Nano coating of negative electrode materials and preparation method of secondary aluminium cell using negative electrode materials

A technology of secondary aluminum battery and negative electrode active material, applied in secondary battery, electrode manufacturing, battery electrode and other directions, can solve the problems of oxide film damage, low theoretical capacity, complex synthesis process, etc., to achieve corrosion-resistant storage and transportation, Easy to store and transport, high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

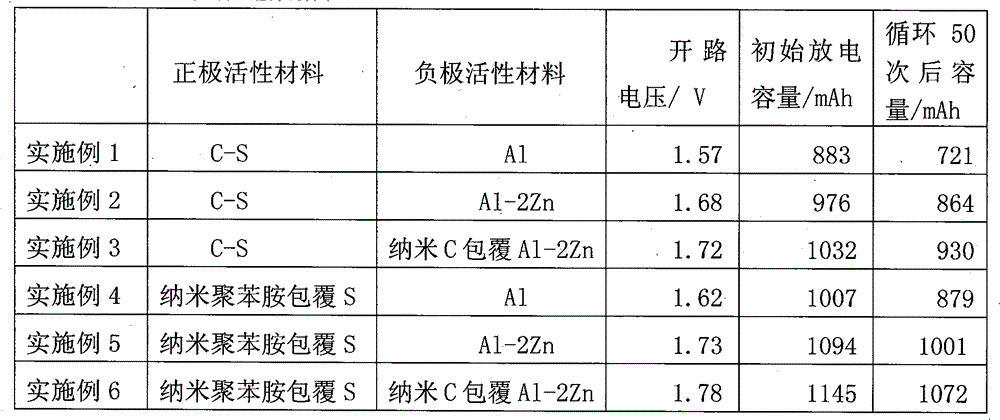

Embodiment 1

[0041] In the positive electrode active material prepared by the carbon-sulfur composite material with a mass ratio of C:S of 1:3, a conductive agent: super conductive carbon black (SUPER-P) and binder PVDF were added at a ratio of 7:2:1. The positive electrode active material slurry is coated on a 0.6mm thick nickel foam substrate, dried and rolled to 0.3mm and cut into 40mm wide × 150mm long pole pieces, and a 0.16mm thick glass fiber non-woven diaphragm and an aluminum sheet are used as The negative electrode made of the negative electrode active material is wound into a battery cell and put into a nickel-plated steel case, then an organic electrolyte is added, and the seal is made into an AA-shaped cylindrical secondary aluminum battery. During the battery charge and discharge cycle test, charge at 0.5C, discharge at 1C, and discharge cut-off voltage is 1.2V. The charge and discharge data are listed in Table 1.

Embodiment 2

[0043] The preparation method of the positive electrode is the same as in Example 1, and the active material of the negative electrode is Al-2Zn alloy coated on the nickel foam current collector, and the battery is assembled according to the same method as in Example 1. During the battery charge and discharge cycle test, charge at 0.5C, discharge at 1C, and discharge cut-off voltage is 1.2V. The charge and discharge data are listed in Table 1.

Embodiment 3

[0045] The preparation method of the positive electrode is the same as in Example 1, and the negative electrode active material is nano-C surface-coated Al-2Zn alloy, which is coated on the foamed nickel current collector, and the battery is assembled in the same manner as in Example 1. During the battery charge and discharge cycle test, charge at 0.5C, discharge at 1C, and discharge cut-off voltage is 1.2V. The charge and discharge data are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com