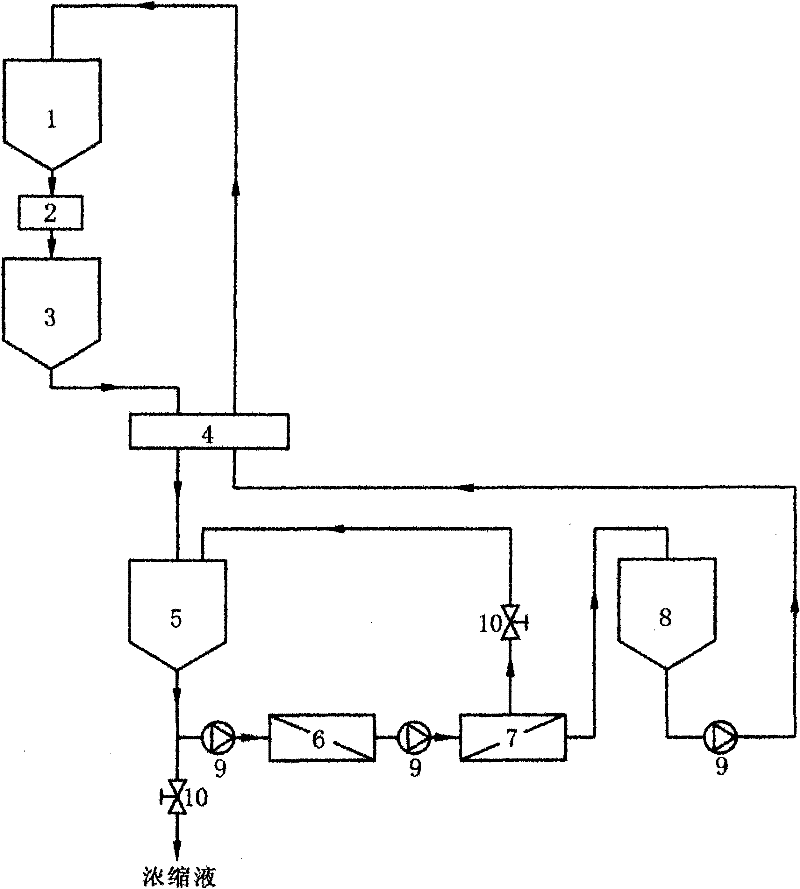

Embodiment 2

[0047] This embodiment is a test of performing membrane centrifugation and concentration on the extract solution eluted from the ethanol chromatography column of Panax notoginseng. Take 20L of the ethanol extract of Panax notoginseng and send it into the device of the present invention to carry out membrane centrifugal separation and concentration according to the process of the present invention. After circulating for 25 minutes, concentrate and ethanol solvent (permeate) were obtained, and the specific analysis results were as follows.

[0048]

[0049] Features of the present invention:

[0050] 1. Simple structure, simple process flow, short working time and high efficiency;

[0051] 2. Concentrate without heating, energy saving and environmental protection, more than 90% energy saving compared with the existing technology;

[0052] 3. Concentration without heating reduces the oxidative denaturation and loss of active ingredients caused by evaporation and concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com