Precise rolling work roll fracture handling method

A treatment method and technology of work rolls, which are applied in the direction of roll safety equipment, metal rolling, manufacturing tools, etc., can solve problems affecting the smooth progress of production, damage to water cutting boards and guides, complex rolling mill conditions, etc., to improve accidents Treatment efficiency and mill operating rate, elimination of secondary damage and scratching problems, easy to master and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, the present invention will be further described in conjunction with the accompanying drawings.

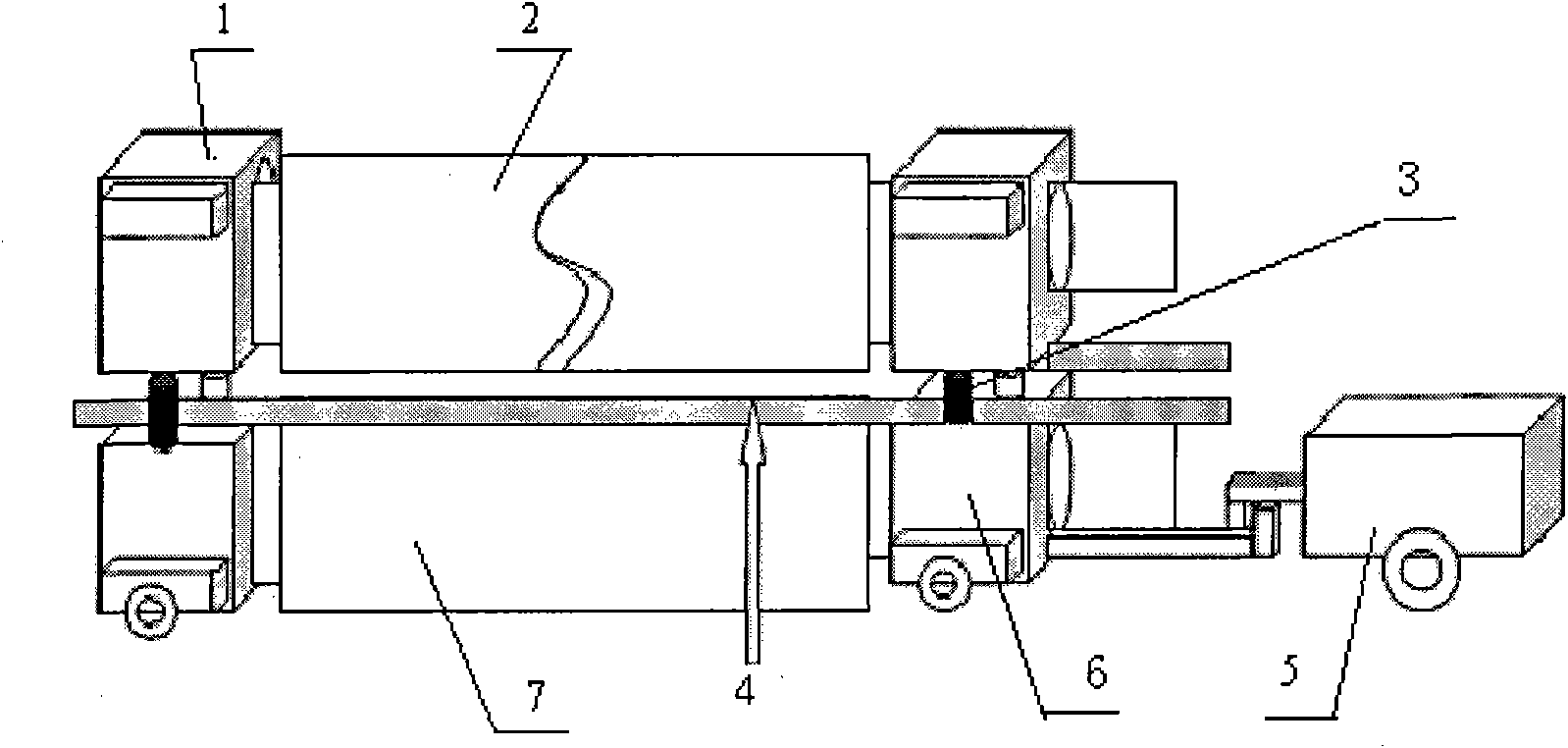

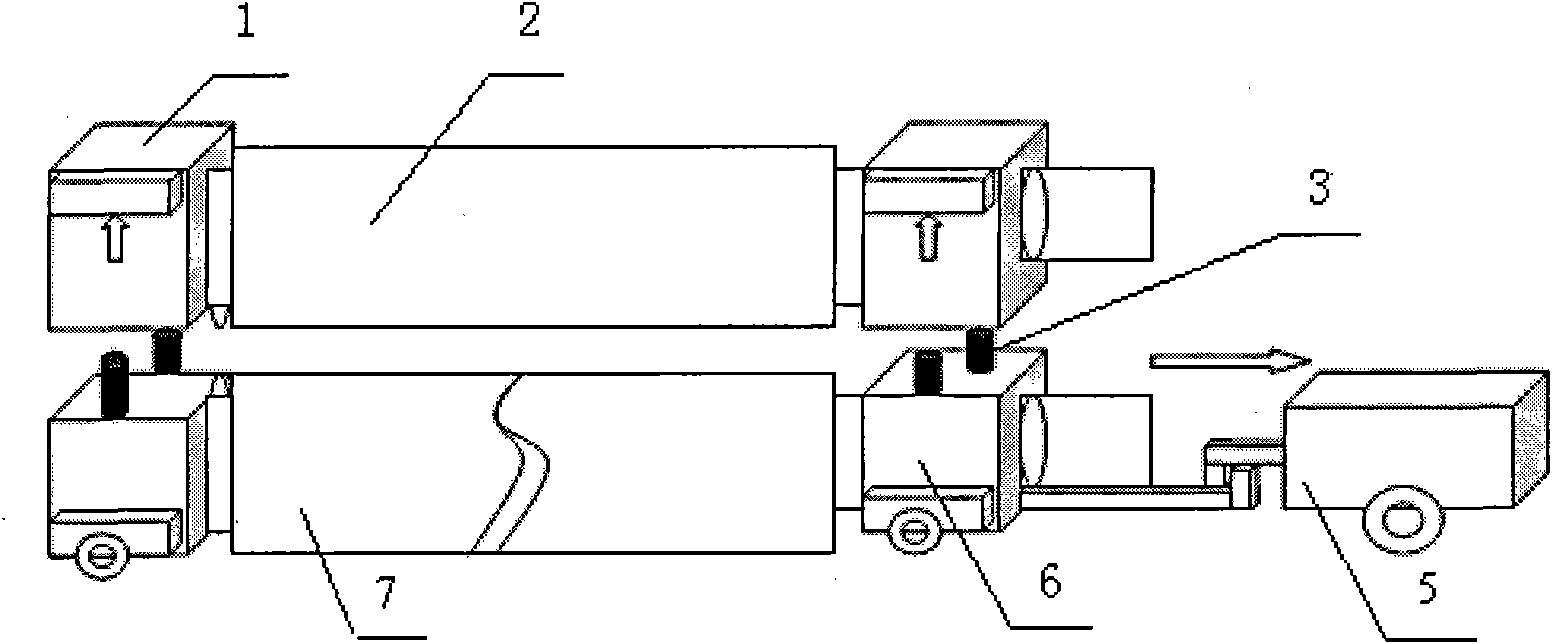

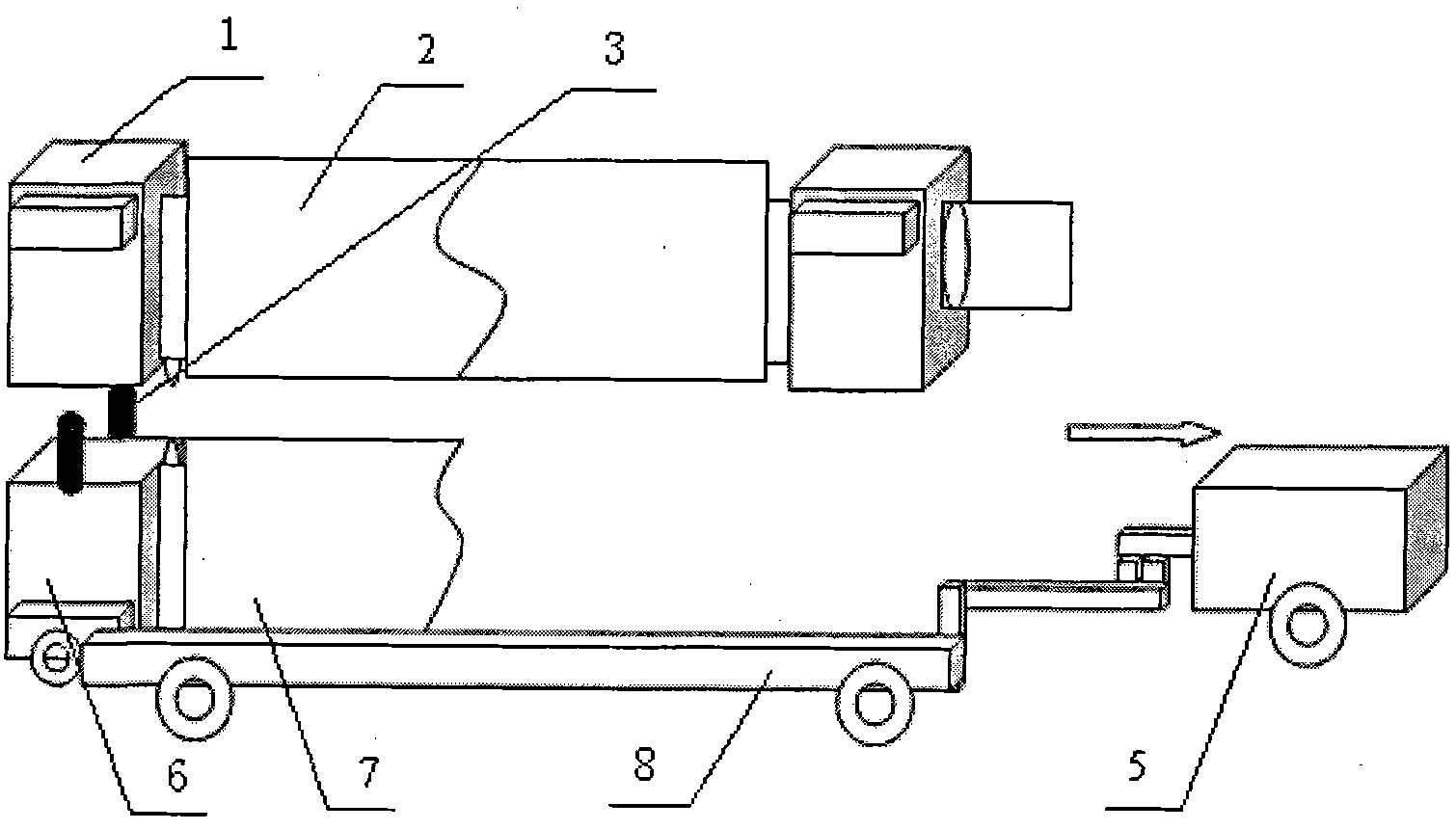

[0023] Finishing work rolls include upper work roll 2 and lower work roll 7. Therefore, there are three types of work roll breakage accidents: upper work roll breakage, lower work roll breakage, and upper and lower work roll breakage. The treatment methods must also be based on For the type of broken roll, take corresponding treatment methods respectively. The specific steps and methods are:

[0024] Treatment method for upper work roll broken roll:

[0025] like figure 1 As shown, the upper work roll 2 is broken, while the lower work roll 7 is intact. In this case, it is first necessary to confirm the situation at the broken roll of the upper work roll 2. If the broken roll remains at the same axial position and the fracture does not deviate toward the exit or entrance of the rolling mill, the treatment method is: first, turn the rolling mill automatically Contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com