Method for preparing low-fishy and low-bitter functional food by using acid-soluble protein of tilapia meat

A tilapia meat, acid-soluble technology, applied in the field of fish protein acquisition and utilization, can solve the problems of high product loss, loss, and high process requirements, reduce fishy smell and bitterness, improve inhibitory activity, and be easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

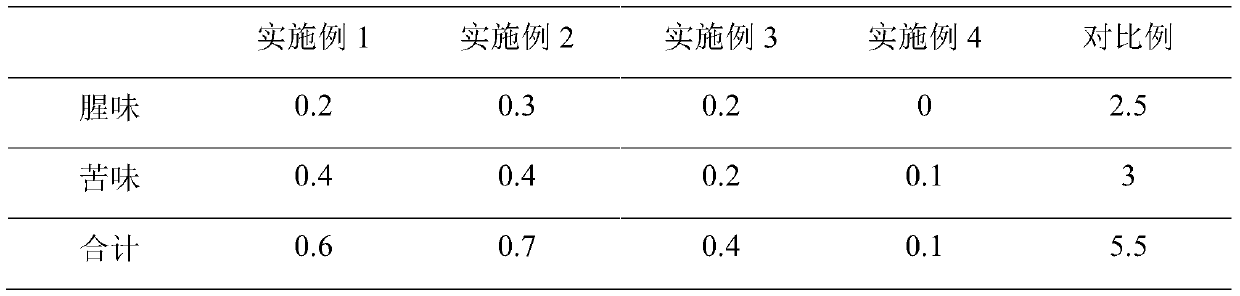

Embodiment 1

[0029] A method for preparing a low-fishy and low-bitter vascular polypeptide by using the acid-soluble protein of tilapia meat. The acid-soluble protein of tilapia meat, tea polyphenols, and water are mixed according to the mass ratio of 320:1:1000, and 30000U / g tilapia meat Add papain to the proportion of acid-soluble protein, enzymatically hydrolyze at pH 6 and temperature 35°C for 4 hours, remove insoluble matter to obtain enzymolyzed solution, heat to boiling, keep warm for 10 minutes, and then quickly cool to room temperature, using molecular cut-off of 10,000 Dalton ultrafiltration device ultrafiltration to obtain the filtrate, and dry it.

Embodiment 2

[0031] A method for preparing a low-fishy and low-bitter functional food using the acid-soluble protein of tilapia meat. The acid-soluble protein of tilapia meat, tea polyphenols, and water are mixed according to the mass ratio of 380:10:1000, and the mixture is prepared according to the mass ratio of 60000U / g tilapia meat. Add papain to the proportion of acid-soluble protein, enzymolyze at pH 7 and temperature 55°C for 8 hours, remove insoluble matter to obtain enzymolyzate, heat to boiling, keep warm for 10 minutes, and then quickly cool to room temperature, using molecular cut-off of 10,000 Dalton ultrafiltration device ultrafiltration to obtain the filtrate, and dry it.

Embodiment 3

[0033] A method for preparing a low-fishy and low-bitter functional food by using the acid-soluble protein of tilapia meat. The acid-soluble protein of tilapia meat, tea polyphenols, and water are mixed according to the mass ratio of 350:5:1000, and the amount is 50000U / g of tilapia meat. Add papain to the proportion of acid-soluble protein, enzymatically hydrolyze at pH 6.5 and temperature 45°C for 6 hours, remove insoluble matter to obtain enzymolyzed solution, heat to boiling, keep warm for 10 minutes, and then quickly cool to room temperature, using molecular cut-off of 10,000 Dalton ultrafiltration device ultrafiltration to obtain the filtrate, and dry it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com