Full-automatic nut wielding machine

A welding machine, fully automatic technology, used in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve problems such as low production efficiency and easy to cause industrial accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

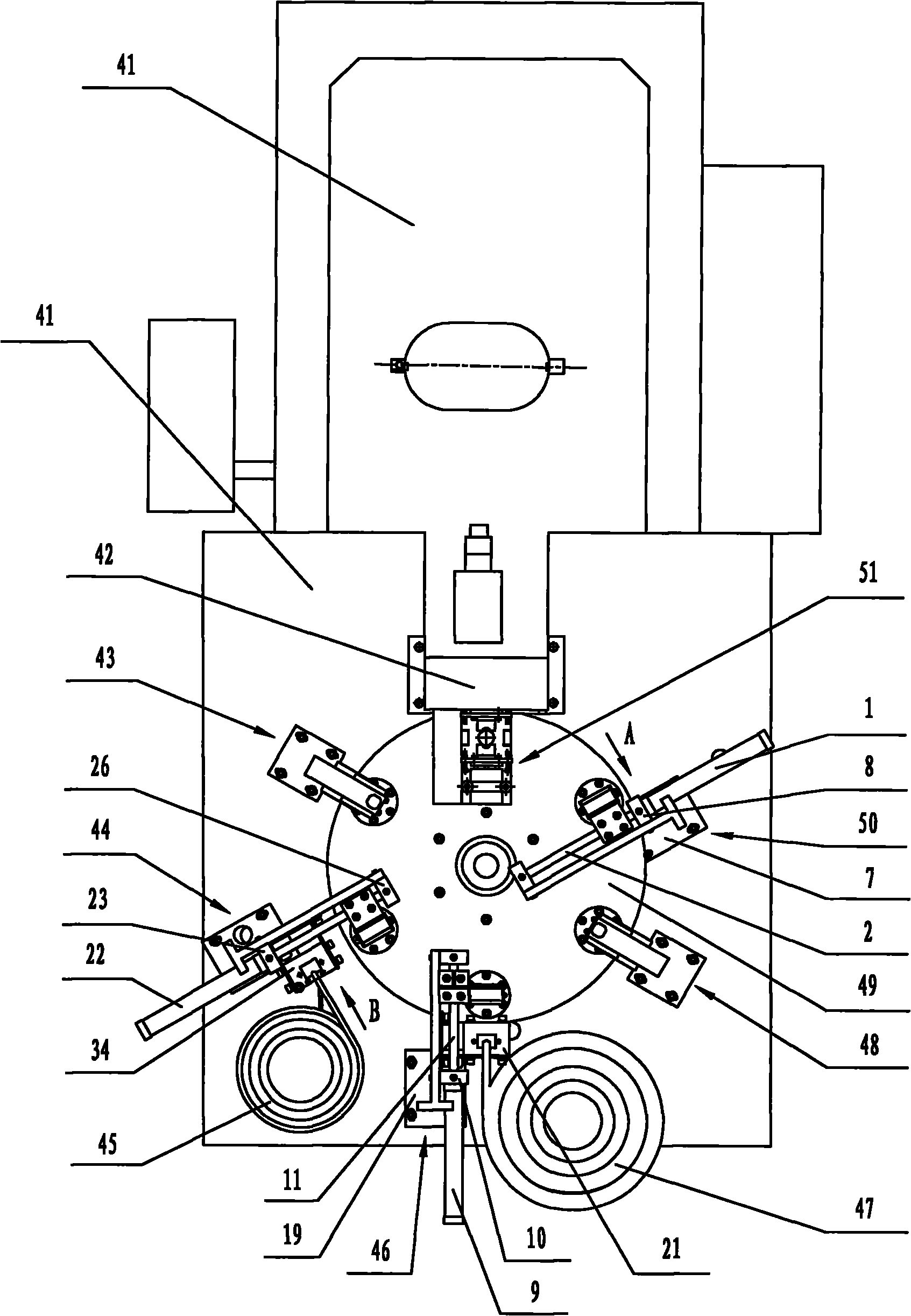

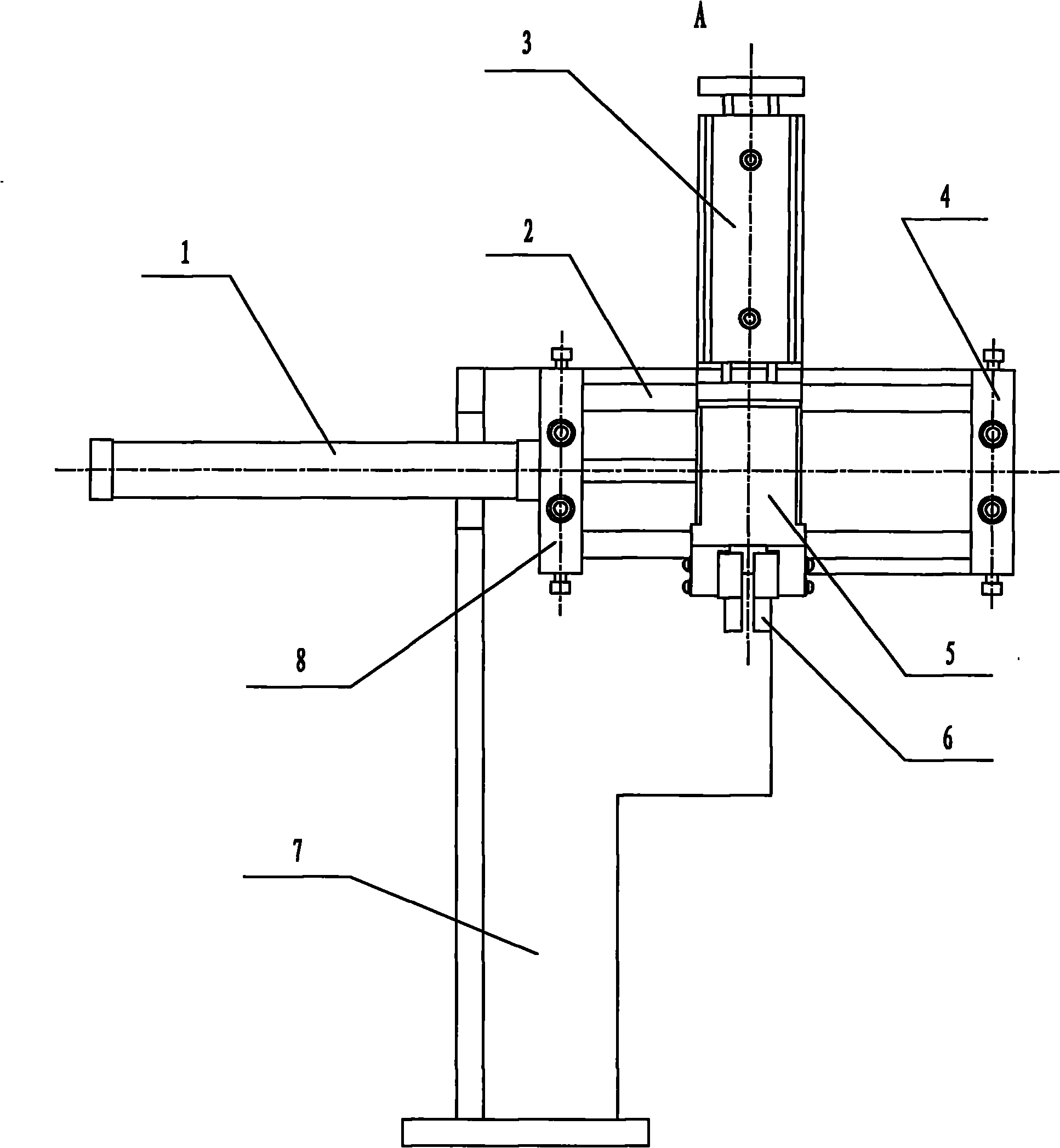

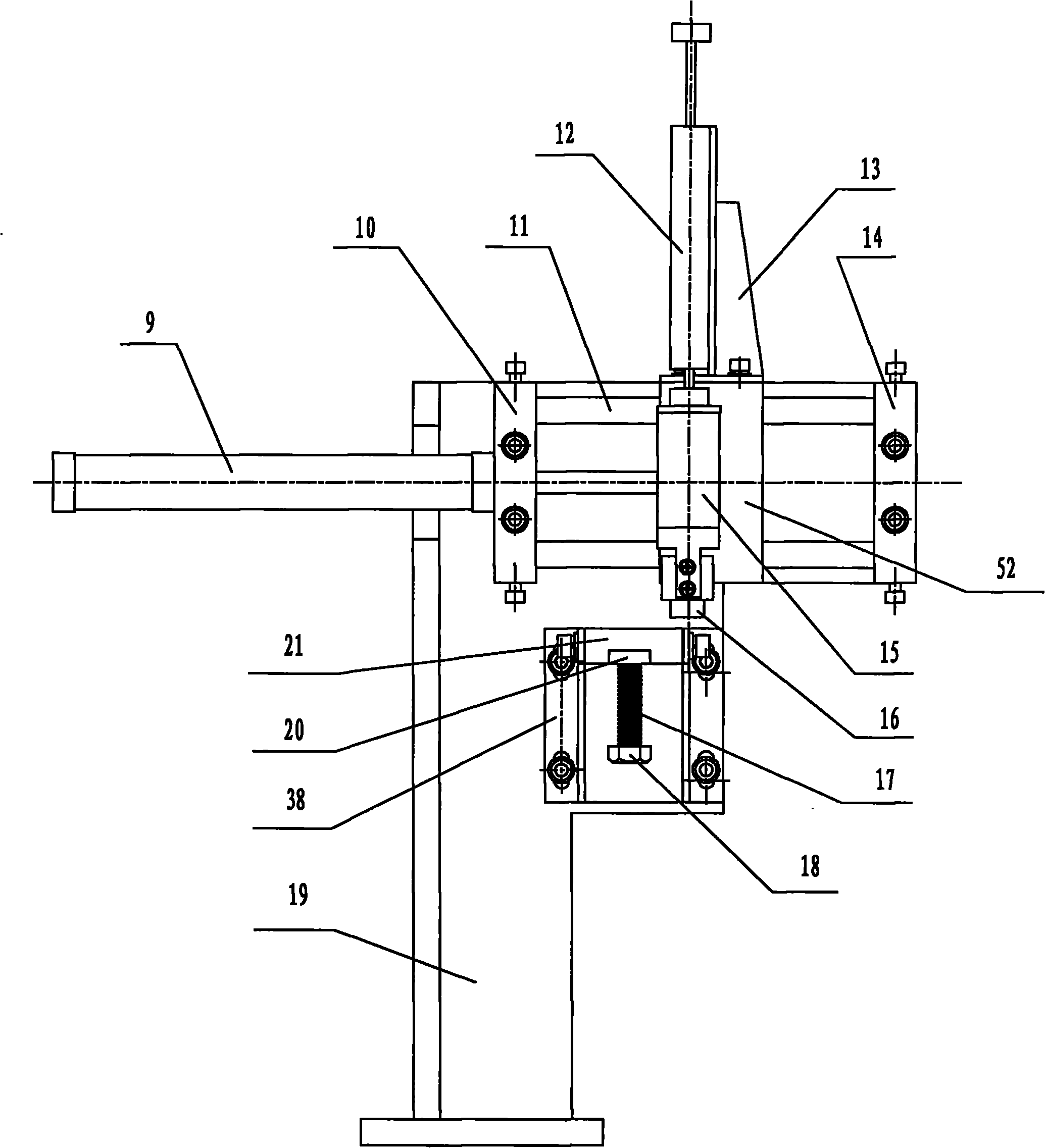

[0018] The automatic nut welding machine of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments:

[0019] Such as figure 1 As shown, in this specific embodiment, the automatic nut welding machine of the present invention includes a frame 41, an indexing mechanism 49, a head welding assembly 42 connected to the frame 41, and uniformly distributed along the circumference of the indexing mechanism 49. The clamping and positioning mechanism 51, the retrieving mechanism 50, the nut feeding mechanism 46, the head sending mechanism 44, the post-welding detection mechanism 48 for detecting whether the nut has been taken out, and the detection mechanism for detecting whether the nut and the head are in place Detection mechanism 43 before welding. Motor (not shown in the figure), electrical control cabinet (not shown in the figure), solenoid valve seat assembly (not shown in the figure) and PLC programmable co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com